Cone Mill, ZLZ Series

The ZLZ series cone mill is a portable system used for crushing, screening and reducing the large solids into small uniform particles. It is mainly used in manufacturing solid dosage forms in the pharmaceutical industry.

| Model | ZLZ200 | ZLZ250 | ZLZ300 |

| Production capacity (kg/h) | 200 | 500 | 1000 |

| Rotor speed (r/min) | 150-1500 | 150-1500 | 150-1500 |

| Rotor motor power (kW) | 2.2 | 4 | 5.5 |

| Screen mesh (mesh) | 5-30 | 5-30 | 5-30 |

| Weight (kg) | 300 | 400 | 550 |

Scan QR to Read

Links:https://www.globefindpro.com/products/3670.html

Links:https://www.globefindpro.com/products/3670.html

Recommended Products

-

Wrap-around Labeling Machine, LM-W01

Wrap-around Labeling Machine, LM-W01

-

Medical High Purity Nitrogen Generator

Medical High Purity Nitrogen Generator

-

IBC Bin for Mixing, HLDF Series

IBC Bin for Mixing, HLDF Series

-

Induction Cap Sealing Machine, CSI-200

Induction Cap Sealing Machine, CSI-200

-

Stick Packing and Arranging Machine, SP-S12 Series

Stick Packing and Arranging Machine, SP-S12 Series

-

Automatic Bin Blender, DHZ Series

Automatic Bin Blender, DHZ Series

-

Laboratory Bin Blender, DHS Series

Laboratory Bin Blender, DHS Series

-

Laboratory Fluid Bed Dryer, TVP Series

Laboratory Fluid Bed Dryer, TVP Series

-

Multifunction Fluid Bed Dryer, TVP Series

Multifunction Fluid Bed Dryer, TVP Series

-

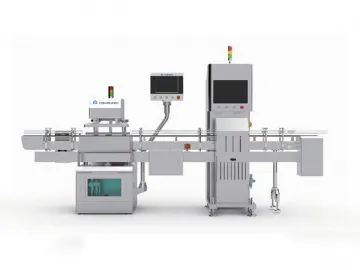

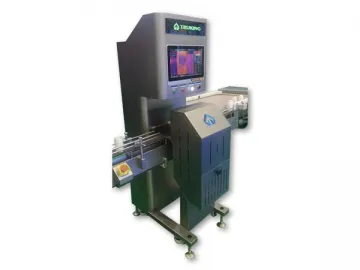

Seal Inspection Machine, CSV-200

Seal Inspection Machine, CSV-200

-

Roller Compactor (for Dry Granulation), LGP200-75

Roller Compactor (for Dry Granulation), LGP200-75

-

GH019-HA Semi-automatic 6 inch Sewing Thread Winding Machine

GH019-HA Semi-automatic 6 inch Sewing Thread Winding Machine