Paper Machine (for Specialty Paper Making)

Applications

The specialty paper production line is widely used for different leather products, including leather bags, belts, clothes, sofas, shoes and more.

Technical Parameters of the Specialty Paper Machine

Product: Regenerated leather

Grammage: 0.6~4g/mm2

Breadth: 1600mm

Working speed: 15~50m/min

Design speed: 80m/min

Rail distance: 2400mm

Driving method: AC Variable frequency speed control, sectional drive

Machine type: Heavy square box, with left and right machine available

Standard: International export standard

Main Structure

1) Headbox

The specialty paper machine comes with an open headbox composed of the taper pipe, stepped diffuser, rectifier roll and box. The top and lower lips of the slice are made of stainless steel, and the top lip can be adjusted both fully and locally.

2) Forming Section

The length of the fourdriner table is 12,500mm. With the exception of the bearing block, which is made of carbon steel, the table frame is welded from structural steel. The forming section of the specialty paper machine primarily consists of the breast roller, forming board, foils, suction boxes, vacuum couch roll, table roll, corrector, wire tightener and edge warping device.

3) Press Section

The press section is comprised of press rolls and dry belts. It uses one vacuum suction pickup roll and three suction rolls. The paper that comes from this section comes with a dryness of 40% or more.

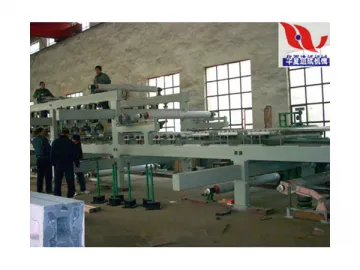

Leather forming

In production

Links:https://www.globefindpro.com/products/42352.html

-

Pulp Moulding Machine, HX6000 Series

Pulp Moulding Machine, HX6000 Series

-

Agitator, LXT Series

Agitator, LXT Series

-

PFC Inductor (with Powder Core)

PFC Inductor (with Powder Core)

-

Low Density Cleaner, KDC Series

Low Density Cleaner, KDC Series

-

Ultra-High Voltage Anode Saturable Reactor, Water-cooled

Ultra-High Voltage Anode Saturable Reactor, Water-cooled

-

Pressure Screen (Inward Flow)

Pressure Screen (Inward Flow)

-

Reject Sorter

Reject Sorter

-

AC Motor (for Range Hood)

AC Motor (for Range Hood)

-

Control Transformer (for Elevator Control)

Control Transformer (for Elevator Control)

-

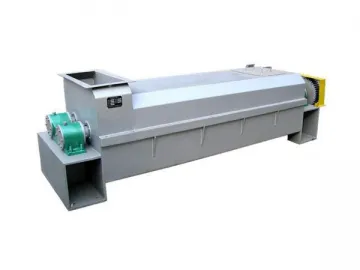

Screw Press (Double Screw), ZSJ Series

Screw Press (Double Screw), ZSJ Series

-

DC Motor (for Vacuum Cleaner)

DC Motor (for Vacuum Cleaner)

-

Disc Thickener

Disc Thickener