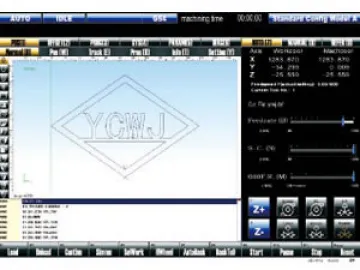

Water Jet Controller

The YC-NC9000A water jet controller is particularly developed based on our years of experience in the industry. As a new generation of waterjet control system, our product has the following features.

1. It supports a variety of codes like G, PLT, ENG, and DXF generated by CAD/CAM software like UG, MASTERCAM, AUTOCAD, and some others.

2. The function of breakpoint memory and blocked program jumping are also available with this waterjet controlling device.

3. Auto deceleration and suspension for small bore, arc, and corner.

4. Cutting figure real-time simulation.

5. It supports processing time prediction, process path pre-loading and dynamic tracking display.

In addition, we also have Italian ECS-905 controller suitable for cutting all sheet materials. It offers oxygen cutting, plasma arc, waterjet cutting, laser cutting and drilling, and so on. The operation of the product can be controlled by 16 axes. The 5-axis cutting torch control and the IPC, as well as the AMD hardware structure, make for the high performance but low power consumption of the CNC waterjet controller.

Configurations

Monitor: 15" LCD, integrated touch screen

Peripheral interface: EtherCAT

Node: EtherCAT controlled EcsLink, Mechatrolink®1 and 2, Sercos ®1, Profinet ®1, and analogic drives

Up to 2048 I/O with EtherCAT

Modular mechanical panel: optional

Keyboard: optional

FastCAM Standard Software Introduction

As a nationally famous brand in welding industry, FastCAM has been engaged in the industry for over 30 years. The FastCAM software is a kind of dedicated programming software suitable for the cutting machine of NC flame series, plasma series, laser series and waterjet series. Requiring little knowledge related to computer technology and CAD, the plotting, nesting and programming is quite easy to understand.

Currently, FastCAM is providing multilingual technical support & training on software, and promoting and sharing NC cutting theory and technology. On the premise of improving steel utilization ratio, FastCAM effectively enhances the cutting quality and cutting efficiency.

Technical Parameters of High Pressure System

Control: PLC

Reversing Mode: electro-hydraulic control

Cooling Mode: water cooled (plate type oil-water heat exchanger)

Inlet Water Filter fineness: ≤0.45μm

Oil-return Filter Fineness: 20μm

Working Temperature: 0-60°C

Outlet Connection: UNF 3/8"

Cooling Inlet and Outlet: NPT1"

Max. Orifice Size: 0.33mm

Related Names

Waterjet Control System | CNC Waterjet Machine | Waterjet Software | Waterjet Program | Waterjet Cutting Machine | CNC Controlling System

Links:https://www.globefindpro.com/products/37230.html

-

Cantilever/ Fly-arm Water jet Cutting Table X1313

Cantilever/ Fly-arm Water jet Cutting Table X1313

-

Water Jet High Pressure System YCG3038

Water Jet High Pressure System YCG3038

-

CNC Flame/Plasma Cutting Controller

CNC Flame/Plasma Cutting Controller

-

Whirlwind Air Classifier

Whirlwind Air Classifier

-

LHS Dry Particle composing Machine (Powder fusion,surface modification)

LHS Dry Particle composing Machine (Powder fusion,surface modification)

-

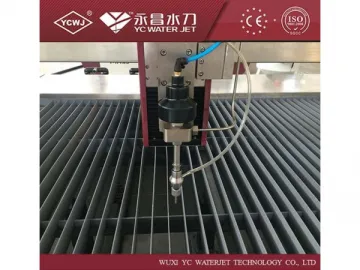

Full Set Water Jet Cutting Machine

Full Set Water Jet Cutting Machine

-

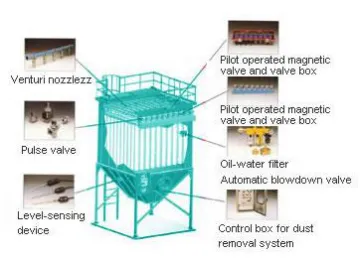

Pulse Bag-type Collector

Pulse Bag-type Collector

-

Coating Machine

Coating Machine

-

Gantry/ Bridge Water Jet Cutting Table L4030

Gantry/ Bridge Water Jet Cutting Table L4030

-

Self-diffluent Classifier

Self-diffluent Classifier

-

Cantilever/ Fly-arm Water Jet Cutting Table X1520

Cantilever/ Fly-arm Water Jet Cutting Table X1520

-

Plasma Cutting System

Plasma Cutting System