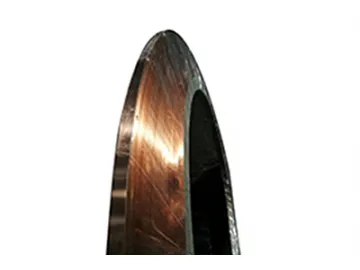

Ni60Cr15 High Resistance Alloy

Introduction:

Ni60Cr15 resistance alloy is made of nichrome alloy, with high resistivity, good oxidation resistance, good stability and ductility and good welding performance. Its maximum operating temperature is 1150℃ and its service life is longer than FeCrAl alloy.

| Style | Specification | ||

| Wire | Diameter: 0.03mm-8mm | ||

| Flat strip | Width: 0.4-40 | Thickness: 0.03-2.9mm | |

| Strip | Width: 8-250mm | Thickness: 0.1-3.0 | |

| Foil | Width: 6-120mm | Thickness: 0.003-0.1 | |

| Rod | Diameter: 8-100mm | Length: 50-1000 | |

Application

Ni60Cr15 resistance alloy has been widely used in metal casing elements like hot plate, gridiron, oven, storage heater, the coil of clothes dryer, fan heater, hand dryer and various resistors.

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Other |

| ≤ | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 15.0~18.0 | 55.0~61.0 | ≤0.50 | Bal. | - |

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Density (g/cm3) | Resistivity (20℃) (Ω·mm2/m) | Heat conductivity (20℃) (W/(m·K)) | Average linear expansion coefficient (20℃-1000℃) (1/℃) | Specific heat capacity (20℃) (J/( kg℃)) | Melting point (℃) | Max. operating temperature (℃) | Magnetism |

| 370 | 730 | 35 | 8.2 | 1.12 | 13 | 17x10-6 | 0.46 | 1390 | 1150 | Non |

| 20℃ | 100℃ | 200℃ | 300℃ | 400℃ | 500℃ | 600℃ |

| 1 | 1.011 | 1.024 | 1.038 | 1.052 | 1.064 | 1.069 |

| 700℃ | 800℃ | 900℃ | 1000℃ | 1100℃ | 1200℃ | 1300℃ |

| 1.073 | 1.078 | 1.088 | 1.095 | 1.109 | - | - |

Index

nickel chromium alloy, resistance wire, alloy strip, NiCr alloy

Scan QR to Read

Links:https://www.globefindpro.com/products/30038.html

Links:https://www.globefindpro.com/products/30038.html

Recommended Products

Hot Products