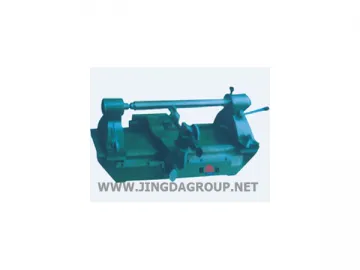

High Precision Bench Center

When connected to the computer, the high precision bench center can more accurately, directly test the relevant data. The application of a pair of Mohs hardness 4# alloy tips together with the gear transmission, has greatly enhanced the measurement precision and increased the weight to support the parts that need testing. Therefore, this bench type testing tool can test the radial, end, or oblique circular runout.

Our horizontal inspection center is convenient to operate. Its dial gauge stand is scientifically designed, and can be freely adjusted as you like. Its excellent rigidity has improved the flexibility of the inspection instrument. In this regard, it is especially suitable for grinding and processing the parts.

Main Parameters of Precision Inspection Bench Center

1) Radial rotation precision: 0,001mm

2) Depth of parallelism between the side rail and the tip-tip connection line: 0.005mm (I type)

3) Maximum Diameter of the Tested Part: 250mm

4) Maximum Length of the Tested Part: 500mm, 800mm.

Related Names

Precision Gage | Machine Parts Measurement Device | Detection Instrument

Links:https://www.globefindpro.com/products/39401.html

-

Gantry Drilling-Milling Machine

Gantry Drilling-Milling Machine

-

Granite Square Block

Granite Square Block

-

Magnetic V-block

Magnetic V-block

-

CNC Machine Shock Mount

CNC Machine Shock Mount

-

Anti-vibration Mount (Yellow)

Anti-vibration Mount (Yellow)

-

Floor Type Face Milling Machine

Floor Type Face Milling Machine

-

Single-arm Milling Machine

Single-arm Milling Machine

-

Show Case of Our Products

Show Case of Our Products

-

Gear Bench Center

Gear Bench Center

-

Adjustable Shock Mount

Adjustable Shock Mount

-

Granite Square Ruler

Granite Square Ruler

-

Multifunction Face Milling Machine

Multifunction Face Milling Machine