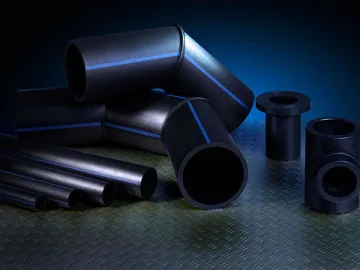

PVC-U Drainage Pipes and Fittings

Kingbull's PVC-U drainage pipes and fittings are all manufactured from high quality PVC with additives to the standards of GB/T5836.1-2006, GB/T5836.2-2006 and JG 3050-1998. We pride ourselves on getting hold of professional expertise and know-how in production of the PVC-U pipes and fittings which will provide excellent quality and higher safety and reliability.

Features of the PVC-U Drainage Pipes and Fittings

1. New generation PVC-U technology and exclusive additive formula enable us to produce the drain pipes and fittings with remarkably improved toughness and impact strength while maintaining high rigidity.

2. The raw materials and additives are rigorously selected. For example, we purchase top quality PVC resin in domestic market and introduce additives such as heat stabilizers, lubricating agents, etc. from first class enterprises in China or foreign countries.

3. We use automatic dosing system under complete computer control. It will ensure stable material dosing and consistent product quality. In addition, we use lean manufacturing equipment to make materials fully plasticized, ensuring further improved density and impact strength.

4. Our PVC-U fittings feature professional structure design which eliminates stress structure defect, elegant appearance with less prone to damage and superior performance.

5. At Kingbull, we have an industry leading national level laboratory. We can conduct the strictest quality control to the production from raw materials and additives selection, production and final products.

PVC-U Drainage Pipes Categories

According to shapes, they are divided into solid wall plastic pipes and non-solid wall plastic pipes. Among them, the non-solid wall products include corrugated pipe, pipe with a sandwich, pipe with a foam core, and rifled pipe.

According to working pressures, they are divided into pressure pipes and non-pressure pipes. The former includes PVC, PVC-M, PVC-O and other water supply pipes and the latter includes underground drainage pipes (Double-wall corrugated pipe), underground cable protective pipes (solid wall, corrugated) and building drainage pipes (indoor and outdoor rain pipe).

Specifications

| Name | Specification (mm) | Packing size(m/ pcs) |

| PVC-U drainage pipe | 50 × 2.0 | 4 |

| 75 × 2.3 | 4 | |

| 110 × 3.2 | 4 | |

| 160 × 4.0 | 4 | |

| 200 × 4.9 | 4 | |

| 250 × 6.2 | 4 | |

| standard: GB/T 5836-2006 | ||

| Name | Specification (mm) | Packing size(m/ pcs) |

| PVC-U solid wall spiral pipe, with silencing function | 75 × 2.3 | 4 |

| 110 × 3.2 | 4 | |

| 160 × 4.0 | 4 | |

| PVC-U hollow spiral pipe, with silencing function | 75 | 4 |

| 110 | 4 | |

| 160 | 4 | |

| Name | Specification (mm) | Packing size(m/ pcs) |

| PVC-U rain pipe | 110 | 4 |

| Name | Specification (mm) | Packing size(m/ pcs) |

| PVC-U double wall corrugated pipe | 110 | 6 |

| 160 | 6 | |

| 200 | 6 | |

| 250 | 6 | |

| 315 | 6 |

PVC-U Drainage Pipe Fittings Categories

Coupling

45° Elbow

45° Equal Cross

45° Reducing Cross

90° Elbow

90° Elbow with a Check Hole

Coupling with a Check Hole

Trap

Trap with a Check Hole

Square Roof Drain

Reducing Tee

Equal Tee

Cleanout (end cap)

Bottle Shape Tee

P-Trap

P-Trap with Cleanout

Eccentric Reducer

S-Trap

S-Trap with Cleanout

45° Equal Tee

45° Reducing Tee

Reducing Cross

Four-Way Tee

Equal Cross

Trap with Cleanout

Floor Drain

Simple Floor Drain

Round Water Seal Floor Drain (Deepened

Floor Drain for Washing Machine

Roof Drain

Multi-purpose Floor Drain

Ventilation Cap

H-Shaped Pipe

Seal Ring

Reducer for Toilet Pan

Threaded Expansion Coupling

Stack Pipe Fitting

Simple Expansion Coupling

Expansion Coupling

Equal Cross with Silencing Function

Reducing Tee with Silencing Function

Equal Tee with Silencing Function

Coupling with Cleanout

Conduit Box, 4 Way Side Entry

PVC Tee

Conduit Box, 2 Way Through

Conduit Box, 2 Way Angle

Conduit Box, 3 Way Side Entry

Conduit Box, 1 Way Side Entry

Conduit Box, 1 Way Side Entry

Deep-Type Conduit Box, 2 Way Through

Deep-Type Conduit Box, 2 Way Angle

Deep-Type Conduit Box, 3 Way Side Entry

Deep-Type Conduit Box, 4 Way Side Entry

Why Kingbull PVC-U Drainage Pipes and Fittings?

1. Modern and Scientific Production Management Mode

Kingbull applies automatic dosing system remotely controlled by computer. It handles the problems that manual dosing often results in high labor cost, material loss and chemical damage to operators. Meanwhile, it improves dosing accuracy and ensuring consistency of product quality.

We use efficient pneumatic conveying system that replaces the onerous manual works, improving production efficiency. The whole material handling process is completed in closed pipes, thus avoiding dust flying in the workshops and protecting the operators. Material preparation and processing is more centralized and efficient, ensuring higher output.

2. Specialized PVC-U Pipes Extrusion Equipment and Injection Molds

Our PVC-U pipe extruder employs self-designed conical twin screw which available in various diameters and lengths. The screws with proper diameters and length-diameter ratios will be used for extruding pipes in different specifications, so as to improve production output and ensure plasticizing quality as well.

The runner of die head features streamline design without dead angle, and the surface has been electroplated and polished. This avoids material stacking and thereby prevents other problems because of that. Additionally, the die heads used come with the most appropriate compression ratio. It is known that too small compression ratio of die head leads to less density of extruded products and insufficient adhesion of joint line, and over large compression ratio speeds down extrusion and thereby improves cost.

Pipe fitting molds also come with scientific streamline design which reduces stress concentration and ensures higher impact strength of fittings.

With advanced subsurface design, the sprue is solid, flat and eye-pleasing, with fully relief of stress and high strength. Reasonable cooling system design assures the dimensional stability of products.

Mold core is made of stainless steel imported from Germany. It ensures the degree of finish and dimensional accuracy of pipe fittings.

3. Elaborately Selected Materials and Traceable Management System

R&D engineers in Kingbull select the raw materials for our PVC drainage pipes and fittings meticulously, so as to ensure the best performance. PVC pipes are mainly composed of PVC resins and stabilizing agent, lubricating agent, modifying agent, filling agent, coloring agent, etc. according to a certain proportion. The selection of each material is conducted regarding the applications and properties of PVC pipes.

(1) PVC Resins

We only use the PVC resins from renowned large sized petrochemical corporations. They are sure to offer stable and reliable quality.

Macro Particles

Section of a Particle

Primary Particle Aggregate and Integument

Primary Particles

(2) Stabilizing, Lubricating and Modifying Agents

The stabilizing agents are from domestic famous enterprise and the lubricating and modifying agents are imported. We carry out dynamic rheological test using torque rheometer to differentiate superior and inferior agents.

(3)Filling Agent

The biggest filling agent that use in our PVC-U pipes is calcium carbonate which is mainly used to improve pipe's rigidity and hardness and slightly increase heat deflection temperature, thus reducing thermal expansion coefficient, lowering molding shrinkage and enhancing dimensional accuracy.

Selected calcium carbonate comes with high whiteness and fine and evenly distributed particles. State of the art laser particle sizing instrument and whiteness measuring device are used to ensure the material's stability.

(4) Impact Modifier

We use famous brand Chlorinated Polyethylene (CPE) as the PVC impact modifier. And we use muffle furnace and drying oven to strictly control the ash content and volatile matter in the CPE, ensuring the final PVC pipes come with high impact strength.

(5) Coloring Agent

According to different purposes, PVC-U pipes and fittings are available in white, gray and many other colors. So coloring agent is indispensably used in the production of this plastic pipes. The most commonly used coloring agents include titanium dioxide and carbon black.

Kingbull introduces rutile titanium dioxides from large and well-known suppliers. They feature high whiteness, fine grain size, good cladding and superior aging resistance. When added to the PVC pipes, they allow the pipes to resist long time exposure to sun without color changing.

4. Cutting-Edge Technology and Rigorous Quality Management

Specific techniques can maximize the performance of PVC products. Technological parameters are closely related to production formula and equipment. A great process condition is corresponding to specific formula and equipment.

Screw barrel temperature, screw speed, die head pressure and pulling speed are important technological parameters in pipe extrusion; cylinder temperature, nozzle temperature and mold temperature of injection molding machine, plasticizing pressure and injection pressure are important parameters in injection molding of pipe fittings. Relevant technological parameters are made for specific formula and equipment.

Kingbull's PVC-U drainage pipes have passed the international immersion test in 4L methylene dichloride. This certifies that the pipes come with higher impact strength and better weather resistance.

Links:https://www.globefindpro.com/products/41077.html

-

PPR Stabi Composite Pipes and Fittings

PPR Stabi Composite Pipes and Fittings

-

PE Pipes and Fittings (Outdoor Use)

PE Pipes and Fittings (Outdoor Use)

-

Double Wall Corrugated Pipes

Double Wall Corrugated Pipes

-

Three-Phase Induction Motor, YE2 Series

Three-Phase Induction Motor, YE2 Series

-

Municipal Drain Pipe System

Municipal Drain Pipe System

-

PEX Pipes and Fittings

PEX Pipes and Fittings

-

PE-AL-PE Multilayer Pipes and Fittings (Indoor Use)

PE-AL-PE Multilayer Pipes and Fittings (Indoor Use)

-

PE Pipes and Fittings (for Water Supply)

PE Pipes and Fittings (for Water Supply)

-

PE-AL-PE Multilayer Pipes and Fittings (Indoor Use)

PE-AL-PE Multilayer Pipes and Fittings (Indoor Use)

-

PPR-Steel-PPR Composite Pipes and Fittings

PPR-Steel-PPR Composite Pipes and Fittings

-

PE Pipes and Fittings (for Water Supply)

PE Pipes and Fittings (for Water Supply)

-

PPR Stabi Composite Pipes and Fittings

PPR Stabi Composite Pipes and Fittings