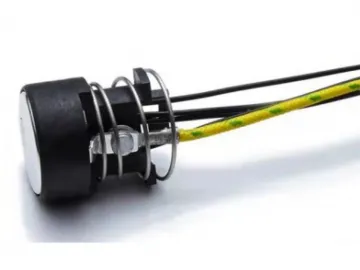

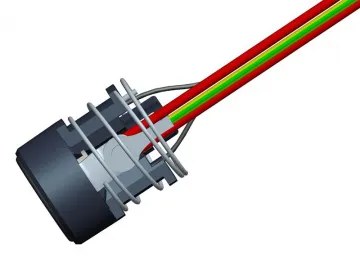

Thin-Film Temperature Sensor, High Temperature Type, MJMA

Among all types of our temperature sensors, the thin film temperature sensor provides the fastest response speed, smallest size, lightest weight and thinnest thickness.

In March 2012, Minjie Electronics set up a research project of MJMA thin-film temperature sensors and in April 2015, this type of high temperature sensor was put into mass production and quickly won high praise from many customers.

Request a QuoteThe successful research of MJMA temperature sensor fills in the gap of thin-film NTC temperature sensor in China and quickly swept the market for its fast response, small size, thin thickness, high reliability, compact structure, concise appearance and bending resistance.

The innovation of the high-temperature thin-film temperature sensor is mainly demonstrated in these following aspects

This NTC temperature sensor abandons traditional electric cable and implements flexible flat cable to increase the bending resistant capacity of products and make sure it can be used in narrow space. Plus, the length of temperature sensing product can be designed upon request. Produced with uniform flexible flat cables, the thin-film sensor overcomes traditional problems like complex structure and low uniformity. The MJMA thin-film temperature sensor provides a wide temperature range (-40 to 260℃), high voltage resistance, small volume, light weight and thin thickness (0.2mm). It's widely used in cellphones, home appliances and aviation. High-degree automatic production of MJMA high temperature sensor is realized thanks to its brilliant design and excellent properties. Therefore, it will inevitably replace traditional temperature sensors. Moreover, because the manufacture process is simplified, the reliability, uniformity, precision and sensitivity are further guaranteed. Differences of Traditional Temperature Sensor and MJMA Thin-Film Temperature Sensor| Items | NTC thermistor | Cable | Cover | Epoxy resin | Sleeving | Terminal | Hole seat |

| Traditional high temperature sensor | Glass-encapsulated Diode, single-end glass encapsulated | PTFE cable, PE cable, silica gel cable, braided wire | Various types | Yes | Yes | Yes | Yes |

| High-temperature thin-film sensor | Single-end glass encapsulated | Flexible flat cable | No | No | No | Yes | Yes |

| Name | Quality control | Properties | Specifications | Production method | Manufacture speed | |||||||

| Welding | Encapsulating | End connecting | Response speed | High voltage resistance | Bending resistance | Reliability | Weight | Thickness | Volume | |||

| Low-temperature thin-film sensor | Need control | Need no control | Need no control | Fast | Good | Good | High | Light | Thin | Small | Fully-automatic | Fast |

| High-temperature thin-film sensor | Need control | Need no control | Need no control | Fast | Good | Good | High | Light | Thin | Small | Fully-automatic | Fast |

| Traditional temperature sensor | Need control | Need control | Need control | Slow | Not bad | Bad | Low | Heavy | Thick | Big | Multi-staged | Slow |

Using the thin-film temperature sensor, the appliance bottom is flat and smooth, easy to clean and water scale free.

For commonly-used sensors, the appliance bottom is drilled with holes to install sensor. The hole surrounding part is difficult is clean and easy to hide water scale.

Technical Parameters of MJMA Thin-Film Temperature Sensor| Temperature range | -40℃ to 260℃ |

| Resistance | 100 kΩ/200kΩ |

| B value | 3688 K |

| Thickness (thin film thermistor ) | 2 mm |

Hot pots, coffee machines, refrigerators, steam stoves and other home appliances.

Matter Needs AttentionThe thin film should be kept smooth without wrinkles. The divergent part of the terminal cannot be longer than the stiffening plate.

Tags: high temperature sensor temperature sensing solution custom thin-film sensorLinks:https://www.globefindpro.com/products/3835.html

-

Surface Temperature Sensor, MJYH

Surface Temperature Sensor, MJYH

-

Magnetic Proximity Sensor, HJL

Magnetic Proximity Sensor, HJL

-

Temperature Sensor, Pot Bottom Type, MJRA

Temperature Sensor, Pot Bottom Type, MJRA

-

Pot Bottom Temperature Sensor, MJRB

Pot Bottom Temperature Sensor, MJRB

-

Pipe Temperature Sensor, MJZP

Pipe Temperature Sensor, MJZP

-

Food Probe Temperature Sensor, MJYA

Food Probe Temperature Sensor, MJYA

-

Temperature Sensor, MJK

Temperature Sensor, MJK

-

Temperature Sensor, Rivet Type, MJZP

Temperature Sensor, Rivet Type, MJZP

-

High Temperature Sensor, MJX

High Temperature Sensor, MJX

-

Super-High Pot Bottom Temperature Sensor

Super-High Pot Bottom Temperature Sensor

-

Temperature Sensor, MJZE

Temperature Sensor, MJZE

-

Temperature Sensor, Rivet Type, Waterproof Type, MJRC

Temperature Sensor, Rivet Type, Waterproof Type, MJRC