Bottom Loading Arm with API Coupler

Inquiry

Specifications

This loading arm can be directly mounted on the ground foundation, offering the advantages of compact structure and small footprint;

Rational layout allows for smooth operation without interference;

Constructed with steel and aluminum alloy, providing lightweight and robust structure;

Dry disconnect coupling permits easy operations, possible risks associated with leakage or dripping during loading and unloading can be avoided;

Due to the tank is filled from the bottom, the volatilization of liquid can be minimized;

Vapor return line helps achieve zero vapor emission during the loading and unloading process;

Composite drop hose or metal drop hose is employed for flexible connection between the loading arm and the tanker;

Spring cylinder balancing system keeps the outboard arm and parts of front end counterbalanced, providing the loading arm with smooth up/down movement;

Configured with anti-static device, efficiently eliminating the static charges and stray currents caused by liquid flowing through pipes during the loading and unloading operations;

These bottom loading arms are used to load and unload road and railway tankers for a range of industrial fluids at liquid transfer terminals. The API coupler allows for fast connection and leak-free transfer of fluids, while ensuring safe operation.

Specifications

Nominal diameter: DN50~DN100

Design pressure: 0.1MPa~1.0MPa

Design temperature: -30℃~ 100℃

Pipeline material: carbon steel/stainless steel/aluminum alloy

This loading arm can be directly mounted on the ground foundation, offering the advantages of compact structure and small footprint;

Rational layout allows for smooth operation without interference;

Constructed with steel and aluminum alloy, providing lightweight and robust structure;

Dry disconnect coupling permits easy operations, possible risks associated with leakage or dripping during loading and unloading can be avoided;

Due to the tank is filled from the bottom, the volatilization of liquid can be minimized;

Vapor return line helps achieve zero vapor emission during the loading and unloading process;

Composite drop hose or metal drop hose is employed for flexible connection between the loading arm and the tanker;

Spring cylinder balancing system keeps the outboard arm and parts of front end counterbalanced, providing the loading arm with smooth up/down movement;

Configured with anti-static device, efficiently eliminating the static charges and stray currents caused by liquid flowing through pipes during the loading and unloading operations;

Scan QR to Read

Links:https://www.globefindpro.com/products/3204.html

Links:https://www.globefindpro.com/products/3204.html

Recommended Products

-

Screw On Spout, LW097

Screw On Spout, LW097

-

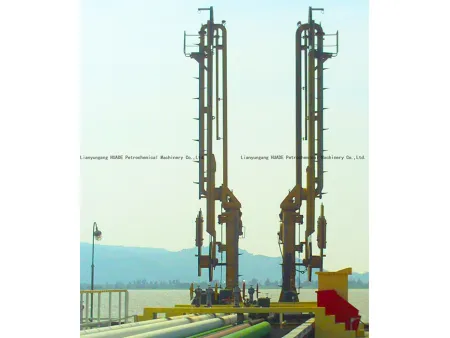

Marine Loading Arm (Manual Operation)

Marine Loading Arm (Manual Operation)

-

Screw On Spout, LW098

Screw On Spout, LW098

-

Top Loading Skid

Top Loading Skid

-

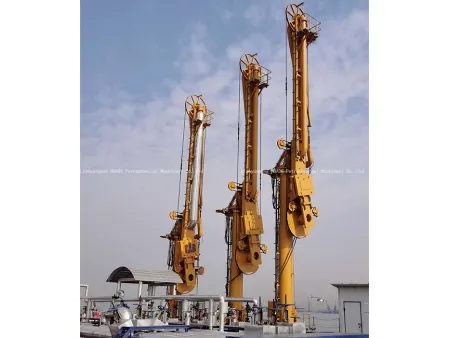

Marine Loading Arm (Hydraulic Operation)

Marine Loading Arm (Hydraulic Operation)

-

Screw On Spout, LW092

Screw On Spout, LW092

-

THVA-63 over and under voltage, over current protection relay, 40A 63A rated current

THVA-63 over and under voltage, over current protection relay, 40A 63A rated current

-

Screw On Spout, LW084

Screw On Spout, LW084

-

Single Arm Top Loading Arm

Single Arm Top Loading Arm

-

Gangways

Gangways

-

Qatar--Concrete cooling 30 tons flake ice system

Qatar--Concrete cooling 30 tons flake ice system

-

Maldives--Containerized plate ice machine and ice storage

Maldives--Containerized plate ice machine and ice storage

Hot Products