PP-R drinking water pipe(Polypropylene Random Pipe)

Conventional colors: white, green, and grey

Diameter of pipe caliber: 20-160mm

| Outside Diameter(mm) | Wall thickness(mm) | |||

| Standard work pressure | ||||

| S5(PN1.25) | S4(PN1.6) | S3.2(PN2.0) | S2.5(PN2.5) | |

| 20 | 2.0 | 2.3 | 2.8 | 3.4 |

| 25 | 2.3 | 2.8 | 3.5 | 4.2 |

| 32 | 3.0 | 3.6 | 4.4 | 5.4 |

| 40 | 3.7 | 4.5 | 5.5 | 6.7 |

| 50 | 4.6 | 5.6 | 6.9 | 8.3 |

| 63 | 5.8 | 7.1 | 8.7 | 10.5 |

| 75 | 6.9 | 8.4 | 10.3 | 12.5 |

| 90 | 8.2 | 10.1 | 12.3 | 15.0 |

| 110 | 10.3 | 12.2 | 15.1 | 18.4 |

| 160 | 14.6 | 17.9 | 21.9 | 26.6 |

Performance

1. Hygienic and non-toxic: PPR material, a kind of environmental protection building material products, is applicable for pure drinking water pipe system.

2. Heat resistance: PPR pipe can transport water of which the temperature can reach 95℃ under long-term continuous working pressure.

3. Corrosion resistance: the surface of the pipe made of PPR material is smooth, which can prevent the pipeline from fouling and clogging as well as the basin and bathtub from rusting.

4. Heat preservation and energy saving: the thermal conductivity of PPR material is 1/200 of the metal, excellent for heat preservation of hot water pipeline.

5. Lightweight but high intensity: weighting 1/8 of the metal pipe, and the pressure resistance test strength reaching 5MPa (50kg/cm2) above, PPR pipe is with good toughness and impact resistance.

6. Beautiful appearance: smooth inner and outer surface of the pipe, soft color and beautiful figure.

7. Easy installation: using hot fusion connection, without threading, it only takes a few seconds to complete a joint connection.

8. Safe and reliable: PPR pipe uses high quality copper insert to connect with a metal pipeline and a water machine.

9. Long service life: the pipe system can last for more than 50 years under normal use.

Installation

Hot fusion connection technology is adopted in the hot and cold water transportation projects.

PPR pipeline connection uses handheld hot fusion device for hot fusion connection. The installation steps are as follows:

1. Before connecting, dusts and foreign bodies in the pipeline and accessories should be removed first.

2. When the red light is on and not blinking, align the machine to the pipe and pipe fittings to be connected. Directly insert the pipe end into the heating sleeve to reach the preset depth, and push the pipe fittings to the heating head at the same time. When reaching the heating time, the pipe and the pipe fittings are removed the same time and inserted uniformly without rotating into the required depth at once. The uniform flange is thus formed at the joint.

3. After connecting, firmly grip the pipe and pipe fittings for enough cooling time and let go only when cooled to a certain extent.

Links:https://www.globefindpro.com/products/32757.html

-

Fully Automatic Stretch Film Rewinding Machine

Fully Automatic Stretch Film Rewinding Machine

-

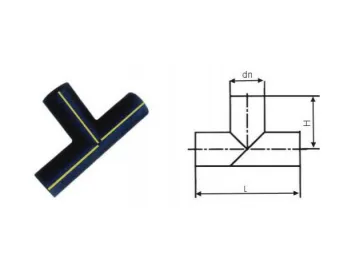

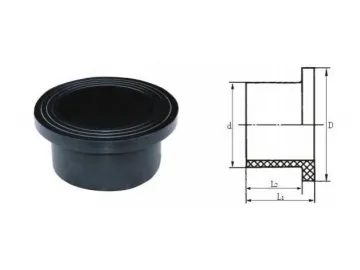

Butt Welding Fittings, HDPE Gas Pipe Fittings

Butt Welding Fittings, HDPE Gas Pipe Fittings

-

Fully Automatic Five Shaft Stretch Film Rewinding Machine

Fully Automatic Five Shaft Stretch Film Rewinding Machine

-

Semi-automatic Aluminum Foil & Cling Film Rewinding Machine

Semi-automatic Aluminum Foil & Cling Film Rewinding Machine

-

Fully Automatic Three Shaft Stretch Film Rewinding Machine

Fully Automatic Three Shaft Stretch Film Rewinding Machine

-

Butt Welding Fittings, HDPE Water Pipe Fittings

Butt Welding Fittings, HDPE Water Pipe Fittings

-

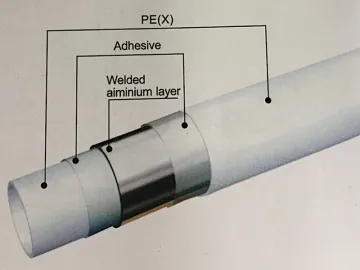

Aluminum Plastic Composite Pipe (PEX-AL-PEX Pipe)

Aluminum Plastic Composite Pipe (PEX-AL-PEX Pipe)

-

Compact Stretch Film Rewinder

Compact Stretch Film Rewinder

-

Fully Automatic Five Shaft Perforator Rewinder

Fully Automatic Five Shaft Perforator Rewinder

-

Three Shafts Aluminum Foil Rewinding Machine

Three Shafts Aluminum Foil Rewinding Machine

-

Butt Fusion Fittings, HDPE Gas Pipe Fittings

Butt Fusion Fittings, HDPE Gas Pipe Fittings

-

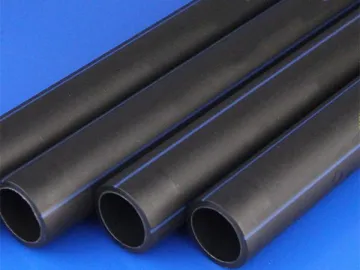

HDPE Pipe (High Density Polyethylene Pipe)

HDPE Pipe (High Density Polyethylene Pipe)