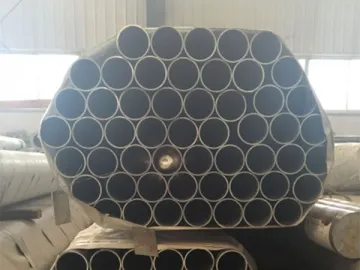

Aluminum Tube

Aluminum Tube for Aircraft Construction, Metal Tube for Storage Tank, Aluminum Tube for Pressure Vessel, Aluminum Alloy for Military Equipment

We will process Aluminum alloy according to the alloy type, specification, heat treatment condition, and other details. Please contact to tell us your requirements.

For commonly used Aluminum and Aluminum alloy please click here:

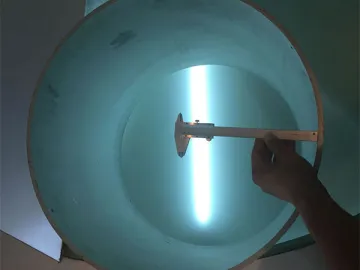

Equipment & Specifications

| Equipment | Product | Outer diameter | Inner diameter |

| 100MN double-action direct extruder | seamless pipe | 225-507mm | 195-435mm |

| 55MN double-action indirect extruder | seamless pipe | 70-265mm | 50-254mm |

| 28MN double-action indirect extruder | seamless pipe | 70-137mm | 35-125 |

| 1880UST double-action direct extruder | seamless pipe | 28-88mm | 14-78mm |

| 1100UST double-action direct extruder | seamless pipe | 25-64mm | 3-55mm |

Recommended Alloy & Applications

7075: for fabricating molds, and high-stress structural parts with high strength and corrosion resistance, like aircraft frame

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others |

| 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | single: 0.05; total: 0.15 |

| Alloy | Mechanical and physical properties | ||||

| tensile strength (25°C) (MPa) | yield strength (25°c) (MPa) | hardness 500kg 10mm | elongation 1.6mm(1/16in) thickness | max shear stress (MPa) | |

| 7075-T651 | 572 | 503 | 150 | 11 | / |

| weldability | machinability | corrosion resistance | electricity conductivity 20℃(68℉) (%IACS) | density (20℃)(g/cm3) | |

| / | / | / | / | 2.82 | |

7050: workpieces with high resistance to corrosion, stress corrosion cracking, and fatigue, as well as high fracture toughness; like metal plates fir airplane frame, extruded parts, free forging and die forgings

7A04: aircraft skin, screws, and force-bearing components like beam girder, frame, wing ribs, alighting gear, etc.

| Alloy | Major alloying element (mass fraction) (%) | ||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | |

| 7075 | 0.4 | 0.5 | 1.2~2.0 | 0.3 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.2 | the rest part |

| 7A04 | 0.5 | 0.5 | 1.4~2.0 | 0.2~0.6 | 1.8~2.8 | 0.1~0.25 | 5.0~7.0 | 0.1 | the rest part |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2~0.7 | 1.0~1.8 | --- | 4.0~5.0 | 0.01~0.06 | the rest part |

| 7039 | 0.3 | 0.4 | 0.1 | 0.1~0.4 | 2.3~3.3 | 0.15~0.25 | 3.5~4.5 | --- | the rest part |

| 7049 | 0.4 | 0.5 | 1.2~1.9 | 0.5 | 2.1~3.1 | 0.05~0.25 | 7.2~8.4 | --- | the rest part |

| 7072 | 0.35 | 0.4 | 0.2 | 0.05~0.5 | 1~1.4 | 0.1~0.35 | 4~5 | --- | the rest part |

| 7175 | 0.15 | 0.2 | 1.2~2.0 | 0.1 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.1 | the rest part |

| 7178 | 0.4 | 0.5 | 0.6~2.4 | 0.3 | 2.4~3.1 | 0.18~0.28 | 6.3~7.3 | 0.2 | the rest part |

| 7475 | 0.1 | 0.12 | 1.2~1.9 | 0.06 | 1.9~2.6 | 0.18~0.25 | 5.2~6.2 | 0.06 | the rest part |

Links:https://www.globefindpro.com/products/35752.html

-

Express Post Envelope Making Machine, ZF380

Express Post Envelope Making Machine, ZF380

-

Multi-color Automatic Rotating Screen Printing Machine, WPKY

Multi-color Automatic Rotating Screen Printing Machine, WPKY

-

Aluminum Tube

Aluminum Tube

-

Aluminum Plate

Aluminum Plate

-

Aluminum Tube

Aluminum Tube

-

UV Curing Machine, WPF-UV700

UV Curing Machine, WPF-UV700

-

Vertical Screen Printing Machine, WPKH

Vertical Screen Printing Machine, WPKH

-

Auto Envelope Flap Gluing Machine TJ380

Auto Envelope Flap Gluing Machine TJ380

-

Pneumatic Pad Printing Machine

Pneumatic Pad Printing Machine

-

Reel Type Silk Screen Printing Machine, WQ-320

Reel Type Silk Screen Printing Machine, WQ-320

-

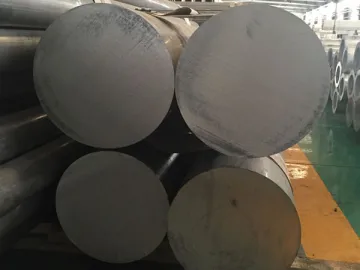

Aluminum Rod

Aluminum Rod

-

Aluminum Plate

Aluminum Plate