Syrup Cooking Equipment

Syrup Cooking Equipment

QH600/1200 Weighting and Batching Sugar Dissolving System

The QH600/1200 automatic weighing and batching sugar dissolving system is a fully automatic PLC programming control system. It can automatically mix and pre-cook sugars. The produced syrup can be transported to one or more production lines for use. Necessary for continuous production, this system is suitable for the automatic production of candies and beverages.

Sugar, glucose, and other excipients are weighed and automatically fuse and dissolve. Liquid excipients are accurately weighed and pumped into the mixing tank under the control of PLC system. The recipe can be prepared in advance in the PLC. All raw materials are fully mixed and the melted syrup is pumped into the temporary storage tank for use by other equipment.

Model | QH600 | QH1200 |

Production Capacity | 500kg | 1000kg |

Total Power | 8kw | 12kw |

Steam Pressure and Consumption | 0.3-0.6MPa, 100kg/h | 0.3-0.6MPa, 180kg/h |

Compressed Air Pressure and Consumption | 0.4-0.6MPa, 0.5L/H | 0.4-0.6MPa, 0.7L/H |

Overall Dimensions | 2500×1300×3500mm | 3000×1500×3500mm |

Weight | 1600kg | 2000kg |

QH200/300 Sugar Dissolving Pot

Volume | 300L |

Working Pressure | 0.15MPa |

Operating Temperature | 120℃ |

Gear Pump

Diameter of the Inlet and Outlet | 1'' |

Flow | 3.3m3/h |

Discharge Pressure | 0.32Mpa |

Motor | 1.1kw |

QH200/300 Sugar Storage Tank

Power | 0.75kw |

Diameter of the Storage Tank | Φ700mm |

Overall Dimensions | Φ800mm ×1700mm |

QH300 Dedicated Cooker for Toffees

This machine is specially designed for the production of candies with scorch aroma, such as toffee, caramel, etc. The steam jacket heating and internal scraping stirring effectively prevent the massecuite coking during cooking.

Production Capacity | 300kg/h |

Power of the Complete Machine | 5.5kw |

Weight of the Complete Machine | 1500kg |

Syrup Weight of Single Pot | 160kg |

Cooking Time | 35min |

Steam | 300kg/h, 0.7Mpa |

Overall Dimensions | 1800×1450×2350mm |

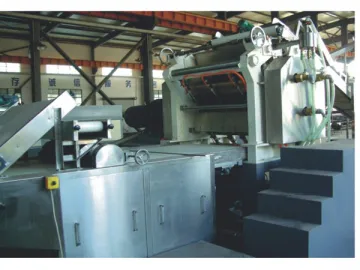

QH400 Vacuum Continuous Cooking Machine

The syrup goes from the dissolving pot through the dosing pump to the heating tube, where the syrup is heated and concentrated by the steam. Then it goes into the intermediate storage pot. Finally it goes into the vacuum pot through the dump valve. Under the action of the vacuum, the syrup changes into the finished products. This machine has many advantages, such as reasonable structure, easy operation, stable performance, convenient maintenance, long lifespan, etc.

Production Capacity | 350-400kg/h |

Heating Area | 2.45m2 |

Steam | 0.5-0.7Mpa, about 100kg /h |

Temperature of the Syrup When Entering the Cooking Machine | 110-115℃ |

Matched Power | Dosing Pump 0.75kw, Vacuum Pump 5.5kw |

Temperature of the Discharged Product | 135-145℃ |

Overall Dimensions | 1900×1700×2300mm |

Weight of the Complete Machine | 800kg |

Ultra-thin Film Vacuum Continuous Syrup Cooking Machine

This cooking machine adopts the ultra-thin vacuum instantaneous concentrator which can also be used as a preheater. The concentrator has internal and external heating chambers. Flowing in the gap between the internal and external heating chambers, the concentrated material is heated on both sides.

Water inside the sugar is heated, vaporized, superheated in the concentrator to form steam bubbles covered by massecuite film, which are called sugar bubble base. The steam bubble will fracture after the sugar bubble base enters the vacuum evaporation chamber. Water vapor is vacuumed out and the water inside the massecuite film will be further evaporated. After water balance, the sugar film falls and accumulates, which is the finished massecuite. According to quality requirements of various massecuites, first or secondary concentration can be adopted.

Production Capacity | 300kg /h |

Compressed Air | >0.3Mpa, 500L /H |

Steam | 0.4-0.6MPa, 600-800kg/h |

Vacuum | >0.2MPa, 5t/h, <30 ℃ |

Power | 28kw |

Overall Dimensions | 3200×1500×4200mm |

Weight | 4000kg |

Material | 304 Stainless Steel |

QH300/450/600 Vacuum Continuous Film Syrup Cooking Machine

This cooking machine is composed of syrup dosing pump, preheater, vacuum thin film evaporator, water ring vacuum pump, discharge pump, temperature and pressure measuring instruments, electrical control box, and other components. All these parts are set up on the same rack and are connected by various pipes and valves. With high production capacity and easy operation, this machine can produce sugar with high quality and a high degree of transparency.

Production Capacity | 300/450/600kg/h |

Steam Consumption | 150/200/250kg/h |

Steam Pressure | 0.5-0.8MPa |

Total Power | 13.2/16.7/22kw |

Overall Dimensions | 2400×2000×2400mm |

Weight of the Complete Machine | 1200/1300/1400kg |

QH300 Continuous Syrup Cooking and Inflatable Blender for Milk Candies

The imported advanced QH300 continuous syrup cooking and inflatable blender adopts the heating, concentrating, stirring and inflating of traditional inflatable candies for the highly inflatable candy production line. This machine is suitable to produce toffee, nougat, milk sugar, chews candy, etc.

Production Capacity | 300kg/h |

Main Motor Power | 11kw |

Vacuum Pump Power | <4kw |

Steam | <200kg/h, 0.7MPa |

Cooking Weight of Single Pot | 1500kg |

Compressed Air | <0.25m3, 0.6MPa |

Vacuum | -0.04MPa |

Inflation Pressure | 0.3MPa |

Overall Dimensions | 2500×1500×3800mm |

Links:https://www.globefindpro.com/products/39579.html

-

Die Formed Candy Production Line

Die Formed Candy Production Line

-

Cake Production Line

Cake Production Line

-

Deposited Lollipop Production Line

Deposited Lollipop Production Line

-

Compound Potato Chips Production Line

Compound Potato Chips Production Line

-

Simple Automatic Adhesive Tape Cutter

Simple Automatic Adhesive Tape Cutter

-

Roll to Roll Continuous Free Label Die Cutter (With Gold Foil)

Roll to Roll Continuous Free Label Die Cutter (With Gold Foil)

-

Jelly Candy Production Line

Jelly Candy Production Line

-

Central Filled Soft Candy/Toffee Production Line

Central Filled Soft Candy/Toffee Production Line

-

Fully Automatic Wafer Production Line

Fully Automatic Wafer Production Line

-

French Bread /Bun Production Line

French Bread /Bun Production Line

-

Layer Cake & Swiss Roll Production Line

Layer Cake & Swiss Roll Production Line

-

Chocolate Coating Machine/Enrober

Chocolate Coating Machine/Enrober