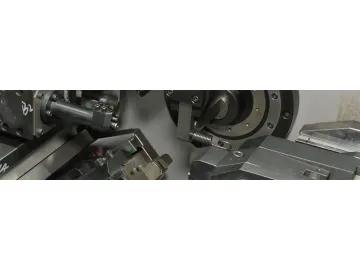

5-Axis CNC Spring Forming Machine

5-Axis CNC spring forming machine comes with 5 axes, including cam, feed, quill, wire rotation and spinner shaft (optional).

This spring former is able to handle wires in a diameter of 1.2-4.0 mm and 0.3-2.5mm, with a maximum feeding speed of 120m/min. It is usually used to produce compression spring, tension spring, torsion spring, scroll spring, tower spring, special-shaped spring, as well as line forming and bending forming products, and other complex products.

Scan QR to Read

Links:https://www.globefindpro.com/products/4012.html

Links:https://www.globefindpro.com/products/4012.html

Recommended Products

-

Electric Scooter, KKA-SCOOTER X1

Electric Scooter, KKA-SCOOTER X1

-

Rugby Turf

Rugby Turf

-

CRBH Series Crossed Roller Bearing

CRBH Series Crossed Roller Bearing

-

DTH Hammer

DTH Hammer

-

Spring Machines

Spring Machines

-

8-Axis High Speed Spring Coiler

8-Axis High Speed Spring Coiler

-

4 Side Seal Packaging Machine, PPD-APGP50 Vaseline Gauze Pad Packaging

4 Side Seal Packaging Machine, PPD-APGP50 Vaseline Gauze Pad Packaging

-

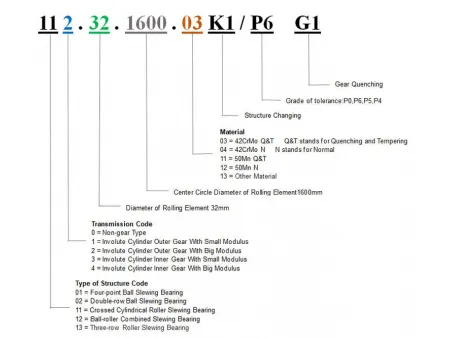

Slewing Rings/ Slewing Bearings

Slewing Rings/ Slewing Bearings

-

Automatic Wire Feeding Machine

Automatic Wire Feeding Machine

-

Sauce Pouch Packaging Machine

Sauce Pouch Packaging Machine

-

5-Axis High Speed CNC Spring Coiler

5-Axis High Speed CNC Spring Coiler

-

Pet Turf

Pet Turf

Hot Products