Intelligent Slurry Seal (Micro Surfacing Paver)

Gaoyuan Company is a China-based micro surfacing paver manufacturer, which is dedicated to providing global customers with the best intelligent slurry seal solutions. Our intelligent slurry paver is a patented road maintenance machine that is developed on the basis of the internationally advanced technologies. In order to offer customers better quality products, we purchase key components from renowned suppliers, like Sino Truck low speed chassis ZZ1256, Germany BUCHER hydraulic valve, Italy ITALVIBRAS vibrating motor.

Application

CE and CCC certified, the micro surfacing paver treats pavement when its friction resistance is reduced, there are cracks and ruts in the road, or it needs to be waterproofed. Whether slurry sealing, modified sealing, or micro-surfacing, the intelligent slurry seal machine repairs and makes roads even and smooth for comfortable traveling and safe driving. Our patented slurry paver is developed using internationally advanced technology and has been tested and improved for a variety of construction projects.

Spread Tank for Slurry Paver

Adjustable Biaxial Rectangular Spread

Tank (Spreading Width: 2.5~4.3m)

V-shaped Spread Tank for Ruts Repair

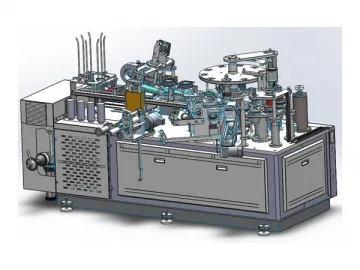

HGY5251TFC Intelligent Slurry Paver (Intelligent Micro Surfacing Paver)

Main Technical Specifications

| Product Model | HGY5251TFC |

| Chassis Model | ZZ1257M4347D1 |

| Emission Standard | National Emission Standard Stage Four |

| Auxiliary Engine Power | 70kw/2400rpm |

| Aggregates Bin Volume | 10m3 |

| Emulsion Tank Volume | 3.5 m3 |

| Water Tank Volume | 3.5 m3 |

| Additive Tank Volume | 400L |

| Filler Tank Volume | 2×0.5 m3 |

| Max. Discharging Volume of Mixer | 3.5T/min |

| Min. Vehicle Speed | 1 km/h |

| Paving Depth | 3 ~ 15 mm |

| Width of Spreading Tank | 2.5 ~ 4.3 m , adjustable width |

| Overall Dimensions | 10860×2496×3360 mm (L×W×H) |

| Chassis | Specially costumed low speed chassis ZZ1257M4347D1 made by SinoTruk |

| Auxiliary Engine | China YUCHAI 70kw/2400rpm |

| Hydraulic Pump | China PERMCO |

| Asphalt Pump | China HENGXING |

| Hydraulic Valve | Taiwan NORTHMAN |

| Hydraulic Motor | Denmark DANFOSS |

| Vibrating Motor | Italy ITALVIBRAS |

| Reduction Gear | China GUOMAO |

| Main Electric Unit | Taiwan DELTA |

| Text Display | China ACEPILLAR |

| Electric Relay | Germany WEIDMULLER; Japan IDEC |

| Mixer | China SG, Forced double-shaft mixer |

| Spread Box | China SG: GYJT2543 |

HGY5311TFC Intelligent Micro Surfacing Paver

Main Technical Parameters

| Product Model | HGY5311TFC |

| Chassis model | ZZ1317M3867D1 |

| Emission Standard | National emission standard stage four |

| Engine Power | 110kw/2300rpm |

| Aggregates Bin Volume | 12 m3 |

| Emulsion Tank Volume | 4 m3 |

| Water Tank Volume | 4 m3 |

| Additive Tank Volume | 600 L |

| Filler Tank Volume | 2 × 0.5 m3 |

| Discharging Volume of Mixer | max.3.5T/min |

| Minimum Vehicle Speed | 1 km/h |

| Width of Paver | 2.5-4.3 m |

| Overall Dimensions | 11690 × 2496 × 3490 (mm) (L × W × H) |

Key Components of the Intelligent Slurry Seal Machine

| Chassis | SinoTruk ZZ1317M3867D1 |

| Auxiliary Engine | Cummins |

| Asphalt Pump | China Hengxing |

| Hydraulic Pump | USA PARKER |

| Hydraulic Valve | Germany BUCHER |

| Hydraulic Motor | Denmark DANFOSS |

| Hydraulic Reversing Valve | Germany ARGO-HYTOS |

| Vibrating Motor | Italy ITALVIBRAS |

| Reduction Gear | Tianjin SEW |

| Main Electric Unit | Japan OMRON |

| Text Display | Japan OMRON |

| Electric Relay | Germany WEIDMULLER/Japan IDEC |

| Mixer | China SG: Forced double-shaft mixer |

| Paving Box | China SG GYJT2543 |

If you are in need of an asphalt distributor, cold slurry patcher or synchronous chip sealer, we at Gaoyuan can also help you with your needs. As our products are reliable, durable and economical, they are highly sought after by customers from Poland, Russia, Indonesia, Vietnam, Kazakhstan, Kyrgyzstan, Nigeria, Angola, Congo, among other countries.

Thank you for visiting our website. We are certain that you will be satisfied with our road maintenance equipment.

Components & Structures of the Intelligent Slurry Seal Machine (Micro Surfacing Paver)

1. Fillers feeding subsystem

2. Emulsion feeding subsystem

3. Water supply subsystem

4. Aggregates feeding subsystem

5. Additive feeding subsystem

1. Chassis

The chassis is a special 6x4 chassis from SinoTruk Howo that has good mobility, a maximum load of 25t and a 198 hp engine. The chassis meets Euro III Emissions Regulations and has a two-speed gearbox that lets the truck stay in high gear during transportation and low gear during construction. The truck has a minimum speed of 1 km/h for efficient paving.

2. Feeding System

The materials feeding system for the intelligent slurry seal machine consists of an aggregate feeding subsystem, emulsion feeding subsystem, water supply subsystem, fillers feeding subsystem and additive feeding subsystem.

Aggregate feeding subsystem

This subsystem consists of an aggregate bin, stilling cone, feed gate, belt conveyor, drive system and feeding shortage alarm device.

1. Aggregate bin with volume of 10m3 has a vibrating stilling cone which prevents the bin from sliding if the belt has too much weight and improves the conveyor’s stability.

2. Feed gate and independent belt conveyor is easy to assemble, disassemble and adjust for different projects.

3. Strong hydraulic motor accompanied by reduction gear conveys stably. Infinite variable control mode and advanced velocity-measuring feedback sensors allow for accurate operations.

4. Feeding shortage alarm device monitors the conveying of aggregate to ensure quality control during construction.

Emulsion feeding subsystem

This subsystem for our intelligent slurry seal machine contains an emulsion tank, emulsion pump, proportional solenoid valve, control valve, pipeline and drive system.

1. Emulsion tank has a volume of 3.5m³.

2. Emulsion pump has a rotor positive-displacement pump that has an efficient and steady flow rate. Advanced velocity sensor gives an accurate emulsion supply volume. The jacket heating pump allows it to be used in severe working conditions. The pump also pumps oil by itself for convenient fueling during construction.

3. The automatic air control valve is from well-known international brands.

4. The strong hydraulic motor, also from well-known international brands, drives stable conveying. Infinite variable control allows for accurate control and operations.

Water supply subsystem

This system contains a water tank, water pump, flow meter, control valve, pipeline and power drive system.

1. Water tank has a volume of 3.5m³.

2. A centrifugal water pump is stable and long lasting. A glass rotameter allows for direct and convenient operation.

3. Air control valve of good quality offers automatic control.

4. Double water recharging devices monitor and prepare the slurry mixture.

5. High pressure washing device regularly cleans and maintains the intelligent slurry seal machine.

6. Watering device meets requirements of various construction technologies.

Fillers feeding subsystem

This system stores and feeds two types of fillers depending on the construction project. An internal fluffer and spiral feeder guarantee a stable and precise discharging volume.

Additives feeding subsystem

All the components and parts of this device are made of stainless steel. The device is driven by air pressure and performs stably. A reliable, easy-to-use glass rotameter reads the flow rate.

3. Mixing System

The mixing system for our intelligent slurry seal machine uses a biaxial spiral blade to mix and convey materials. Featuring a high abrasion blade, the mixing system has a high rotating speed, strong power and thorough mixing. The adjustable rake angle of the mixer lets users adapt to road construction projects of different slopes. The maximum discharging volume is 3.5t/min.

4. Spreading System

The automatic telescopic spreading box can be used on any kind of road and regulates with appropriate camber according to the conditions of the road construction. Double-row spiral propeller spreads and re-tempers to prevent slurry from segregating. The underside of the spreading system is made of hard alloy wearing material for a longer service life and no skidding. A strong hydraulic motor from well-known international brands stably drives the conveyor belt. The rotating speed and direction can be adjusted according to the construction method.

5. Power System

The power system for our intelligent slurry seal machine consists of an engine and hydraulic system. The water-cooled engine has a rating power of 70kw/2400rpm and is equipped with a high-powered, stable, and reliable turbocharger.

The hydraulic system consists of a hydraulic pump, hydraulic motor, and hydraulic control valve made from well-known domestic and international brands. The power unit of this system is controlled by five groups which supply independent power to their respective systems and keeps them free from interference.

6. Control System

Collective control allows the user to operate all the controllers on the operating platform and starts and stops operations with one switch. Specified data of the asphalt to aggregate ratio is entered and the computer automatically processes the ratios. Proportional follow-up control technology measures the emulsified asphalt and aggregate for precise and uniform spreading.

The discharging volume is adjustable according to the traveling speed of the vehicle. Equipped with a PLC, the control system includes alerts and information displays.

Advantages

1. We have patented our intelligent slurry seal machine, developed from similar products.

2. The chassis is equipped with a two-speed gear box so the paver and sealer machine can travel in high gear and finish construction projects in low gear.

3. Key parts are from well-known international brands to guarantee reliability and stability.

4. Asphalt to aggregate ratio is precisely and automatically measured.

5. The discharging volume is adjustable according to the traveling speed during construction.

6. The maximum mixing volume of 3.5t/min fits for different widths, depths and technologies in construction projects.

7. The intelligent slurry sealer features collective control, alerts and display system, and user-friendly operation.

8. Optimized spreading box prolongs the micro surfacing paver’s service life and improves construction quality.

Links:https://www.globefindpro.com/products/37732.html

-

Paper Cup Making Machine DESPU-D16

Paper Cup Making Machine DESPU-D16

-

HGY5314TFC Synchronous Chip Sealer

HGY5314TFC Synchronous Chip Sealer

-

DEBAO-600S-SY Paper Cup Making Machine

DEBAO-600S-SY Paper Cup Making Machine

-

GYRY10A Asphalt Emulsion Plant

GYRY10A Asphalt Emulsion Plant

-

Paper Cup Making Machine DESPU-C22

Paper Cup Making Machine DESPU-C22

-

DEBAO-600C Paper Cup Making Machine

DEBAO-600C Paper Cup Making Machine

-

8m³, 13m³ Asphalt Distributor (Automatic Type)

8m³, 13m³ Asphalt Distributor (Automatic Type)

-

Semi-automatic Asphalt Distributor

Semi-automatic Asphalt Distributor

-

Asphalt Pavement Slotting Machine

Asphalt Pavement Slotting Machine

-

T40/16 Self-drilling Rock Bolt and Accessories

T40/16 Self-drilling Rock Bolt and Accessories

-

Rock Splitting Wedges

Rock Splitting Wedges

-

T76S Self-drilling Rock Bolt and Accessories

T76S Self-drilling Rock Bolt and Accessories