Semi-automatic Flatbed Die Cutting Machine, MWB-Q Series

The semi-automatic flatbed die cutter is built for wide stock range, high flexibility on production and large format jobs. This die cutting machine is able to handle corrugated board, plastic board and cardboard for POP/POS display jobs, packaging boxes and plastic board converting and etc. Effective feeder with automatic pile lifting system and pre-feeder, offering quick change of sheet pile, and thus increase the efficiency. Center line system offers quick change of jobs and machine set-up. Automatic lubrication system gives less maintenance jobs needed to be done by operator. Knuckle system built with maximum cutting force of 450 tons, is able to cut all the substrates in its stock range. Optimized and enforced toggle system inside flatbed to support this large format 2300x1520mm. Double action stripping or Triple action stripping system available. Safety sensors and devices equipped provides protection for operators from hurt and machine from broken. Heavy and strong cast-iron built machine body for stable and robust performance ( 1850, 2100, 2300) Format available: 1300x980mm, 1480x1080mm, 1650x1200mm, 1850x1400mm, 2100x1500mm, 2300x1500mm Specifications MWB 1300/1300Q (with stripping)

| Model | MWB 1300 | MWB 1300Q (with stripping) |

| Maximum sheet size | 1330x980mm | |

| Minimum sheet size | 550x480mm | |

| Maximum sheet size | 1300x960mm | |

| Maximum cutting pressure | 250 Metric tons | |

| Maximum speed | 4,200 s/h | |

| Stock range | E, B, C, A flute and double wall corrugated up to 7mm | |

| Cutting precision | ±0.5 mm | |

| Height of cutting rule | 23.8 mm | |

| Pressure adjustment range | ±1 mm | |

| Inner chase size | 1330 x 990 mm | |

| Machine size (L x W x H) | 6120x4610x2285mm | 7440 x 4640 x 2500 mm |

| Power | 16.3 kW/ 380V, 3-PH, 50Hz | 17 kW/ 380V, 3-PH, 50Hz |

| Net weight | 15 tons | 17 tons |

| Model | MWB 1450 | MWB 1450Q (with stripping) |

| Maximum sheet size | 1480x1080mm | |

| Minimum sheet size | 550x480mm | |

| Maximum sheet size | 1450x1050mm | |

| Maximum cutting pressure | 300 Metric tons | |

| Maximum speed | 4,200 s/h | |

| Stock range | E, B, C, A flute and double wall corrugated up to 8.5mm | |

| Cutting precision | ±0.5 mm | |

| Height of cutting rule | 23.8 mm | |

| Pressure adjustment range | ±1 mm | |

| Inner chase size | 1480 x 1080 mm | |

| Machine size (L x W x H) | 6330 x 4900 x 2350mm | 7750 x 4860 x 2500 mm |

| Power | 20.5 kW/ 380V, 3-PH, 50Hz | 21 kW/ 380V, 3-PH, 50Hz |

| Net weight | 17 tons | 19 tons |

| Machine Model | MWB 1620 | MWB 1620Q (with stripping) |

| Maximum sheet size | 1650 x 1210mm | |

| Minimum sheet size | 650 x 550mm | |

| Maximum cutting size | 1620 x 1190mm | |

| Maximum cutting pressure | 300 T | |

| Stock range | E, B, C, A flute and double wall up to 9mm | |

| Cutting precision | ±0.5mm | |

| Maximum speed | 3,600 s/h | |

| Pressure adjusting range | ±1mm | |

| Minimum front waste | 10mm | |

| Inner chase size | 1646 x 1220mm | |

| Machine size (L*W*H) | 6600 x 5300 x 2600mm | 8200x5300x2600mm |

| Power consumption | 20.5kW | 21kW |

| Power supply | 380V/ 3-PH, 50Hz | 380V/ 3-PH, 50Hz |

| Net weight | 22T | 24T |

| Machine Model | MWB 1850 | MWB 1850Q (with stripping) |

| Maximum sheet size | 1880x1420mm | |

| Minimum sheet size | 650x550mm | |

| Maximum cutting size | 1850x1400mm | |

| Maximum cutting pressure | 350 T | |

| Stock range | E, B, C, A flute and double wall up to 9mm | |

| Cutting precision | ±0.5mm | |

| Maximum speed | 3,200 s/h | |

| Pressure adjusting range | ±1mm | |

| Minimum front waste | 10mm | |

| Inner chase size | 1890x1430mm | |

| Machine size (L*W*H) | 7200x5900x2600mm | 8600x5900x2600mm |

| Power consumption | 24kW | 25kW |

| Power supply | 380V/ 3-PH, 50Hz | 380V/ 3-PH, 50Hz |

| Net weight | 26T | 28T |

| Machine Model | MWB 2100 | MWB 2100Q (with stripping) |

| Maximum sheet size | 2100x1520mm | |

| Minimum sheet size | 650x550mm | |

| Maximum cutting size | 2080x1500mm | |

| Maximum cutting pressure | 400 T | |

| Stock range | E, B, C, A flute and double wall corrugated sheets up to 9mm | |

| Cutting precision | ±0.5mm | |

| Maximum speed | 3,000 s/h | |

| Pressure adjusting range | ±1mm | |

| Minimum front waste | 10mm | |

| Inner chase size | 2110x1510mm | |

| Machine size (L*W*H) | 7760x6280x2820mm | 9600 x 6280 x 2820mm |

| Power consumption | 32kW | 34kW |

| Power supply | 380V/ 3-PH, 50/Hz | 380V/ 3-PH, 50/Hz |

| Net weight | 31T | 34T |

| Machine Model | MWB 2300 | MWB 2300Q (with stripping) |

| Maximum sheet size | 2300x1520mm | |

| Minimum sheet size | 650x550mm | |

| Maximum cutting size | 2270x1500mm | |

| Maximum cutting pressure | 450 T | |

| Stock range | E, B, C, A flute and double wall corrugated sheets up to 9mm | |

| Cutting precision | ±0.5mm | |

| Maximum speed | 3,000 s/h | |

| Pressure adjusting range | ±1mm | |

| Minimum front waste | 10mm | |

| Inner chase size | 2300x1510mm | |

| Machine size (L*W*H) | 7760x6600x2820mm | 9600x6600x2820mm |

| Power consumption | 32.5kW | 35kW |

| Power supply | 380V/ 3-PH, 50/Hz | 380V/ 3-PH, 50/Hz |

| Net weight | 34T | 37T |

1.Feeding Section

Effective manual feeding system.

Automatic sheet pile lifting system.

Side guide to position paper pile center.

Applicable to E, B, C, A flute and double wall.

2.Die Cutting Section

The centerline system is used for a quick cutting die set up and job changeover.

A pneumatic lock up system ensures safe and operator friendly changeover of the die cutting plate.

3. Stripping Section

Three sides and the middle of the board can be stripped.

An electrically controlled auto-lifter controls the upper stripping tool when stripping is not needed.

The centerline system is used for a quick stripping die set up and job changeover.

4.Delivery Section

Optional function: tape inserter .

Side and front joggers to ensure neat stacking.

Two delivery options available: pallet or trailer.

Photoelectric detective device for safety entrance and operation.

5.Electrical Control Section

The electrical control system uses the latest Siemens PLC technology for a trouble free machine operation.

We also use electric components from internationally known brands for local and quick service and maintenance.

6. Main Drive Chain

A heavy load and highly precise chain achieve a high tensile strength and wear resistance.

7. Main Driving System

A mono-block casting chassis reduces vibration and achieves a more stable performance, as well as a longer lifespan.

A deepened oil tank allows part of the worm wheel to work under lubrication oil for a better all-around lubrication.

Links:https://www.globefindpro.com/products/3005.html

-

LB350 Continuous Extrusion Machine for Aluminum Wire

LB350 Continuous Extrusion Machine for Aluminum Wire

-

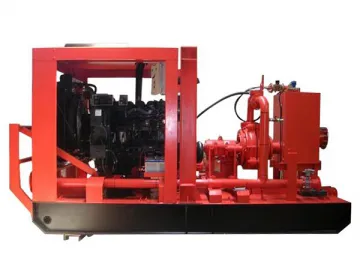

Fire Pump System in Bangladesh

Fire Pump System in Bangladesh

-

LJ300AT Continuous Extrusion Machine for Aluminum Bus Bar

LJ300AT Continuous Extrusion Machine for Aluminum Bus Bar

-

Centrifugal Slurry Pump

Centrifugal Slurry Pump

-

Aluminum Bathroom Cabinet

Aluminum Bathroom Cabinet

-

Aluminum Casement Door, Outward Opening, GDM65

Aluminum Casement Door, Outward Opening, GDM65

-

TJ300T Copper Flat Wire Line

TJ300T Copper Flat Wire Line

-

TJ630 Continuous Extrusion Machine for Copper Busbar

TJ630 Continuous Extrusion Machine for Copper Busbar

-

LJ350T Continuous Extrusion Machine for Aluminum Bus Bar

LJ350T Continuous Extrusion Machine for Aluminum Bus Bar

-

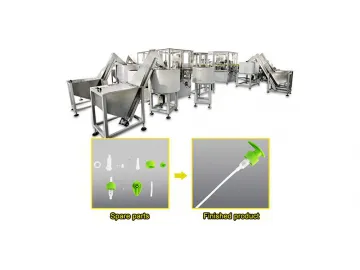

Lotion Pump Assembly Line

Lotion Pump Assembly Line

-

LJ350T Continuous Extrusion Machine for Aluminum Tube

LJ350T Continuous Extrusion Machine for Aluminum Tube

-

Sprayer Trigger Assembly Line

Sprayer Trigger Assembly Line