VDS2-Z CNC Last Turning Machine

Description

The VDS2-Z CNC last turning machine features two cutting heads and four stations, which are able to produce two pairs of lasts simultaneously. A direct connection design of a high speed servo motor and straight cutter shaft has been adopted to ensure each servo drive can control a knife shaft. This is up to 5 times faster than previous models. With a simple changeover of blades, different materials such as polyethylene, wood, aluminum, and foam can be processed. The machine is operated with a touch screen.

Application

The VDS2-Z CNC last turning machine can produce polythene and aluminum shoe lasts, wooden hangers, soles, handles and more. It can produce two pairs of lasts at the same time.

| Model | VDS2-Z |

| Workstation | 4 |

| Size range | ±5 size |

| Machining length | 50mm - 380mm |

| Spindle speed | 9500 rpm |

| Maximum processing speed | 75 rpm |

| Actual power | 12KW |

| Scanning resolution | 5um |

| Dimension | 2450(L)mm*1640(W)mm*2300(H)mm |

| File format support | STL IGS MOD NC |

Features

1. The DS2-Z CNC last turning machine has two sets of cutting heads and four stations, which are able to produce two pairs of lasts at the same time.

2. One cutting head is used for rough machining (30 seconds) and the other cutting head is designed for fine processing. Thus, the whole process will be completed within 4 minutes.

3. A direct connection design of high speed servo motor and straight cutter shaft has been adopted to make sure each servo drive can control a knife shaft with a speed of 9500 rpm.

4. A scanning function with scanning resolution 5um.

5. The small cutter head has no belt, and the speed is uniform.

6. The lines are neat, bright and smooth after carving with precision.

7. Accurate profiling and high precision.

8. Lower power consumption compared to other last turning machines.

VEANSAN is a recognized CNC shoe machine designer, CNC last turning machine manufacturer since 1985, we are contributed to the shoe making industry and make quality shoe last for shoemakers. To make quality shoe last, we use CNC milling and turning machines to ensure precision. We can provide design sketch to the final shoe product as well as custom shoemaking solutions, with mission to provide quality footwear machines in client needs.

Links:https://www.globefindpro.com/products/32284.html

-

Power Wheel Planetary Gear Drive (American Standard Size)

Power Wheel Planetary Gear Drive (American Standard Size)

-

Shoe Last Gluing Machine

Shoe Last Gluing Machine

-

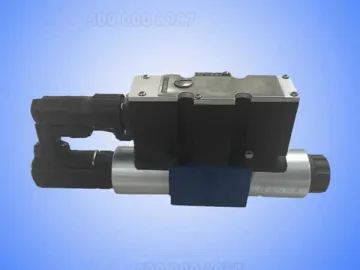

Proportional Directional Valve, Direct Operated with Electrical Position Feedback, HD-4WRE (E)

Proportional Directional Valve, Direct Operated with Electrical Position Feedback, HD-4WRE (E)

-

Bamboo Pulp Molding Machine

Bamboo Pulp Molding Machine

-

4/2 and 4/3 Proportional Directional Valve, Pilot Operated without Electrical Position Feedback, HD-4WRZ(E)

4/2 and 4/3 Proportional Directional Valve, Pilot Operated without Electrical Position Feedback, HD-4WRZ(E)

-

Hydraulic Double Throttle Check Valve

Hydraulic Double Throttle Check Valve

-

NTS3 CNC Last Turning Machine

NTS3 CNC Last Turning Machine

-

Pulp Cup Forming Machine

Pulp Cup Forming Machine

-

Reed Pulp Molding Machine

Reed Pulp Molding Machine

-

Fixed Displacement Hydraulic Pump

Fixed Displacement Hydraulic Pump

-

Pulp Tray Forming Machine

Pulp Tray Forming Machine

-

Paper Noodle Box

Paper Noodle Box