NTS3 CNC Last Turning Machine

Description

The Veansan NTS3 CNC last turning machine is designed with a touch screen to operate conveniently and with ease. It can be used to process lasts made from various materials such as polyethylene and aluminum. The machine is capable of producing three pairs of lasts at the same time, which is quite efficient.

| Dimension | 2700mm(L)*1900mm(W)*2550mm(H) |

| Processing speed | 75 rpm |

| Processing length | 50mm - 380mm |

| Actual power consumption | 12KW--16.8KW |

| Workstation | 6 (three pairs) |

| Size range | ±5 size |

| System version | 3.6.6.8D.2 |

| File format support | STL IGS MOD NC |

Features

1. NTS3 CNC last turning machine carves the front part of shoe last directly and precisely without polishing.

2. Adoption of the DOM electronic disk for the system storage carrier provides increased stability compared to traditional hard disks. It has an advanced fault processing system to ensure the security of the data.

3. Three sets of cutting heads and six stations are available, which are able to produce three pairs of lasts at the same time.

4. The fine processing has no belt and each high speed servo motor controls a cutting shaft to guarantee neat and smooth lines.

5. Accurate profiling and high precision.

6. Equipped with robotic arms for optimal efficiency and precision.

VEANSAN is a reputable CNC shoe machine designer, CNC last turning machine manufacturer since 1985, we are contributed to the shoe making industry. There are wood, plastic and aluminum shoe last made by the CNC last turning machine. To make quality shoe last, we use CNC milling and turning machines to ensure precision. We can provide design sketch to the final footwear product as well as custom solutions.

Links:https://www.globefindpro.com/products/32283.html

-

VDS2-Z CNC Last Turning Machine

VDS2-Z CNC Last Turning Machine

-

Power Wheel Planetary Gear Drive (American Standard Size)

Power Wheel Planetary Gear Drive (American Standard Size)

-

Shoe Last Gluing Machine

Shoe Last Gluing Machine

-

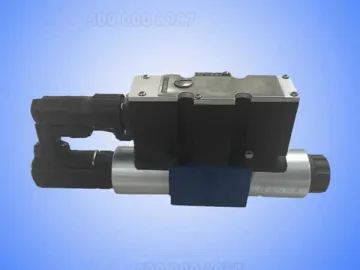

Proportional Directional Valve, Direct Operated with Electrical Position Feedback, HD-4WRE (E)

Proportional Directional Valve, Direct Operated with Electrical Position Feedback, HD-4WRE (E)

-

Bamboo Pulp Molding Machine

Bamboo Pulp Molding Machine

-

4/2 and 4/3 Proportional Directional Valve, Pilot Operated without Electrical Position Feedback, HD-4WRZ(E)

4/2 and 4/3 Proportional Directional Valve, Pilot Operated without Electrical Position Feedback, HD-4WRZ(E)

-

Pulp Cup Forming Machine

Pulp Cup Forming Machine

-

Reed Pulp Molding Machine

Reed Pulp Molding Machine

-

Fixed Displacement Hydraulic Pump

Fixed Displacement Hydraulic Pump

-

Pulp Tray Forming Machine

Pulp Tray Forming Machine

-

Paper Noodle Box

Paper Noodle Box

-

Variable Displacement Hydraulic Pump

Variable Displacement Hydraulic Pump