High Pressure Grinding Rolls

For over 60 years, CITIC Heavy Industries (CITIC HIC) has been upholding its commitment to technical innovation in the mineral processing industry. Backed by years of experience and in-depth knowledge within the field, CITIC HIC has successfully developed high pressure grinding roll (HPGR) suited to meet global customers' needs of safe, reliable, energy-saving and high-efficiency crushing and grinding operaions.

Key Features Reduced feed particle size: in comparison with conventional crushing and grinding equipment, the high pressure grinding roll can reduce breakage size from 10-20mm down to 3mm or below, thus leading to less energy consumption for grinding process. Lowered Bond work index: through high pressure crushing operation, the Bond work index of most minerals can be significantly lowered, some even have gone down by more than 23%. Strengthened tailings disposal operation prior to downstream grinding: magnetite ore processing technique enables a tailings disposal efficiency of up to more than 30%, helping reduce mill load and energy consumption while lowering the wear rate of mill liners and grinding media. Higher efficiency and improved recovery rate: the minerals crushed by high pressure grinding roll have large quantities of microcracks along the grain boundary, these microcracks enable better adsoption on mineral surface which translates to good permeability in the leaching process of difficult-to-treat ores. Why Choose CITIC HIC's High Pressure Grinding Roll High operating rateCITIC HIC has participated in setting China National Standards of high pressure grinding rolls, promoting the development of large-scale high pressure roller mills towards intelligence in the domestic market. CITIC HIC is always focused on maintaining a leading position within the China's mineral processing market by using international advanced design and manufacturing standards.

Excellent processing performance

Good roller compaction effect, high qaulification rate, providing more than 20% stronger force, more than 15% higher qualification rate and more than 10% less energy consumption than of those of competitors in the domestic market.

Extremely long life cycle

Newly designed bearing structure features a lifespan of over 10 years, which is 3 to 5 times the conventional self-aligning bearing. The rolling friction is more evenly and the service life is longer.

Serving customers worldwide

Our high pressure grinding rolls have been exported to a number of countries such as Australia, Brazil and Russia. The reliable equipment performance and our excellent service are particularly appraised by the world's largest iron ore producer – Brazilian Vale SA, Zijin Mining Group, and other high-end customers. Core Advantage Selection

Our high pressure grinding rolls can be equipped with finish grinding system, cement combined grinding system, semi-finish grinding system, and more processing systems. Our core database and process simulation software can support the selection of machines and systems. Besides, we have technologies for structure improvement of key units and layout optimization of piping system to ensure that the product performance reaches an advanced level at home and abroad.

Roller body is constructed with high performance forged alloy steel by using 18500t hydraulic press and large-scale forging equipment, ensuring high performance and extremely long service life of rollers.

With a split design of roller shaft and shell, operator can only need to change the roller shell (wear parts) and the roller shaft can be long-term use, thus greatly saving the costs of spare parts. Highly wear-resistant roller surface

Roller surface is protected against wear with hard metal studs that enable particle size to be reduced by compressing and grinding, the service life of roller surface is up to 30,000 hours. Lateral wear blocks and lateral walls are used to reduce wear and seal the working gap at roller edges, therefore providing an optimal compression effect.

Efficient stud-lined roller surface repairing technology

Independently developed fast stud changing technology allows to replace broken metal pins (studs) in a timely manner, preventing costly production downtimes caused by large fracture surface of studded roller. Studded lower side plate

Unlike conventional lower side plate that can only last for 5 days, our studded lower side plate features an extended service life of 3 to 6 months. Bearing technology

Bearing load distribution and sealing technology

Bearing loads are distributed more evenly and featured by longer service life, enabling the high pressure grinding roll to be operated more stably and reliably.

The sealing structure combines radial sealing, axial sealing and labyrinth sealing methods to assure a tight seal at all times and efficiently prevent dust penetration.

Bearing diassembly technology

Four-row cylindrical roller bearings can be easily disassembled by simply removing a integrated part of bearing seat and outer ring, eliminating the need for dismantling the inner ring thereby greatly facilitating the maintenance operations while efficiently avoiding the risks of bearing failure.

Bearing cooling technology

The operating temperature of the main bearing can be kept at a appropriate temperature, significantly prolonging the service life of the main bearing.

Quick reducer separation

Rollers can be quickly disassembled from the reducer due to the usage of quick coupling, protecting roller shaft and reducer shaft from being damaged, thus saving the cost of spare parts.

Quick roller changing system

Roller exchange process can be rapidly carried out with quick roller changing unit, which assures safe changing operation while cutting the changing period from original 7 days down to 2 days, as well as greatly saving costs of lifting equipment and civil construction.

Surge bin

We have two types of feed surge bins (fixed and movable) for user to choose from. The movable surge bin is powered by motor to travel along the track for easy maintenance with the help of lifting equipment.

Two-sided electrically adjustable feed unit

This feed unit provides the flexible adjustment during material feeding process.

All parts in contact with materials are made with wear-resistant steel plate, enhancing wear resistance.

Complete protection system

A variety of electronic sensors are used for real-time monitoring of high pressure grinding roll. If any failure occurs, the operator will be immediatelyinformed to solve the issue and ensure the operation at an optimal status.

Metal detection and automatic bypassing system

The design of interlocking control allows metal detector to activate an electric bypass flap gate that diverts the metals to a separate chute, thus preventing the machine damage caused by metals.

| Model | Power | Roll diameter | Roll width | Capacity | Dimensions (L×W×H) |

| kW | mm | mm | t/h | mm | |

| GM120-50 | 2×355 | 1200 | 500 | 180-210 | 6500×4424×2113 |

| GM120-80 | 2×500 | 1200 | 800 | 260-340 | 7627×5710×2340 |

| GM140-60 | 2×500 | 1400 | 600 | 330-380 | 7380×5930×2758 |

| GM140-80 | 2×560 | 1400 | 800 | 390-500 | 7528×5930×2838 |

| GM140-100 | 2×630 | 1400 | 1000 | 440-510 | 8756×5528×2838 |

| GM150-80 | 2×710 | 1500 | 800 | 420-530 | 8800×5810×3590 |

| GM140-110 | 2×800 | 1400 | 1100 | 480-610 | 10467×5140×3120 |

| GM150-110 | 2×800 | 1500 | 1100 | 580-730 | 8400×6110×3590 |

| GM170-110 | 2×1120 | 1700 | 1100 | 830-980 | 10700×6915×3745 |

| GM170-120 | 2×1250 | 1700 | 1200 | 900-1070 | 9950×6915×3983 |

| GM170-140 | 2×1400 | 1700 | 1400 | 1050-1200 | 13415×5725×3330 |

| GM180-160 | 2×1600 | 1800 | 1600 | 1250-1400 | 14035×6680×3586 |

| GM200-150 | 2×1800 | 2000 | 1500 | 1500-1650 | 14800×6870×3920 |

| GM200-180 | 2×2500 | 2000 | 1800 | 1900-2100 | 14900×6960×4120 |

| GM200-200 | 2×2800 | 2000 | 2000 | 2300-2500 | 15093×7045×3859 |

| GM240-180 | 2×3150 | 2400 | 1800 | 2600-2900 | 15800×7135×4300 |

| GM260-180 | 2×3550 | 2600 | 1800 | 3000-3300 | 16500X7650X4420 |

| GM300-200 | 2×5700 | 3000 | 2000 | 5200-5400 | 20500X9950X6100 |

Notes: Detailed values of capacity and infeed material characteristics are associated with processing techniques.

The capacities in the above table are calculated on the basis of medium hardness ores with bulk density of 3.5t/m³.

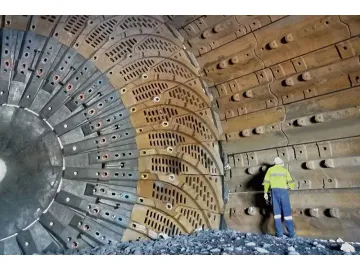

Dimensions are for reference only, and subject to our final drawings. Case Study GM140-60 High Pressure Grinding Roll

The project was being retrofitted in 2010. The type of ore has mineral hardness of f=14-16, silicon content of approximately 48%, and is strongly abrasive. The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvements. The fifth generation roller structure can provide a long service life up to 10,000 hours.

GM160-140 High Pressure Grinding RollIn this project, the mineral hardness is f=10-12 and silicon content is approximately 15%. The equipment was first brought into operation in July 2015, since then the equipment has been running smoothly. The roller surface lifespan can reach 20,000 hours.

GM150-110 High Pressure Grinding RollThis project employs two-part closed-circuit crushing operation and HPGR closed circuit grinding operation incorporating wet screening, the mineral hardness is f=8-12. Since it was first put into operation, the machine running has remained stable.

GM200-180 High Pressure Grinding RollThe project adopts GM200-180 high pressure grinding roll and final grinding process designed by our company, the design output is 500t/h. Currently, the system runs stably and the production capacity ranges between 530t/h and 550t/h, with power consumption of 11-13kWh/t.

GM160-140 High Pressure Grinding RollThis ore comminution project was requiring a high pressure grinding roll to add in the existing three-stage crushing and ball milling process to form a customer required crushing system with capacity of 24000t/d. Compared to the previous crushing system of 14400t/d, the capacity of the system added with high pressure grinding roll (closed circuit dry screening) has been increased by 38.9% in output.

GM200-160 High Pressure Grinding RollThis 20,000,000t iron ore project adopts high pressure grinding roll with final grinding process. Due to the adoption of dry screening operation, the water consumption is greatly lowered. The cost of grinding separation and tailings conveying systems is significantly reduced. The machine capacity is 2200 t/h and the product size below 3mm is over 55%, fully satisfying the customer's expectations.

GM160-140 High Pressure Grinding RollIt was the first demonstration project of high pressure grinding roll in this location. The HPGR can help reduce feed particle size, Bond work index and steel consumption, while improving productivity and energy efficiency.

Manufacturing

Casting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively.

Lifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.

Links:https://www.globefindpro.com/products/4247.html

-

Power Transmission Belts

Power Transmission Belts

-

Spiral Notebooks

Spiral Notebooks

-

YX25-762 Roof Panel Roll Forming Machine

YX25-762 Roof Panel Roll Forming Machine

-

Flexo Printer Slotter

Flexo Printer Slotter

-

Liners

Liners

-

Electronics Prototyping

Electronics Prototyping

-

Softcover Notebooks, PU Leather Notebooks

Softcover Notebooks, PU Leather Notebooks

-

Patchwork Leather Notebooks

Patchwork Leather Notebooks

-

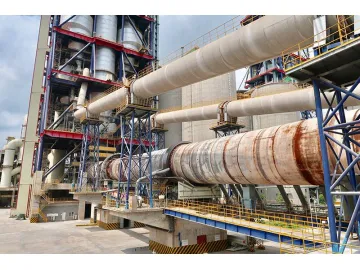

Rotary Kilns

Rotary Kilns

-

Conveyor Flat Belts

Conveyor Flat Belts

-

YX15/25-840/900 Double Layer Roll Forming Machine

YX15/25-840/900 Double Layer Roll Forming Machine

-

Vertical Stirred Mills

Vertical Stirred Mills