Metal Chip Briquetting Press (with Double Discharge Chute)

Advantages:

1. Much lower noise

2. Small area occupation

3. Free installation

4. Much lower consumption

5. High output

6. Fast speed

7. Industrial chiller to guarantee longer working time (continuously working more than 16 hours per day, even 24 hours per day)

8. High production capacity: 1.5-2.0Tons per hour

Application:

This series has two models available. They are YS15-30-100 with 250Tons capacity and YS15-67-323 with 360Tons capacity. The most available materials of the machines to be briquetted are the aluminum or aluminum alloy scrap, aluminum or aluminum alloy dust, short or long aluminum or aluminum alloy shavings.

The production capacity of the metal processing machine is 1500kgs to 2000kgs per hour, shift capacity is up to 16000kgs (16Tons).

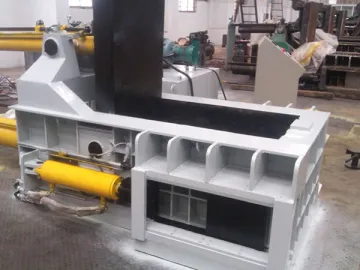

The Y83-22-80 series metal chip briquetting press with double discharge chute is designed to press scrap metal into high density briquettes for high capacity operations.

The density of these scrap briquettes can reach 2.3T/m3 and can be put into a recycling or smelting furnace directly. These hydraulic presses were specifically designed with a horizontal structure for double mold discharging and a screw feeder system to greatly improve efficiency.

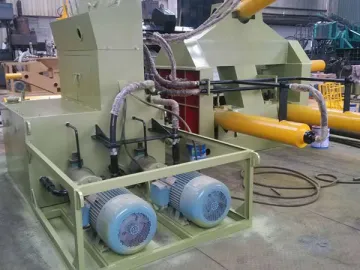

Machine side

The top feed hopper feeds the materials with its spiral structure

Global placement of the equipment including feeding and discharging

Discharge of cylindrical briquettes from the double discharge chute

Discharge of square briquettes from double discharge chute

Briquettes in the trolley

Links:https://www.globefindpro.com/products/40331.html