Manufacturing Process

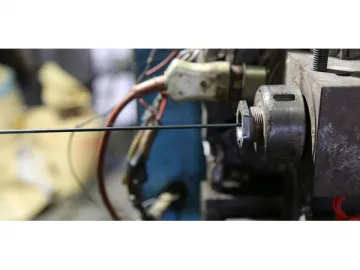

I.The First Process

The insulated wire extruding machine is used to extrude double insulated layer for nuclear cables. This is the first process of cable production.

The control console with touch screen can display all of the cable parameters during the manufacturing process.

On-Line measure and control equipment is used to detect the outer diameter and the concentricity of the cables. The high accuracy enables to control the error between 0~0.02mm.

The circulating water in the 25m-long water channel is controlled at a constant temperature to ensure a uniform cooling effect.

Belt-driven puller can wind cables tightly in a uniform manner.

The cable end winding device can wind 1000m of cable. The winding length is adjustable.

II.The Second Process

The cable forming machine twists 6 wires together with the production capacity of 2000m/hour.

III. The Third Process

The wrapping process can be performed with halogen-free tape, polyester tape or aluminum foil tape. An operator can operate several machines at once.

IV.The Fourth Process

The insulated wire twisting process is to wrap a layer of steel wire to protect and strengthen the cable.

V. The Fifth Process

This is the final process – the extrusion of the cable jacket.

Links:https://www.globefindpro.com/products/38618.html

-

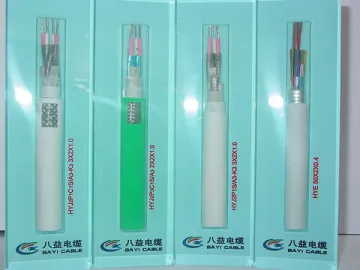

Nuclear Power Plant Instrumentation Cable, Class 1E

Nuclear Power Plant Instrumentation Cable, Class 1E

-

Nuclear Power Plant Compensating Cable, Non-Class 1E

Nuclear Power Plant Compensating Cable, Non-Class 1E

-

Enterprise in Pictures

Enterprise in Pictures

-

Low-Voltage Power Cable

Low-Voltage Power Cable

-

Nuclear Power Plant Insulated Cable, Non-Class 1E

Nuclear Power Plant Insulated Cable, Non-Class 1E

-

Changlin News

Changlin News

-

Double Cylinder Sock Knitting Machine

Double Cylinder Sock Knitting Machine

-

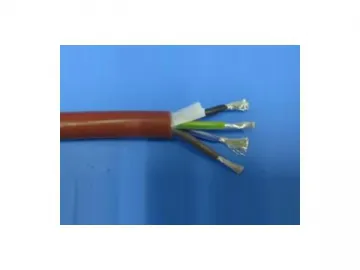

Silicone Rubber Insulated Control Cable

Silicone Rubber Insulated Control Cable

-

Petroleum and Chemical Plant Control Cable

Petroleum and Chemical Plant Control Cable

-

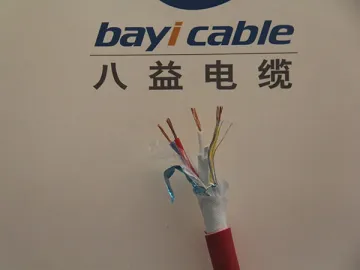

DCS System Fire Resistant Instrumentation Cable

DCS System Fire Resistant Instrumentation Cable

-

Construction Pictures

Construction Pictures

-

Plain Sock Knitting Machine

Plain Sock Knitting Machine