MIG/MMA Welding Machine / Inverter Welder

MIG 350GF (Ⅱ) Features IGBT inverter technology, providing high welding reliability and better arc stability; Improved welding process for better welding effect with minimum of weld spatter; Improved design of output interface, 7-pin control plug; Welding wire sizes of 1.0/1.2mm are recommended; Applicable to welding operations with solid wire and flux-cored wire of different diameters; Voltage / current presetting and actual welding parameters displaying, easy to operate; Current, voltage and arc characteristics are adjustable, with 2T/4T setting; Easy to carry, suitable for installation and fabrication applications requiring welding operation; Specifications

Package Included

MIG welding torch, 1pc

Gas hose, 1pc

Wire feeder, 1 unit

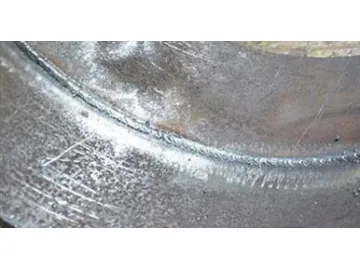

Applications

Optional Welding Accessories

Welding contact tip, 2pcs Welding contact tip, 2pcs Nozzle shield cup Auto-darkening welding helmet Welding gloves ER50-6 MIG solid welding wire

| Model | MIG 350GF(Ⅱ) | |

| Processes | MIG | MMA |

| Input voltage | 3P/380V±15% | 3P/380V±15% |

| Frequency | 50/60Hz | |

| Rated input current (A) | 21 | 23 |

| Output current adjusting range (A) | 60-350 | 40-350 |

| Output voltage (V) | 17-31.5 | 21.6-34 |

| No-load voltage (V) | 60V | 60V |

| Duty cycle (%) | 40 | 35 |

| Power factor | 0.90 | |

| Efficiency | 85% | |

| Type of wire feeder | External | |

| Wire feeding speed (m/min) | 2-16 | |

| Post-flow time (S) | 1.0±0.5 | |

| Welding wire diameter (mm) | 0.8/1.0/1.2 | |

| Insulation class | Class H | |

| Protection grade | IP21 | |

| Welding thickness (mm) | ≥0.8 | |

| Net weight (kg) | 22 | |

| Dimensions (L×W×H) | 508×244×423 mm | |

Package Included

MIG welding torch, 1pc

Gas hose, 1pc

Wire feeder, 1 unit

Applications

Optional Welding Accessories

Welding contact tip, 2pcs Welding contact tip, 2pcs Nozzle shield cup Auto-darkening welding helmet Welding gloves ER50-6 MIG solid welding wire

Scan QR to Read

Links:https://www.globefindpro.com/products/3600.html

Links:https://www.globefindpro.com/products/3600.html

Recommended Products

-

AC/DC TIG/MMA Welding Machine / Inverter Welder

AC/DC TIG/MMA Welding Machine / Inverter Welder

-

MIG/MMA Welding Machine / Inverter Welding Machine

MIG/MMA Welding Machine / Inverter Welding Machine

-

ARC MMA Welding Machine / Stick Welder

ARC MMA Welding Machine / Stick Welder

-

ARC MMA Welder / Inverter Welding Machine

ARC MMA Welder / Inverter Welding Machine

-

MIG/MMA Welding Machine / Inverter Welder

MIG/MMA Welding Machine / Inverter Welder

-

MIG/MMA Welder / Inverter Welder

MIG/MMA Welder / Inverter Welder

-

MIG/MMA Welder / Inverter Welding Machine

MIG/MMA Welder / Inverter Welding Machine

-

ARC MMA Welder / IGBT Inverter Welder

ARC MMA Welder / IGBT Inverter Welder

-

TIG Welding Machine / Inverter Welder

TIG Welding Machine / Inverter Welder

-

ARC MMA Welder / IGBT Inverter Welding Machine

ARC MMA Welder / IGBT Inverter Welding Machine

-

AC/DC TIG/MMA Welding Machine

AC/DC TIG/MMA Welding Machine

-

MIG/MMA Welder / Inverter Welding Machine

MIG/MMA Welder / Inverter Welding Machine

Hot Products