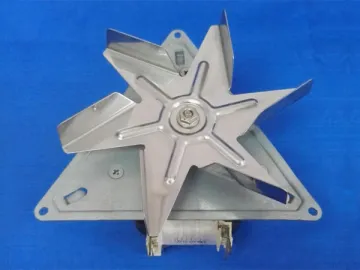

Shaded Pole Motor YJF7221

Distinguished Features of Shaded Pole Motor

1. The shaded pole motor is extremely appropriate for use in 100-240V/50-60Hz kitchen appliances, due to its silent working and stable performance.

2. Outfitted with famous brand fuse protector, temperature controller and enameled copper wires, this electric motor realizes noiseless operation, 5,000 hours service life and excellent temperature protection.

3. The useful blower guarantees low consumption and large airflow.

4. Compliant with CCC and CE standards, the kitchen appliance motor is well known for high energy conversion efficiency.

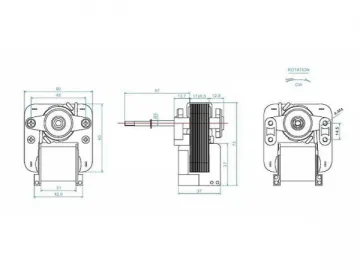

5. Tailor-made shaded pole motor is accessible. The customization specifications include: L × W × H: 72× 75.5× (10-50) mm, shaft dia.: Ф5-6mm, rated power: 30-100W, rated speed: 2,500-3,500rpm.

6. Precise machines have been purchased to run series of tests on raw materials, including coordinate measuring instrument, image measuring device, flame retardant tester, etc.

7. High automation is realized by using many automatic processing machines, such as automatic insert ing machine, automatic winder, welder, to name a few.

8. As for final inspection, dynamometer, noise testing chamber, air flow testing system, consistent temperature chamber, etc.

Materials & Main Parts of Shaded Pole Motor

1. High standard steel is used as raw material.

2. The cast aluminum endplate is firm, strong and difficult to deform.

3. Made using top quality stainless steel, the shaft is consistent to rust and enjoys high strength and rigidity.

4. Stable performance and long working hours are realized by the enameled copper wires.

5. Nylon 66 is used for its UL94-V0 retardant level.

6. The fuse protector is from AUPO, SET and other famous companies.

7. This type of shaded pole motor is well known for ultra-silent operation.

Technical Parameters of Shaded Pole Motor

| Model | Voltage (VAC) | Frequency (Hz) | Air flow (m3/h) | Rated current (A) | Rated power (W) | Rated speed (rpm) | Rotation (CW/CCW) |

| TL7221 | 230 | 50 | 0.47 | 34 | 2950 | CW/CCW |

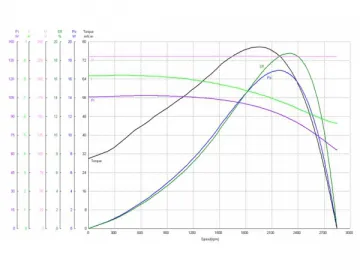

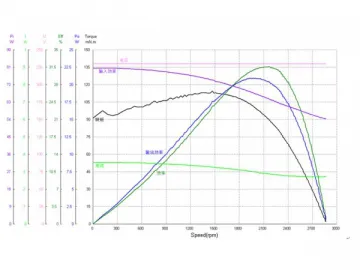

| TL7221 | U | I | Pi | Torque | Speed | Po | Pi-Po | Eff | P.F | Freq |

| V | A | W | mN.m | rpm | W | W | % | Hz | ||

| No load | 229.94 | 0.44 | 31.877 | 1.523 | 2930.24 | 0.467 | 31.41 | 1.47 | 0.315 | 50 |

| Point of peak efficiency | 229.94 | 0.51 | 51.51 | 62.575 | 2477.35 | 16.234 | 35.276 | 31.52 | 0.439 | 50 |

| Point of max. output power | 229.94 | 0.524 | 53.56 | 65.911 | 2385.17 | 16.463 | 37.097 | 30.74 | 0.444 | 50 |

| Point of max. torque | 229.94 | 0.536 | 54.968 | 67.403 | 2301.31 | 16.244 | 38.724 | 29.55 | 0.446 | 50 |

| Point of locked rotor torque | 229.94 | 0.625 | 56.938 | 19.453 | 0 | 0 | 56.938 | 0 | 0.396 | 50 |

The motor can be designed with different structure and components.

Triangle endplate cast aluminum fan blades

Triangle endplate stainless steel fan blades

Triangle endplate cross plate stainless steel fan blades

Links:https://www.globefindpro.com/products/36145.html

-

Capacitor Motor YY8820E

Capacitor Motor YY8820E

-

Shaded Pole Motor YJF6825

Shaded Pole Motor YJF6825

-

Multifunction Horizontal Packaging Machine

Multifunction Horizontal Packaging Machine

-

All-Servo System Packaging Machine, Flow Type

All-Servo System Packaging Machine, Flow Type

-

Rotary Cup Filling and Sealing Machine for Dual Cups

Rotary Cup Filling and Sealing Machine for Dual Cups

-

Capacitor Motor YY5930

Capacitor Motor YY5930

-

Horizontal Form Fill and Seal Machine for Plastic Cups

Horizontal Form Fill and Seal Machine for Plastic Cups

-

Shaded Pole Motor YJF6016

Shaded Pole Motor YJF6016

-

Centrifugal Fan 8040

Centrifugal Fan 8040

-

Spout Pouch Filling and Capping Machine

Spout Pouch Filling and Capping Machine

-

Shaded Pole Motor TL8219

Shaded Pole Motor TL8219

-

Vegetable Packaging Machine

Vegetable Packaging Machine