Wear Resistant Overlay Welding Plate

Introduction

We can provide customers with customized wear resistance overlay welding plate. These wear-resistance accessories including crusher hammerhead, discs on the rotor shaft, impact plate and so on. The highest surface hardness of wear resistance overlay welding plate can be more than HRc65.

Materials: Q235A soft steel plate

Parameters:Product model and chemical composition (%)

| Product model | C | Cr | Si | Mn | others | Hardness(HRC) | |

| ZP50 | 2.5-3.8 | 20.0-25.0 | 0.50-1.50 | 0,50-1.50 | / | ≥50 | |

| ZP55 | 3.0-4.5 | 20.0-25.0 | 0.50-1.50 | 0.50-1.50 | Mo0.5-1.0 | ≥55 | |

| ZP60 | 3.5-4.8 | 20.0-25.0 | 0.50-1.50 | 0.50-1.50 | Mo0.5-1.0 | ≥60 | |

| ZP65 | 4.5-5.5 | 18.0-23.0 | 0.50-1.50 | 0.50-1.50 | Mo1.5-2.0 | ≥65 |

Product size that can provide (Unit :mm)

| Product name | Base material | Wearing layer | Overall thickness | Size (L×W) | The minimum radius of curvature |

| ZP50 ZP55 ZP60 | 6 | 4 | 10±1 | 1430×3450 | R≥150 |

| 5 | 11±1 | 1430×3450 | R≥150 | ||

| 6 | 12±1 | 1430×3450 | R≥150 | ||

| 8 | 4 | 12±1 | 1430×3450 | R≥150 | |

| 5 | 13±1 | 1430×3450 | R≥150 | ||

| 6 | 14±1 | 1430×3450 | R≥150 | ||

| ZP50 ZP55 ZP60 | 10 | 4 | 14±1 | 1430×3450 | R≥150 |

| 5 | 15±1 | 1430×3450 | R≥150 | ||

| 6 | 16±1 | 1430×3450 | R≥150 | ||

| 8 | 18±1 | 1430×3450 | R≥300 | ||

| ZP50 ZP55 ZP60 | 12 | 4 | 16±1 | 1430×3450 | R≥150 |

| 5 | 17±1 | 1430×3450 | R≥150 | ||

| 6 | 18±1 | 1430×3450 | R≥150 | ||

| 8 | 20±1 | 1430×3450 | R≥300 |

Advantages

The overlay welding plate has high wear resistance, which is 20 times than low carbon steel and 5 times than stainless steel and high manganese steel. It has high impact resistance. Good processing ability: wear resistance overlay welding plate can be deformed and welded and it can be processed into various kinds of wear-resistance parts conveniently like common steel plates. According to different working conditions, we can use welding materials with different alloy components for surfacing welding, which can meet the requirements of various working conditions such as impact, corrosion and abrasive wear.

Scan QR to Read

Links:https://www.globefindpro.com/products/29756.html

Links:https://www.globefindpro.com/products/29756.html

Recommended Products

-

YONG-FENG Y32V Hydraulic Hose Crimper Machine

YONG-FENG Y32V Hydraulic Hose Crimper Machine

-

Fat Electric Bike

Fat Electric Bike

-

YONG-FENG Y51V Hydraulic Hose Crimper Machine

YONG-FENG Y51V Hydraulic Hose Crimper Machine

-

Centrifuge Machine

Centrifuge Machine

-

Mobile Crushing Plant

Mobile Crushing Plant

-

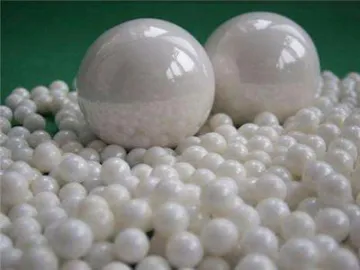

Zirconia Grinding Balls

Zirconia Grinding Balls

-

YONG-FENG Y32S Hand Operated Hydraulic Hose Crimper

YONG-FENG Y32S Hand Operated Hydraulic Hose Crimper

-

TG-F003 Electric Folding Bike

TG-F003 Electric Folding Bike

-

TG-F001 Portable Folding Electric Bike

TG-F001 Portable Folding Electric Bike

-

TG-F005 Electric Folding Bike

TG-F005 Electric Folding Bike

-

TG-F002 Folding Electric Bike

TG-F002 Folding Electric Bike

-

YONG-FENG Y51S Manual Crimping machine for Hydraulic Hose

YONG-FENG Y51S Manual Crimping machine for Hydraulic Hose