Coal Fired Steam Boiler System

Rated steam output: 20-35ton/h

Rated working pressure: 1.25-2.5Mpa

Fuel type: anthracite coal, meagre coal, lignitous coal, bituminous coal

The coal fired steam boiler system is a large industrial bulk boiler. Due to limitations of volume and transportation, we transport parts of the boiler in pieces and customers can assemble them on site. We can provide technicians to provide on-site installation and debugging services upon request.

The boiler is fueled by coal and it effectively heats the water within, evaporating it so that it can condense within a heat exchanger and the cycle continues. It can provide heat for manufacturing equipment or as generalized heating in large structures.

The steam boiler is widely used in industry, and its main applications include:

Food industry: The steam can be used for cleaning, and can be used for heating, drying or disinfecting food.

Spinning, printing and dyeing industry: used for some production links such as dyeing, rinsing, drying and shaping cloth.

Biological medicine industry: used for heating reaction kettles, condensation reaction, exchanging heat and disinfecting of chemical reaction systems.

Hospital: used for disinfecting, heating, and air conditioning.

Petrochemical Industry: used for heating oil and increasing liquidity.

Wood furniture industry: used for drying wood, brick and so on

Papermaking industry: high pressure steam is used to drive power generation. The steam after decompressing is used for drying, and the last low pressure steam is used for deinking or pulping and making paper.

Tobacco industry: provide heat for making silk and baking. Technical parameters:

| Type | Rated steam output(ton/hr) | Rated steam pressure(MPa) | Rated steam temperature(℃) | Design thermal efficiency |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 193/204/226/247 | >78% |

| SZL20 | 20 | |||

| SZL25 | 25 | |||

| SZL30 | 30 | |||

| SZL40 | 40 | |||

| SHL50 | 50 | |||

| SHL65 | 65 | |||

| SHL75 | 75 |

The industrial boiler is a natural circulation boiler which is divided into two parts. The upper part is a boiler heated surface, and under part is a grate. The economizer and air per-heater are set at the tail of the boiler. The boiler features a water circulation system, flue gas system, ash system and blowing system.

1. Boiler heated surface

The boiler heated surface consists of a steam drum, water drum, header, water wall and convection tube bundle. Water drum is equipped with sewage device.

2. Grate

The boiler uses chain grate and wind blows from the bottom. There are 6 independent wind chambers under the grate, which can be adjusted according to the user combustion conditions to save electricity.

3. Economizer

The economizer is placed at the tail of boiler, which is used to recover the residual heat of flue gas. When the temperature of exhaust gas is too high, the economizer can reduce the temperature and can save fuel.

4. Air per-heater

The air pre-heater can heat the air before entering the boiler and improve combustion efficiency.

5. Water circulation system

Water source—pump—economizer—drum—downcomer-- water drum-- riser tube-- steam drum-- steam outlet

6. Ash system

The fuel ash after burning is discharged by the slag extractor at the end of grate, ash not timely discharged will fall into front ash bucket with chain grate running. So users need to clean regularly.

Links:https://www.globefindpro.com/products/30767.html

-

Oil and Gas Fired Hot Water Boiler

Oil and Gas Fired Hot Water Boiler

-

Flue Gas Waste Heat Recovery Boiler

Flue Gas Waste Heat Recovery Boiler

-

Horizontal Coal Fired Hot Water Boiler

Horizontal Coal Fired Hot Water Boiler

-

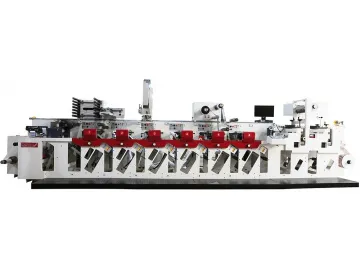

F3 Flexo Printing Press

F3 Flexo Printing Press

-

High Pressure Steam Boiler

High Pressure Steam Boiler

-

Flexible Foam High Pressure Polyurethane Foaming Machine

Flexible Foam High Pressure Polyurethane Foaming Machine

-

Circulating Fluidized Bed Boiler

Circulating Fluidized Bed Boiler

-

Oil and Gas Fired Thermal Oil Boiler

Oil and Gas Fired Thermal Oil Boiler

-

Vertical Coal Fired Thermal Oil Boiler

Vertical Coal Fired Thermal Oil Boiler

-

Swimming Hand Paddle

Swimming Hand Paddle

-

Biomass Fired Steam Boiler

Biomass Fired Steam Boiler

-

Coal Fired Utility Boiler

Coal Fired Utility Boiler