I-Shaped Straw Wrapping Machine, JH04-I

Our JH04-1 drinking straw wrapping machine is used to wrap the straight straws made by our JH01 series extrusion equipment or the flexible straws by JH02 series post extrusion equipment into a BOPP film pack with four sides sealed. The straws are mainly used for sucking beverage. Each straw is individually wrapped and connected one by one in parallel type. The shrink wrap machine delivers counting and slitting functions.

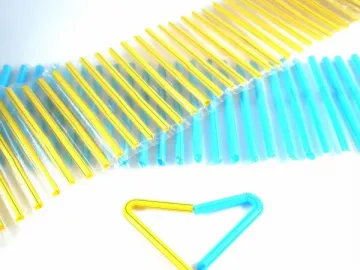

Wrapped Straws

Equipment Show

Advantages of the Straw Wrapping Machine

1. Compact structure, ease of operation, high automation and high efficiency;

2. Slitting function for cutting connected packs into individual ones: Available in discontinuous hot cutting and continuous cold cutting;

3. High packing size stability and consistency;

4. Due to variable frequency control, the flexible straw packing machine is power saving and runs stably;

5. Auto-stop function for handling overload problem;

6. Automatic counting function and warning as pre-set wrapping quantity is reached

| Model | JH04-I |

| Straw size | Diameter: 2.5-7.0mm Length: 100-230mm |

| Wrapping size | Gap between straws: 16mm (Or according to customers) |

| Speed | >400pcs/ min |

| Packing Material | BOPP hot sealing film |

| Motor Power | 0.75Kv 0.4Kv |

| Total power | 3Kw(220V) |

| Dimension (L ×W ×H) | Heat sealing machine : 1500 ×800 ×1600mm Cutter: 1000 ×800 ×1200mm |

| Weight | 800Kg |

Links:https://www.globefindpro.com/products/41361.html

-

5-30L Chemical Packaging Machine

5-30L Chemical Packaging Machine

-

Drinking Straw Collecting Device

Drinking Straw Collecting Device

-

Optional Auxiliary Machine (for Drinking Straw Making)

Optional Auxiliary Machine (for Drinking Straw Making)

-

Individual Straw Wrapping Machine

Individual Straw Wrapping Machine

-

Corrosive Liquid Packaging Line

Corrosive Liquid Packaging Line

-

Drinking Straw Forming Machine

Drinking Straw Forming Machine

-

Individual Straw Wrapping Machine, JH03-G

Individual Straw Wrapping Machine, JH03-G

-

Spare Parts

Spare Parts

-

Two-Color Drinking Straw Extrusion Line

Two-Color Drinking Straw Extrusion Line

-

50-1000ml Chemical Packaging Machine(for Low-Viscous Liquid)

50-1000ml Chemical Packaging Machine(for Low-Viscous Liquid)

-

Creative Straw Forming Machine

Creative Straw Forming Machine

-

Multi-Color Drinking Straw Co-extrusion Line

Multi-Color Drinking Straw Co-extrusion Line