Die Formed Candy Production Line

Die Formed Candy Production Line

QH350 Die Formed Hard Candy Production Line

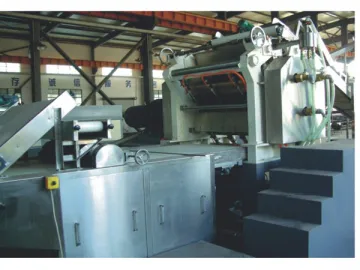

The QH350 die formed hard candy production line adopts the vacuum continuous cooking of sugar, ensuring the quality of the massecuite. Filling, pulling and forming are synchronously controlled and the independent forming way yields better filling effect. Cooling of the candies is ensured by the conveying cooling system. Candies with different shapes can be made by the adoption of different moulds. Spherical lollipops can also be produced by using an automatic stick inserting system.

Devices for the Production of Hard Candy

Sugar Dissolving Pot → Sugar Storage Tank →Vacuum Continuous Cooking Machine → Cooling Bench → Batch Roller → Strip Pulling Machine → Forming Machine → Freezer

Specifications

Name | Overall Dimensions(mm) | Power(kw) | Weight(kg) | Production Capacity |

Batch Roller | 2100×600×1150 | 4.75 | 450 | 3-4t/8h |

Strip Pulling Machine | 1400×800×1300 | 3.3 | 430 | |

350 Hard Candy Forming Machine | 1250×700×1350 | 2.2 | 700 | |

Cooling Screen | 2600×500×700 | 1.5 | 120 |

Figures of the products produced by this equipment are as follows.

QH60 Die Formed Lollipop Production Line

The QH60 die formed lollipop production line is specially used for the production of spherical lollipops. It has a high output and the produced lollipop has beautiful appearance. The whole line is composed of batch roller, strip pulling machine, forming machine and cooling screen.

Devices for the Production of Lollipop

Sugar Dissolving Pot → Sugar Storage Tank→ Vacuum Continuous Cooking Machine → Cooling Bench → Batch Roller → Machine for the Evenly Drawing of Sugar Strips → Spherical Lollipop Forming Machine → Freezer

Specifications

Name | Overall Dimensions | Power | Weight | Production Capacity |

Batch Roller | 2100×600×1150 | 4.75 | 450 | 2.4-4 t/8h |

Pulling Machine | 1400×800×1300 | 3.3 | 430 | |

60 Die Formed Lollipop Forming Machine (with an automatic stick inserting system) | 1500×1000×1200 | 2.2 | 1100 | |

Slope Conveyor | 3300×400×600 | 0.55 | 50 | |

Multi-layer Cooling Vibrating Screen | 2600×1300×2200 | 2 | 400 |

Note: The cooling tunnel of the multi-layer vibrational structure is specially designed for the die formed lollipops. It can maintain the shape and surface smoothness of the lollipop.

Products made by this equipment are shown below.

Links:https://www.globefindpro.com/products/39580.html

-

Cake Production Line

Cake Production Line

-

Deposited Lollipop Production Line

Deposited Lollipop Production Line

-

Compound Potato Chips Production Line

Compound Potato Chips Production Line

-

Simple Automatic Adhesive Tape Cutter

Simple Automatic Adhesive Tape Cutter

-

Roll to Roll Continuous Free Label Die Cutter (With Gold Foil)

Roll to Roll Continuous Free Label Die Cutter (With Gold Foil)

-

Hot Melt Adhesive Lamination Machine

Hot Melt Adhesive Lamination Machine

-

Syrup Cooking Equipment

Syrup Cooking Equipment

-

Jelly Candy Production Line

Jelly Candy Production Line

-

Central Filled Soft Candy/Toffee Production Line

Central Filled Soft Candy/Toffee Production Line

-

Fully Automatic Wafer Production Line

Fully Automatic Wafer Production Line

-

French Bread /Bun Production Line

French Bread /Bun Production Line

-

Layer Cake & Swiss Roll Production Line

Layer Cake & Swiss Roll Production Line