Hydrocarbon Dry Cleaning Machine

Rear

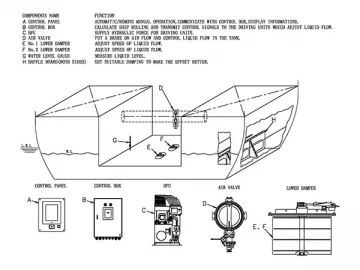

Profile (inside)

Based on years of culminating experience and techniques, we developed this multifunctional hydrocarbon dry cleaning machine which integrates washing, extracting, drying and distillation in a vacuum space.This easy-to-use commercial cleaning equipment is highly credited for its high-speed extraction of solvents and quick drying even under lower temperatures which also means less energy consumption.

Features of the Hydrocarbon Dry Cleaning Machine

1. Washing Circle: integrating washing, extracting, drying and distillation all together;

2. Multifunctional Computer Control: consisting of a large LCD color screen, user-friendly interface, self-checking malfunction device, and adjustable program settings depending on the type of textiles being washed;

3. Safe Working System: ensures safe operation as all washing, extracting, drying and distillation procedures are done in a vacuum condition;

4. Closed System: vacuum pump ensures industrial dry cleaning machine is fully closed;

5. Soft Mount Structure: suspension springs make it easy to attach any maintenance device or accessories to the machine;

6. Environmentally-Friendly Hydrocarbon Solvent: solvent is colorless, non-toxic, odorless, and eco-friendly;

7. Digital Frequency Conversion Technology: for stepless speed adjustment while washing, extracting and drying;

8. Gentle Cleaning: washing in a vacuum condition ensures that textiles are clean and free of residual air pollutants. The laundry equipment works especially well for furs, keeping them soft, silky and intact;

9. Efficient Filtration: solvent will be sprayed into a high-consistency filtration net for uniform filtering while the machine is running;

10. Special Cooling Reclaiming System: efficiently recycles solvents and keeps them under refrigeration status, helping reduce energy consumption;

11. Efficient Distillation System: removes neutral fats, mineral oils and pigments and ensures nothing is absorbed by used solvents, allowing the hydrocarbon solvent to remain pure for longer;

12. Solvent Tank: single or double solvent tank available.

Technical Specification of the Hydrocarbon Dry Cleaning Machine| MODEL NUMBER | Unit | K200FZQ | K300FZQ | K400FZQ |

| CAPACITY | ||||

| Dry Weight Capacity | kg/lbs | 10/22 | 15/33 | 20/44 |

| Drum Diameter | mm | 850 | 950 | 1200 |

| Drum Depth | mm | 300 | 432 | 390 |

| Loading Volume | dm3 | 170 | 306 | 441 |

| Under-Tank Volume | dm3 | 132 | 144 | 280 |

| Washing Speed | rpm | 42 | 40 | 32 |

| High Extract Speed | rpm | 930 | 900 | 800 |

| NYLON CENTRIFUGAL FILTER | ||||

| Filter Volume | dm3 | 30 | 55 | 69 |

| Filtration Capacity @1 bar | L/h | 4000 | 6000 | 7000 |

| Filtration Area | m2 | 2 | 4 | 5.5 |

| ELECTRICITY & POWER | ||||

| Power Supply | V/P/Hz | 380~415V, 3Phase, 50Hz | ||

| Main Motor | kW | 2.2 | 3.0 | 5.5 |

| Drying Motor | kW | 1.5 | 1.5 | 2.2 |

| Filtering Motor | kW | 1.1 | 1.1 | 1.5 |

| Vacuum Pump Motor | kW | 0.75 | 0.75 | 1.5 |

| Solvent Pump | kW | 1.1 | 1.5 | 1.5 |

| Maximum Load | kW | 6.65 | 7.85 | 12.2 |

| Cross Section Area of Circuit (copper) | mm2 | 5x4 | 5x4 | 5x6 |

| Current Capacity of Circuit | Amps | 35 | 35 | 50 |

| Actual Current | Amps | 14 | 16 | 20 |

| CONNECTIONS | ||||

| Compressed Air Pressure | MPa | 0.5~0.6 | 0.5~0.6 | 0.5~0.6 |

| Compressed Air Inlet | mm | ф6 | ф6 | ф6 |

| Water Pressure | MPa | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 |

| Water Inlet, Outlet | inch, mm | 1/2", DN15mm | 1/2", DN15mm | 1/2", DN15mm |

| Steam Pressure | MPa | 0.4~0.5 | 0.4~0.5 | 0.4~0.5 |

| Steam Inlet, Outlet | inch, mm | 1/2", DN15mm | 1/2", DN15mm | 1/2", DN15mm |

| CONSUMPTION | ||||

| Electricity, at 40 minutes of circulation | kW | 1.0 | 1.6 | 2.9 |

| Water, in case of the temp. of the water reaching 18℃ | L | 85.0 | 90.0 | 100.0 |

| Steam, at 150℃/0.5Mpa | kg | 3.8 | 4.0 | 6.5 |

| Compressed Air per cycle | L | 4.0 | 4.0 | 4.0 |

| DIMENSION | ||||

| Width/Depth/Height | mm | 1550/1350/2260 | 1690/1450/2350 | 2250/1650/2150 |

| Net Weight | kg | 650 | 1080 | 1800 |

Links:https://www.globefindpro.com/products/42547.html