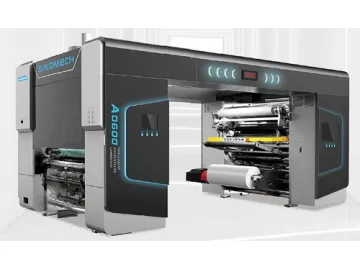

CINOVA Gearless CI Flexo Printing Press

Advantages Quick job changeovers Superior print quality High throughput and productivity Fully-integrated systems Applicable Materials Paper Film Foil Non-wovens Laminates  The operation process of the flexographic printing press is described as follow: Dual-station unwind Corona treating Web guiding 8 colors printing Drying Static image obverse Out feed with cooling system Web guiding Dual-station rewind rtrewindrewindrewind Main Configurations

The operation process of the flexographic printing press is described as follow: Dual-station unwind Corona treating Web guiding 8 colors printing Drying Static image obverse Out feed with cooling system Web guiding Dual-station rewind rtrewindrewindrewind Main Configurations

Unwinding unit

1 set

Printing unit

1 set

Drying system

1 set

Out-feed unit

1 set

Rewinding unit

1 set

Web guide and corona treating device

1 set

Pre-register device

1 set

Control system and operating platform

1 set

Technical Parameters

Get in Touch

This flexo printing machine is 8 colors sleeve type CI (Central Impression) flexo press, which is mainly applied to the printing industry for flexible packaging industry.

Unwinding unit

1 set

Printing unit

1 set

Drying system

1 set

Out-feed unit

1 set

Rewinding unit

1 set

Web guide and corona treating device

1 set

Pre-register device

1 set

Control system and operating platform

1 set

Technical Parameters

| Machine direction | Printing unit is on the left of rewinding unit (see on the operation side) |

| Substrate | BOPP 15~100μm, PE 20~140μm, PET 10~60μm, BOPA 15~60μm, PAPER 30~100gsm, etc. similar material. Remark: The thickness and width for the printing material should match with setting tension. |

| Guide roller width | 1320mm |

| Print width | 1270mm |

| Print unit | 8 colors |

| Printing repeat length | 360 ~ 940mm |

| Print register precision | ±0.1mm |

| Tension control range | 50~ 600 N/full web |

| Plate thickness | 1.7mm, 1.143mm |

| Adhesive tape thickness | 0.38mm, 0.5mm |

| Max. mechanical speed | 450m/min |

| Running speed | 15 ~ 400m/min, subject to the following factors: - Substrate - Ink and solvent - Print image and print quality |

| Ink type | Water based ink, alcohol-soluble ink or solvent based ink |

| Drive method for printing unit | Servo motor drive |

| Register control | Servo motor control |

| Print cylinder, aniox roller | Sleeve type |

| Max. un/rewind diameter | ⌀ 800mm |

| Heating & drying system | Electricity/gas/steam/oil heating, frequency conversion control for air speed |

| Motor power | About 160kW (usually use 60%) |

| Electric heating | 228kW (It can do infinitely variable adjustment) |

| Max. Noise | Below 85 dB |

| Machine color | Gray & white, please refer to the machine photo |

Scan QR to Read

Links:https://www.globefindpro.com/products/3447.html

Links:https://www.globefindpro.com/products/3447.html

Recommended Products

-

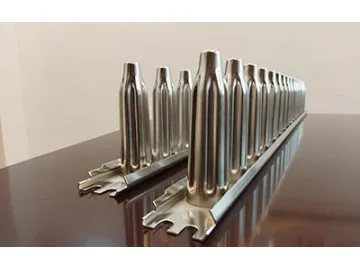

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-1

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-1

-

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-3

Versaline 16 Lane Ice Cream Equipment Stainless Steel Ice Pop Mold-3

-

Solventless Laminator (for Carton Box)

Solventless Laminator (for Carton Box)

-

Vibratory Screener & Vibrating Sieve, ZS Series

Vibratory Screener & Vibrating Sieve, ZS Series

-

Solventless Laminator (for Cheese Stick Packaging)

Solventless Laminator (for Cheese Stick Packaging)

-

Multi-Directional Motion Mixer, HD Series

Multi-Directional Motion Mixer, HD Series

-

Tube Filling and Sealing Machine

Tube Filling and Sealing Machine

-

Solventless Laminator A400

Solventless Laminator A400

-

Mild Steel Enclosure for Honeywell

Mild Steel Enclosure for Honeywell

-

Digital Solventless Laminator A600D

Digital Solventless Laminator A600D

-

Solventless Laminator A350

Solventless Laminator A350

-

Dust Collecting Crushing Set, WF-C Series

Dust Collecting Crushing Set, WF-C Series

Hot Products