Troubleshooting

1. Cutting Tension Deficiency

Reason one: The diamond blade is so hard comparatively that the steel plate is overstressed.

Solution: Make sure that the materials can fit for the hardness of the diamond cutting blade.

Reason two: During cutting, the materials slide, resulting in blade deformation because of twist or bend.

Solution: Hold tightly the materials when the diamond saw blade is cutting.

Reason three: The rotational speed of the diamond blade is wrong.

Solution: Tachometer should be used to check whether the rotational speed of axes is appropriate. It is significant for concrete cutting tools.

Reason four: The flanges are too small or come with different diameter so that the steel plate is pressed unevenly.

Solution: Make sure that the flanges boast correct and same size.

2. Grinding Segment Crack

Reason one: The diamond saw blade is too hard.

Solution: Please use appropriate blade with more flexible adhesive.

Reason two: Center crack may be resulted from overheating caused by water supply deficiency in wet cutting or improper use of dry cut.

Solution: Sufficient water for cooling the diamond blade should be ensured in wet cutting and adequate air flow around the diamond blade is another promise in dry cutting.

3. Partial Uneven Wear

Reason one: Only one side wear of the diamond saw blade segments will narrow the side clearance. This type of wear is usually caused by improper positioning of the blade or insufficient cooling of two sides.

Solution: To deal with this problem, you should check whether the diamond tool is correctly positioned, and clean cooling equipment so as to make flange front side be appropriately cooled. In addition you should check whether the pump is capable of offering regularly sufficient water.

Reason two: Bad bearing, worn axes, unclean or damaged flanges, and even excessive barriers may result in partial wear of the diamond blade.

Solution: The bearing and worn axes should be replaced as required and the drive pivot pin can not be removed.

Links:https://www.globefindpro.com/products/39071.html

-

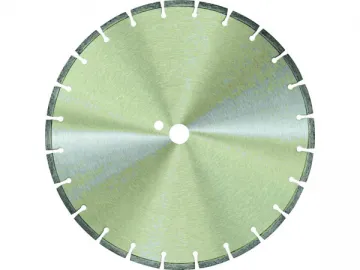

Laser-welded General Purpose Diamond Blade

Laser-welded General Purpose Diamond Blade

-

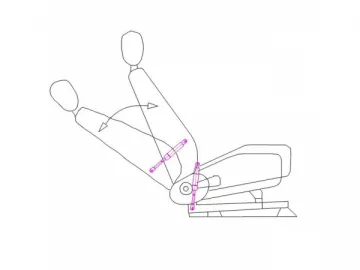

Gas Springs for Office Furniture

Gas Springs for Office Furniture

-

Government Buildings

Government Buildings

-

Gas Springs for Household Furniture

Gas Springs for Household Furniture

-

Sustainable Development

Sustainable Development

-

Other Industrial Gas Spring

Other Industrial Gas Spring

-

Diamond Grinding Tools

Diamond Grinding Tools

-

Roll-fed Block Bottom Paper Bag Machine

Roll-fed Block Bottom Paper Bag Machine

-

Clothing Packaging Paper Carrier Bag Making Machine

Clothing Packaging Paper Carrier Bag Making Machine

-

Tire Recycling Equipment

Tire Recycling Equipment

-

Paper Food Bag Making Machine

Paper Food Bag Making Machine

-

Engine Cooling System

Engine Cooling System