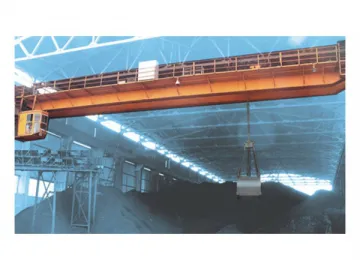

Insulated Overhead Crane

Insulated overhead crane is widely used in metallurgical plants to handle the electrolysis equipment for aluminum, magnesium and other nonferrous metals. The overhead lifting equipment is mainly made up from four parts including box shape girder, end trucks, trolley and electrical equipment. To protect the driver from electric shock in material handling, the bridge crane for steel industry is equipped with insulation devices at some electriferous parts. In addition, it adopts double brake to ensure totally safe lifting.

Specifications of Insulated Overhead Crane

Other Images

Specifications of Insulated Overhead Crane

| Lifting Weight | T | 5-100 |

| Span | m | 10.5~31.5 (Extendable) |

| Lifting height | m | 6-16 ( Extendable) |

| Operating methods | Cabin | Driver cabin with broad vision, toughened glass, ergonomic seat |

| Power supply | AC | 3-Phase A.C. 50HZ 380V |

| Classification | A6 | |

| Hoisting mechanism | Integral design of motor, reducer, coupling and wire rope reel make the hoisting mechanism compact and safet | |

| Main electric parts | Schneider or Siemens (Optional) | |

| Overload protection device | Rotary cam, 4-step adjustable, auto reset, height adjustable, precise phase-sequence control | |

| Crane traveling limit switch | Multiple limit protection devices including PU, IR sensor, etc. | |

| Steel structure parts | Independently designed and manufactured by Zhonggong which boast industry leading technology and manufacturing strength | |

| Motor | State of art brand in domestic market (Optional) | |

| Electrical control system | Variable frequency control, PLC, human-machine interface | |

| Reducer | Top brand in China or overseas brands such as SEW, Flanders, etc. | |

| Wire rope | Wire rope with high strength fiber core or steel core | |

| Brake | Double hoisting brake with brand optional | |

| Hooks | Hardened and tempered steel: 34CrMoV; T-class hook is made of alloy steel 34CrMoV4 | |

| Wire rope reel | Welded reel, rolled from steel plates; light weight, simple structure and high intensity | |

| Wheel and machining parts | Designed and made by Zhonggong independently, bringing you peace in mind | |

Scan QR to Read

Links:https://www.globefindpro.com/products/42266.html

Links:https://www.globefindpro.com/products/42266.html

Recommended Products

-

Bridge Crane (with Grab)

Bridge Crane (with Grab)

-

Electric Hoist, HC Model

Electric Hoist, HC Model

-

Bridge Crane, Double Girder

Bridge Crane, Double Girder

-

Gantry Crane, Double Girder

Gantry Crane, Double Girder

-

Jib Crane

Jib Crane

-

Semi Goliath Crane

Semi Goliath Crane

-

Gantry Crane (Electromagnetic)

Gantry Crane (Electromagnetic)

-

Bridge Crane, Single Girder

Bridge Crane, Single Girder

-

Gantry Crane, Single Girder

Gantry Crane, Single Girder

-

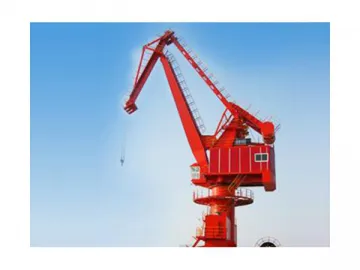

Stationary Slewing Crane

Stationary Slewing Crane

-

Manual Bridge Crane (Single Girder), SLX Model

Manual Bridge Crane (Single Girder), SLX Model

-

Explosion Proof Crane, Single Girder

Explosion Proof Crane, Single Girder