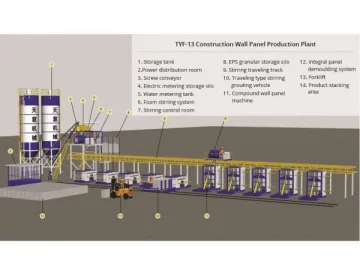

TYF-13 Construction Wall Panel Production Plant

TYF-13 construction wall panel production plant is mainly used to produce various specifications of GRC lightweight wall panels and magnesite wall panels. The suitable materials include cement, sand, fly ash, magnesite, ceramsite and EPS polystyrene particles. Cement can be cured in totally sealed pressure environment, making the hydration reaction more ideal and thus getting higher strength.

This production line adopts PLC control system during the processes from batching, stirring, pumping to demoulding, ensuring the precise batching and uniform stirring. Besides, the labor cost is reduced and the production efficiency is improved.

Patent number: ZL201320012681.4

Specifications of produced wall panels| One-time molding quantity | Thickness | Width | Length |

| 20 | 75mm | 610mm | 2440/3000mm |

| 20 | 90mm | ||

| 16 | 120mm | ||

| 12 | 150mm |

Note: The above dimensions are normal ones. TANY can provide customized production lines according to your requirements for special wall panel sizes.

Main equipmentTYF13 wall panel machine

TYF13 wall panel machine is highly automatic and the production efficiency is high with 20 pieces of panels produced one time. It adopts hydraulic mold opening and closing design so that the panels can demould at one time, which can avoid the panel damage during demoulding process and ensure the stability of product quality.

The side board of the machine is made of special steel sheet, increasing the equipment service life of production line.

Stirring system

Our independently developed large stirring equipment is equipped with precise automatic batching system which can precisely feed and can also stir the slurry more uniformity based on the material properties.

Mobile grouting system

Sealed pumping grouting system can increase the grouting speed and increase the density.

Automatic stacking machine

The demoulding system hydraulically flips the wall panels by 90 degrees, making it convenient for packaging and forklift transfering. Compared with traditional manual demoulding method, this can largely decrease the breakage rate of products.

| Model | TYF13 |

| Overall dimension | 2990L×3050W×1880H mm |

| Power of vibration system | 0.75 kW |

| Power of hydraulic system | 3 kW |

| Hydraulic working pressure | 8 MPa |

| Maximum hydraulic working pressure | 16 MPa |

| Hydraulic oil tank volume | 60 L |

| Structural components | Host machine, hydraulic system, power system, heating system, vibration system, molding battens |

| Total area | 3500*2900mm |

| Stirring volume | 2000L |

| Stirring speed | 32.5r/min |

| Particle diameter | |

| Powder feeding pneumatic butterfly valve | DN300 |

| Stirring period | 10-15min |

| Screw conveying power | 11kw*2 |

| Pumping pressure in theory | High pressure | 0.5 Mpa |

| Low pressure | 0.4 Mpa | |

| Transport capacity in theory | High pressure | 5 Mpa |

| Low pressure | 9.4 Mpa | |

| Max. transport distance | Horizontal | 300 mm |

| Vertical | 120 mm | |

| Main motor power | 7.5 kW | |

| Hopper volume | 2m³ | |

| Loading height | 1000 mm | |

| Hydraulic oil tank volume | 60 L | |

| Distribution valve form | Ball valve | |

| Main Machine Weight | 500kg | |

| Frame size: L×W×H | 1785×960×1700mm | |

Close

| Model | TY-13 |

| Overall dimension | 4500L×4600W×1050H mm |

| Total power | 7 kW |

| Demoulding motor power | 5.5 kW |

| Travel motor power | 1.5 kW |

| Hydraulic system motor power | 4 kW |

| Hydraulic working pressure | 10 Mpa |

| Maximum hydraulic working pressure | 16 Mpa |

| Stacking platform | 4500L×2300W mm |

Close

Index

construction partition wall, precast wall panel, wall production line, interior wall machines

Links:https://www.globefindpro.com/products/30492.html

-

Horizontal Belt Conveyor

Horizontal Belt Conveyor

-

Automatic Paint Spraying Machine

Automatic Paint Spraying Machine

-

-

3D DVI Cable

3D DVI Cable

-

VGA to BNC Cable

VGA to BNC Cable

-

DVI Extension Cable

DVI Extension Cable

-

Triple UV Curing Machine

Triple UV Curing Machine

-

Single Roller Paint Coating Machine

Single Roller Paint Coating Machine

-

Precast Concrete Production Equipment and Molds

Precast Concrete Production Equipment and Molds

-

Double UV Curing Machine

Double UV Curing Machine

-

Automatic Loading Conveying Equipment

Automatic Loading Conveying Equipment

-

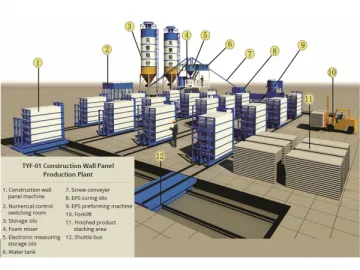

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)

TYF-01 Construction Wall Panel Production Plant (Calcium Silicate Board Compound Wall Panel, Partition Wall)