MIG/MMA Welding Machine / Inverter Welding Machine

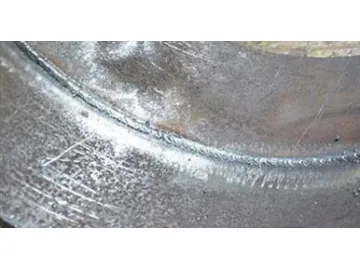

MIG 250GF Features Can achieve CO2 gas shielded MIG welding and MMA welding; Using 0.8mm welding wire for thin sheet metal spot welding with superior performance, resulting in good welding seam formation; Current and voltage are shown via digital display, and able to preset MIG wire feeding speed; Front panel allows for easy adjustment of current, voltage and arc characteristics, as well as 2T/4T setting; Sufficient output of welding current, providing high duty cycle; Waveform control in short-circuit transfer process, ensuring high welding stability and less spatter; Specifications

Package Included

Wire feeder, 1 unit

P180 MIG welding torch, 1pc Welding cable quick connector, 1pc 3m gas hose, 1pc Applications

Optional Welding Accessories

Welding contact tip, 2pcs Welding contact tip, 2pcs Nozzle shield cup Auto-darkening welding helmet Welding gloves ER50-6 MIG solid welding wire

| Model | MIG 250GF | |

| Processes | MIG | MMA |

| Input voltage | 3P/380V±15% | 3P/380V±15% |

| Frequency | 50/60Hz | |

| Rated input current (A) | 14 | 14 |

| Output current adjusting range (A) | 40-250 | 60-250 |

| Output voltage (V) | 16-26.5 | 22.4-30 |

| No-load voltage (V) | 56V | 56V |

| Duty cycle (%) | 30 | 30 |

| Power factor | 0.93 | |

| Efficiency | 85% | |

| Type of wire feeder | External | |

| No-load loss (W) | 120 | |

| Wire feeding speed (m/min) | 3-13 | |

| Post-flow time (S) | 1.0±0.5 | |

| Welding wire diameter (mm) | 0.8/1.0 | |

| Insulation class | Class F | |

| Protection grade | IP21 | |

| Welding thickness (mm) | ≥0.8 | |

| Net weight (kg) | 16 | |

| Dimensions (L×W×H) (mm) | 466×212×371 | |

Package Included

Wire feeder, 1 unit

P180 MIG welding torch, 1pc Welding cable quick connector, 1pc 3m gas hose, 1pc Applications

Optional Welding Accessories

Welding contact tip, 2pcs Welding contact tip, 2pcs Nozzle shield cup Auto-darkening welding helmet Welding gloves ER50-6 MIG solid welding wire

Scan QR to Read

Links:https://www.globefindpro.com/products/3602.html

Links:https://www.globefindpro.com/products/3602.html

Recommended Products

-

ARC MMA Welding Machine / Stick Welder

ARC MMA Welding Machine / Stick Welder

-

ARC MMA Welder / Inverter Welding Machine

ARC MMA Welder / Inverter Welding Machine

-

MIG/MMA Welding Machine / Inverter Welder

MIG/MMA Welding Machine / Inverter Welder

-

MIG/MMA Welder / Inverter Welder

MIG/MMA Welder / Inverter Welder

-

TIG/MMA Welding Machine / Inverter Welder

TIG/MMA Welding Machine / Inverter Welder

-

Window Systems

Window Systems

-

AC/DC TIG/MMA Welding Machine / Inverter Welder

AC/DC TIG/MMA Welding Machine / Inverter Welder

-

MIG/MMA Welding Machine / Inverter Welder

MIG/MMA Welding Machine / Inverter Welder

-

MIG/MMA Welder / Inverter Welding Machine

MIG/MMA Welder / Inverter Welding Machine

-

ARC MMA Welder / IGBT Inverter Welder

ARC MMA Welder / IGBT Inverter Welder

-

TIG Welding Machine / Inverter Welder

TIG Welding Machine / Inverter Welder

-

ARC MMA Welder / IGBT Inverter Welding Machine

ARC MMA Welder / IGBT Inverter Welding Machine

Hot Products