Two Color PVC Slipper Injection Molding Machine

Rotary air blowing injection molding machine for producing plastic slippers and sandals  The PVC air blowing injection molding machine is used to produce one-color and two-color PVC slippers and sandals; The PCL control system is flexible to perform multiple tasks and operations; The operation system is designed to be easy to learn and convenient to operate; The slipper making machine features large injection volume and strong clamping force; The feeding nozzle switch saves working time and increases output; The dual-ratio hydraulic control valve enables adjustment of feeding speed and injection volume; The machine is used to produce V-shape shoes in one color and two colors. Products are made based on specific needs. Technical Specifications

The PVC air blowing injection molding machine is used to produce one-color and two-color PVC slippers and sandals; The PCL control system is flexible to perform multiple tasks and operations; The operation system is designed to be easy to learn and convenient to operate; The slipper making machine features large injection volume and strong clamping force; The feeding nozzle switch saves working time and increases output; The dual-ratio hydraulic control valve enables adjustment of feeding speed and injection volume; The machine is used to produce V-shape shoes in one color and two colors. Products are made based on specific needs. Technical Specifications

Raw material: PVC

Applications:

One-color/two-color slippers and sandals

| Item | Unit | Specifications | |

| Model | 720D | 724D | |

| Raw material | PVC | PVC | |

| Max. number of stations | 20 | 24 | |

| Clamping force | T | 80 | 80 |

| Mold height | mm | 50-300 | 50-300 |

| Screw diameter | mm | Ø70,Ø60 | Ø70,Ø60 |

| Screw rotational speed | RPM | 0-150 | 0-150 |

| Max. injection volume | cm³/cc | 770,565 | 770,565 |

| Rated injection pressure | kg/cm² | 0-120 | 0-120 |

| Motor power | kW | 18.5,15 | 18.5,15 |

| Power of heating | kW | 13,11 | 13,11 |

| Temperature setting | stage | 4 | 4 |

| Max. mold size | mm | 400*220*300 | 400*220*300 |

| Machine dimensions | mm | 8200*7550*2650 | 8300*7650*2650 |

| Gross weight | kg | 14000 | 14500 |

Scan QR to Read

Links:https://www.globefindpro.com/products/404.html

Links:https://www.globefindpro.com/products/404.html

Recommended Products

-

Shaped Pouch

Shaped Pouch

-

Multi-Color EVA Compression Molding Machine with Vacuum Hood

Multi-Color EVA Compression Molding Machine with Vacuum Hood

-

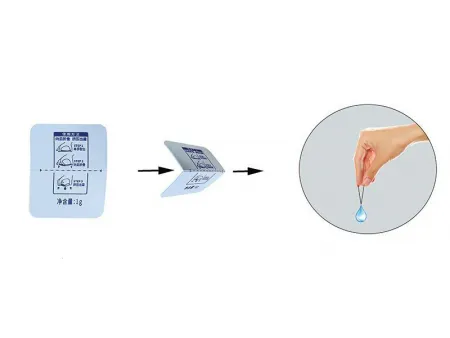

Skincare Products

Skincare Products

-

One-Hand Opening Sachet

One-Hand Opening Sachet

-

Three Color PVC Slipper Upper Injection Molding Machine

Three Color PVC Slipper Upper Injection Molding Machine

-

Rotary Drill Bits

Rotary Drill Bits

-

Light Curing Resin 3D Printer

Light Curing Resin 3D Printer

-

Plastic / Laminated Tube

Plastic / Laminated Tube

-

Pills

Pills

-

One Color EVA Injection Molding Machine

One Color EVA Injection Molding Machine

-

Three Color PVC Rain Boot Injection Molding Machine

Three Color PVC Rain Boot Injection Molding Machine

-

Stand Up Pouch

Stand Up Pouch

Hot Products