8m³, 13m³ Asphalt Distributor (Automatic Type)

Brief Introduction of the Automatic Asphalt Distributor

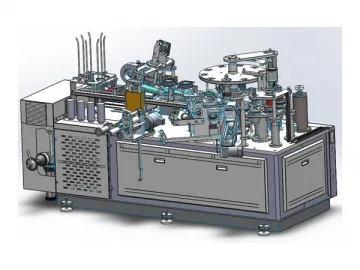

The 8-cubic meter automatic asphalt distributor is a hi-tech machinery specialized in spraying emulsified, diluted, hot, heavy-duty and high viscous modified asphalts. Its highly engineered design guarantees the uniform spraying of asphalt. Industrial computer control is stable and reliable. The design of this distributor has been improved and perfected for road construction by our expert engineers.

This product is used in a wide variety of highway construction and road maintenance projects. It is used to apply upper and lower seal coats, prime layers, waterproof layers, adhesive layers and asphalt surfacing.

Components and Structures of the Automatic Asphalt Distributor

The HGY5161GLQ automatic asphalt distributor’s main components consist of a tractor unit, asphalt spray system, air circuit system, water circuit system, speed measuring system and a power supply system.

Tractor

The asphalt truck is constructed with a Sinotruck HOWO, which features a large bearing capacity, low fuel consumption, easy operation and a reliable breaking system.

Heat Oil System

1.The coil realizes heat oil circulation from the heat oil furnace inlet and outlets through the heat oil pipeline to heat the asphalt in the tank and pipeline.

2.The hot oil pump forces the heated oil through the system.

3.A fire tube boiler is the heat source used to raise and maintain the temperature of the oil in circulation.

4.An expansion tank supplies space for fluid expansion to take place when oil is heated. Water and air from heated oil are separated and eliminated through this tank. The air hole in this tank bridges the heat oil system and external space to make a safe and low-cost atmospheric system.

5.An imported diesel dual burner is installed to heat the HTF interlayer of the tank fire tube. All the nozzles and asphalt pipes are heated by HTF cycles to ensure the smooth cycle of asphalt. High heating efficiency and short preheating standby time reduce the auxiliary time of construction.

Spray System

The spray system is made up of the asphalt tank, asphalt pipeline, asphalt pump, asphalt filter, spray unit and nozzle carrier lifting device.

1.The asphalt tank has an insulation layer with thickness of 100mm to preserve the temperature of heated asphalt, improving heating efficiency and reducing auxiliary construction time to maintain appropriate spray temperature.

2.The asphalt pipeline is used to deliver asphalt to the nozzle shell or start major and minor cycles: asphalt tank – pipeline – asphalt pump – pipeline – asphalt tank.

3.The asphalt pump is a power unit that pumps asphalt through the pipeline of the system.

4.An asphalt filter element is equipped to remove foreign matter from the asphalt, protecting the pump.

5.The spray unit of the automatic asphalt distributor has a fast acting piston that completes the turning on/off of the nozzles by means of its straight reciprocating motion. Each nozzle is controlled by a pressurized cylinder.

6.The nozzle carrier lifting device has two lifting cylinder to control nozzle carrier height.

Air Circuit System

The air circuit system of this automatic asphalt distributor is powered by the tractor unit which provides the air supply. The system consists of the air supply, distribution air bags, control valve, air tube, solenoid valve, and cylinder. The tractor unit provides a steady supply of air which leads to consistent operation of the power system, chip spreader, asphalt spray and asphalt valve group and waterway system.

Water Circuit System

The water circuit system is composed of a water tank, filter, solenoid valve, control valve, water pipe, water spray frame, and water nozzle. The water nozzles are installed on the upper part of each tire, which effectively prevents asphalt adhesion on the tires during operation.

Control System

1.Automatic control of the spray volume and walking speed according to the spray capacity.

2.Spray volume can be changed via computer in the cab, the procedure can automatically adjust itself.

3.The accurate control of the asphalt pump displacement makes the spray volume error ±1.5%.

4.Easy switch between manual and automatic modes.

5.The asphalt and chips spray width can be easily adjusted.

6.The automatic asphalt distributor can be controlled in cab or at the back operating platform of the equipment.

Speed Measuring System

The speed measuring system primarily consists of a power supply, radar detector, signal conversion device and an output device. This particular model uses a 12V DC inverter power supply to prevent any electrical system overload.

The system has advantages of an outstanding anti-interference capability, water resistance, and shock resistance.

Power Supply System

The power takeoff has key parts (hydraulic pump, hydraulic motor, lifting hydraulic cylinder, asphalt pump, heat oil pump, gas control valve, proportioning valve, automatic control system, velocity radar, etc.) that are all qualified to guarantee the reliability of the automatic asphalt distributor and prolong the service life.

Advantages of the Automatic Asphalt Distributor

1.This road construction equipment reduces the construction labor intensity, budget constraints, and resources, and it improves work efficiency and quality.

2.The automatic asphalt distributor gets its force from the tractor power.

3.Excellent insulation, anticorrosion abilities and durability.

4.This equipment uses the high precision nozzles to ensure spray consistency.

5.The equipment operation can be controlled remotely but also has onboard controls.

Key Components of the Automatic Asphalt Distributor

| No. | Name | Brand | Place of origin | Remarks |

| 1 | Chassis | SINOTRUK HOWO | China | National emissions standard stage four |

| 2 | Asphalt tank | Shenggong | China | 100mm insulating layer |

| 3 | Steel flange globe valve | Beifang | China | |

| 4 | Asphalt valve group | Shenggong | China | |

| 5 | Touch screen | MCGS | China | |

| 6 | Asphalt Pump | Vikin or Johnson | USA/Belgium | |

| 7 | Heat oil pump | Vikin or JOHNSON | USA/Belgium | |

| 8 | Asphalt pump motor | iNi | China | |

| 9 | Heat oil pump motor | SAUER DANFOSS | Demark | |

| 10 | Burner | Beckett | Italy | 24VDC |

| 11 | speed measuring radar | DICkEY-john | USA | |

| 12 | PLC control system | IDEC | Japan | |

| 13 | Hydraulic servo pump | SAUER DANFOSS | USA | |

| 14 | Sealing elements | DICHTOMATIK | Germany | |

| 15 | Throttle valve | Parker | Germany | |

| 16 | Transducer | Koyo | China | |

| 17 | Cylinder | Fsh | China | |

| 18 | Air control assembly valve | JPC | China | |

| 19 | Air treatment components | AIRTAC | Taiwan |

8m³ HGY5161GLQ Automatic Asphalt Distributor Main technical parameters

| Product Model | HGY5161GLQ |

| Chassis model | ZZ1167M4617D1 |

| Spray width | 200-6000mm |

| Spray volume | 0.2-3.0 kg/m2 |

| Asphalt tank volume | 8000L |

| Asphalt heating mode | Imported diesel oil burner (calorific value 10×104kCal/h) |

| Spray media | hot (modified) asphalt, diluted asphalt, emulsified asphalt, etc. |

| Spray precision | ±1.5% |

| Total weight | 16000kg |

| Overall dimensions | L×W×H=8830×2496×3420(mm) |

13m³ HGY5255GLQAutomatic Asphalt Distributor Main technical parameters

| Product Model | HGY5255GLQ |

| Chassis model | ZZ1257M4647D1 |

| Spray width | 200-6000mm |

| Spray volume | 0.2-3.0 kg/m2 |

| Asphalt tank volume | 13000L |

| Asphalt heating mode | Imported diesel oil burner (calorific value 10×104kCal/h) |

| Spray media | hot (modified) asphalt, diluted asphalt, emulsified asphalt, etc. |

| Spray precision | ±1.5% |

| Total weight | 25000kg |

| Overall dimensions | L×W×H=10735×2496×3820(mm) |

Links:https://www.globefindpro.com/products/37731.html

-

Intelligent Slurry Seal (Micro Surfacing Paver)

Intelligent Slurry Seal (Micro Surfacing Paver)

-

Paper Cup Making Machine DESPU-D16

Paper Cup Making Machine DESPU-D16

-

HGY5314TFC Synchronous Chip Sealer

HGY5314TFC Synchronous Chip Sealer

-

DEBAO-600S-SY Paper Cup Making Machine

DEBAO-600S-SY Paper Cup Making Machine

-

GYRY10A Asphalt Emulsion Plant

GYRY10A Asphalt Emulsion Plant

-

Paper Cup Making Machine DESPU-C22

Paper Cup Making Machine DESPU-C22

-

Semi-automatic Asphalt Distributor

Semi-automatic Asphalt Distributor

-

Asphalt Pavement Slotting Machine

Asphalt Pavement Slotting Machine

-

T40/16 Self-drilling Rock Bolt and Accessories

T40/16 Self-drilling Rock Bolt and Accessories

-

Rock Splitting Wedges

Rock Splitting Wedges

-

T76S Self-drilling Rock Bolt and Accessories

T76S Self-drilling Rock Bolt and Accessories

-

Thread R32

Thread R32