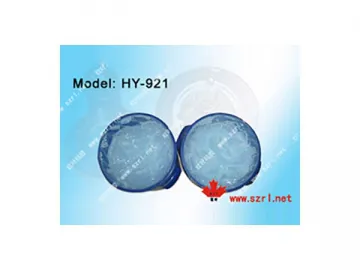

High Transparency Injection Molding Silicone Rubber

Name: High Transparency Injection Molding Silicone Rubber

Number: HY-921

Count: 501

Distribution time: 2010-07-02

Usage: Injection molding for baby nipples, cake mold, medical catheter.

Description

The product is liquid silicone rubber suitable for injecting moulding technique with high transparency, strength, and tear strength. It is mainly used for making silicone products,such as baby nipples, medical tube,etc.

Typical Properties

The HY-921 is an injection molding liquid silicone rubber, which is an elastomer cured under high temperature, has the following excellent properties:

High transparency

Excellent tear strength(≥2.5KN/m)

Good resilience

Good heat stability and weatherability ( temperature resistant range of -60℃ - -250℃)

Anti-yellowing

Heat-ageing resistance

Comply with USA CFR 21.Part.177.2600 and Chapter 4.9 Test Standards for Volatile Compound of EN14350-2 and EU RoHS Standard.

| Item | HY-921 | |

| Appearance | Transparent | |

| Viscosity (Pa.S) | 400 | |

| Density (g/cm3) | 1.07 | |

| Hardness (A°) | 30 | |

| Elongation at break (%) | 400 | |

| Tear strength (KN/m) | 2.5 | |

| Curing condition | After Mixed A with B according to mixing ratio of 1:1, 150mm×150mm×2mm, mould will be formed in 7 minutes under temperature of 150℃ | |

After the component A and component B are mixed under the temperature of 20 ℃, the effective operating time is 5 days in sealing status, The effective operating time will shorten in case of rising temperature.

Instruction

Typical data can not be directly used for actual production guidance. Please contact us for details.

Package

The general packages of HY-92XA/B series is in 20kg and 200kg per barrel.

Other applications

The series of products can also be used for producing other food grade silicone rubber products

Links:https://www.globefindpro.com/products/34855.html

-

Resin Chamfering Wheel-Y3

Resin Chamfering Wheel-Y3

-

Liquid Silicone Rubber for Baby Nipple and Diving Glasses

Liquid Silicone Rubber for Baby Nipple and Diving Glasses

-

Silicon Carbide Polishing Brick

Silicon Carbide Polishing Brick

-

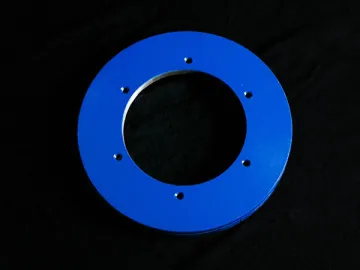

Zinc-aluminum Alloy Craft Silicone Disc HY-456

Zinc-aluminum Alloy Craft Silicone Disc HY-456

-

Metal Bond Diamond Peripheral Squaring Wheel

Metal Bond Diamond Peripheral Squaring Wheel

-

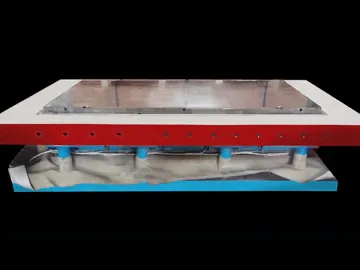

Oil Plate Isostatic Pressing Punch

Oil Plate Isostatic Pressing Punch

-

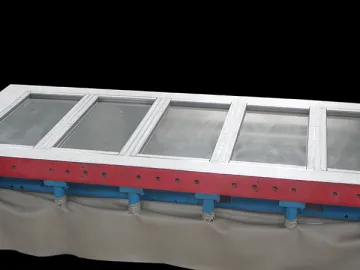

Mold Assembly for Wall Tiles

Mold Assembly for Wall Tiles

-

Mold Assembly for Exterior Wall Tiles

Mold Assembly for Exterior Wall Tiles

-

Rear Diamond Edge Grinding Wheel

Rear Diamond Edge Grinding Wheel

-

201 Methyl Silicone Oil

201 Methyl Silicone Oil

-

Mold Assembly for Polishing Tiles

Mold Assembly for Polishing Tiles

-

HY-918 Pad Printing Silicone Rubber

HY-918 Pad Printing Silicone Rubber