QG-PCB30 Precision Cutter, Automatic & Manual

Metallographic Precision Cutting Machine Cut-off wheel:Φ180×1×Φ22mm Max. cutting capacity:Φ 30mm Motor: DC brushless, 1.2 kW Cutting method: Automatic/Manual, Spindle feeding or table feeding Request a quote Features QG-PCB30 precision cutter adopts a speed adjustable motor to drive the cut-off wheel for cutting and it allows for manual and automatic operation. Based on the sample material and personal habits, the cutting can be controlled by hand-operated wheel or by cutting table propulsion. Automatic cutting mode is also available based on set parameters. Exquisite overall design: built-in stainless stell circulating filter cooling water tank adopts 80% water and 20% cutting fluid for lubricating the cutting blade and sample. This effectively prevents the sample surface from heat burn, and protects the rail and ball screw form rusting. The machine automatically stops when opening the cover. This safty protection enables the working area being enclosed. The transparent cover is for observation. The cutting table is available for different clamp tools and the clamp device can be disassembled for cleaning, improving the machine practicality. Cutting samples Automotive air filting aluminum alloy parts Petrographic sample Cutting thick samples of curved silicon glass Cutting thick samples of curved silicon glass Technical Data Feeding speed: manual/automatic, 1-36mm/min (adjusted in steps of 0.1mm/min, max. speed is at zero load) Max. travel: spindle travel: 140mm, table travel: 230mm Spindle speed: 500-3000r/min Cutting table: 245×415mm with 8mm T slot Clamping tool: quich clamp with 45mm jaw height; vertical clamp with 27mm opening Display and control: 5.7 inch touch screen Pump flow: 16L/min Dimensions: 620×740×380mm Net weight: 80kg

Scan QR to Read

Links:https://www.globefindpro.com/products/4054.html

Links:https://www.globefindpro.com/products/4054.html

Recommended Products

-

QGZ-65 Metalloraphic Abrasive Cutter, Automatic

QGZ-65 Metalloraphic Abrasive Cutter, Automatic

-

D Series Horizontal Multistage Centrifugal Pump

D Series Horizontal Multistage Centrifugal Pump

-

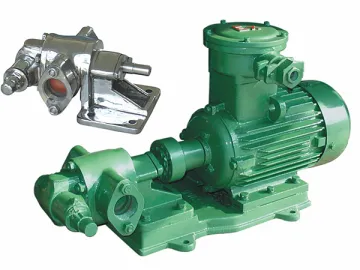

Gear Pump

Gear Pump

-

HBRV-187.5 Universal Hardness Tester

HBRV-187.5 Universal Hardness Tester

-

Double Suction Centrifugal Pump

Double Suction Centrifugal Pump

-

Automatic Straight Tube Tablet Bottling Machine, TF-120

Automatic Straight Tube Tablet Bottling Machine, TF-120

-

Centrifugal Chemical Pump

Centrifugal Chemical Pump

-

YZXQ-3 Hot Mounting Press with Two Cylinders, Hydraulic Type

YZXQ-3 Hot Mounting Press with Two Cylinders, Hydraulic Type

-

AOK Air Operated Diaphragm Pump

AOK Air Operated Diaphragm Pump

-

HD/SB Series Liquid Transfer Drum Pump

HD/SB Series Liquid Transfer Drum Pump

-

XHVT-10Z30Z50Z Vickers Hardness Tester with CCD Camera

XHVT-10Z30Z50Z Vickers Hardness Tester with CCD Camera

-

MHV-1000Z Digital Micro Vickers Hardness Tester, with Touch Screen

MHV-1000Z Digital Micro Vickers Hardness Tester, with Touch Screen