Multi-Color EVA Compression Molding Machine with Vacuum Hood

Footwear machinery for shoe sole making  The EVA compression molding machine can be operated on one side or two sides, which increases productivity; Busch vacuum pumps ensure stable production and high-quality products; Two molds in one station work independently to double the productivity; Self-compensating mold plates contribute to high product quality. Technical Specifications

The EVA compression molding machine can be operated on one side or two sides, which increases productivity; Busch vacuum pumps ensure stable production and high-quality products; Two molds in one station work independently to double the productivity; Self-compensating mold plates contribute to high product quality. Technical Specifications

Features The compression molding machine is mainly used to manufacture multi-color EVA foam products; The vacuum system ensures the molding process is clean and dust-free to produce high-quality products; The quality thermal insulation panels effectively preserve heat without use of water circulation; The compact structure reduces the occupation of floor space; The footwear machine is user-friendly as it is easy and convenient to operate; Servomotors and a PLC greatly improve efficiency and save energy.

Raw material: EVA

Applications

Multi-color EVA foam products

| Item | Unit | Specifications | ||

| Raw material | EVA | EVA | EVA | |

| Number of stations | 6 | 8 | 10 | |

| Clamping force | mm | 180 | 180 | 180 |

| Mold opening stroke | mm | 350 | 350 | 350 |

| Mold size | mm | 600*330*2sets | 600*330*2sets | 600*330*2sets |

| Mold height | mm | 100-220 | 100-220 | 100-220 |

| Power of motor | kW | 16 | 16 | 16 |

| Power of heating | kW | 77 | 102 | 128 |

| Total power | kW | 93 | 118 | 144 |

| Oil consumption | kg | 600 | 600 | 600 |

| Machine dimensions | mm | 9560*1450*2950 | 11830*1450*2950 | 13850*1450*2950 |

| Gross weight | kg | 30000 | 39000 | 49000 |

Scan QR to Read

Links:https://www.globefindpro.com/products/406.html

Links:https://www.globefindpro.com/products/406.html

Recommended Products

-

Skincare Products

Skincare Products

-

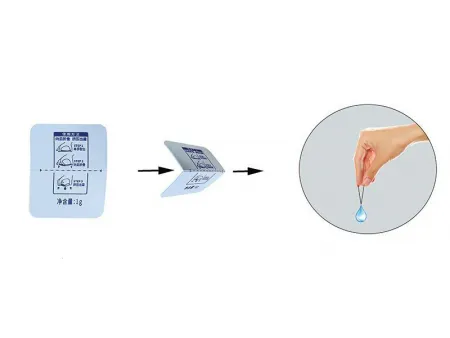

One-Hand Opening Sachet

One-Hand Opening Sachet

-

Three Color PVC Slipper Upper Injection Molding Machine

Three Color PVC Slipper Upper Injection Molding Machine

-

Rotary Drill Bits

Rotary Drill Bits

-

Others

Others

-

Powders & Granules

Powders & Granules

-

Shaped Pouch

Shaped Pouch

-

Two Color PVC Slipper Injection Molding Machine

Two Color PVC Slipper Injection Molding Machine

-

Light Curing Resin 3D Printer

Light Curing Resin 3D Printer

-

Plastic / Laminated Tube

Plastic / Laminated Tube

-

Pills

Pills

-

One Color EVA Injection Molding Machine

One Color EVA Injection Molding Machine