Bed Underpad and Puppy Training Pad Production Line

Model No.

PX-CD-220-SF Full-servo Underpad & Pet Training Pad Production Line

PX-CD-200-BSF Semi-servo Underpad & Pet Training Pad Production Line

PX-CD-180-BP Full-automatic Underpad & Pet Training Pad Production Line

Full-Servo Pet Training Pad Production Line

3 Ply Underpad

5 Ply Underpad

Product Name: Full-servo Underpad & Pet Training Pad Production Line

Completed Products: Bed pad/pet training pad

1. PX-CD-220-SF

Design speed: 300m/min

Regular speed: 220m/min

2. PX-CD-200-BSF

Design speed: 260m/min

Regular speed: 180m/min

3. PX-CD-180-BP

Design speed: 220m/min

Regular speed: 140m/min

Main Equipment Parameters

1. Design speed: 300 meters/min

2. Production speed: 220meters/min(width 600mm)

200meters/min(width 800mm)

3. Overall dimensions: 22m(L)×3.5m(W)×2.5m(H)

4. Machine power: approx 300KW (380V, 50Hz)

5. Machine weight: about 70 T

Brief Description

Can produce 3-ply (PE film, fluff pulp, non-woven fabrics) or 5-ply (PE film, bottom-layer tissue, fluff pulp, top-layer tissue, non-woven fabrics) mattress pad & pet training pad, at high speed.

Raw Material Specs

1. Cotton core: 34g/m2 (includes top and bottom-layer tissue, fluff pulp, which can be untreated, semi-treated or treated pulp, as well as recycled pulp)

2. Non woven fabrics: 9g/m2

3. PE/PP: 15g/m2

4. SAP: 8g/m2

Raw Material Unwinding Diameter and Weight:

1. Top and Bottom Layer Tissue Roll Diameter: Φ960mm Weight: 125kg

2. Non woven fabrics Roll Diameter: Φ960mm Weight: 125kg

3. PE/PP Roll Diameter: Φ600mm Weight: 60kg

4. Wood pulp Roll Diameter: Φ1500mm Weight: 500kg

Finished Product Folding Method

1. C-fold, requiring two or three folds

2. Z-fold, requiring two or three folds

3. W-fold, requiring two or three folds

Bed Pad

Links:https://www.globefindpro.com/products/40867.html

-

Wet Wipes Folding Machine, 80 Pieces

Wet Wipes Folding Machine, 80 Pieces

-

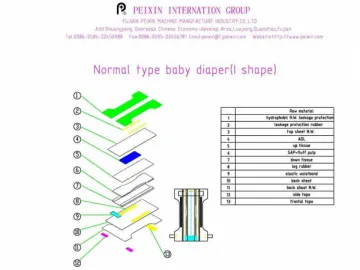

Baby Diaper Production Line (I-Shape)

Baby Diaper Production Line (I-Shape)

-

Stacking Machine

Stacking Machine

-

Toilet Paper Rewinding and Perforating Machine (1575A)

Toilet Paper Rewinding and Perforating Machine (1575A)

-

Baby Diaper Production Line (T-Shape)

Baby Diaper Production Line (T-Shape)

-

Adult Diaper Production Line

Adult Diaper Production Line

-

Wet Wipes Folding and Packing Machine, 5-30 Pieces

Wet Wipes Folding and Packing Machine, 5-30 Pieces

-

Sanitary Napkin Production Line

Sanitary Napkin Production Line

-

Oil Bleeding Solid Silicone Rubber for Automobile Coil Linkspan

Oil Bleeding Solid Silicone Rubber for Automobile Coil Linkspan

-

Peroxide Curing Solid Silicone Rubber (HCR/HTV)

Peroxide Curing Solid Silicone Rubber (HCR/HTV)

-

Hydroxyl Terminated Vinyl Silicone Oil

Hydroxyl Terminated Vinyl Silicone Oil

-

Toilet Paper and Kitchen Towel Packing Line

Toilet Paper and Kitchen Towel Packing Line