Tooling for Wheel Spoke Manufacturing

Light weight, high strength and an attractive appearance have become the basic requirements for choosing passenger car wheels. High strength plates are also become popular materials for steel wheels. In order to accommodate fast and large scale production of automatic and efficient wheel disc production lines, manufacturers have higher requirements for the standardized production and the service life of the dies.

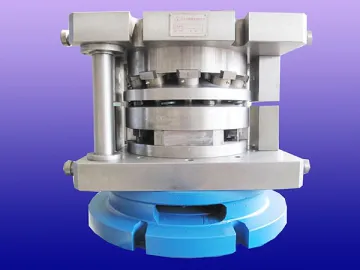

As a Chinese specialist designer and manufacturer of wheel production tooling, LittleDuck has developed tools and dies for high strength plate wheel spokes and disc manufacturing that are suitable for automatic wheel spoke stamping lines. According to the production process, there are 7 sets of dies in a complete wheel spoke profiling, punching and reshaping process. The specific dies are shown as follows.

Blanking-punching Compound Die

Pictures

3D Drawing

Samples

Forming Die

Pictures

3D Drawing

Samples

Trimming and Punching Die

Pictures

3D Drawing

Samples

Flanging Die

Pictures

3D Drawing

Samples

Piercing Die

Pictures

3D Drawing

Samples

Vent Hole Deburring Tool

Pictures

3D Drawing

Samples

Bolt Hole Deburring Tool

Pictures

3D Drawing

Samples

2. Stand Alone Series

To meet the requirements of traditional wheel disc production lines for standalone operation, we conduct specific process design and die structure design. Generally, traditional wheel disc production is carried out in 9 processes: blanking-punching, initial drawing, profiling, trimming and punching, flanging, screw hole punching, screw hole deburring, air hole punching, and air hole deburring. Each process uses a specific die, some of which are listed below.

Air hole punching die

Screw hole punching die

Forming die

Profiling die

Compound punching die

Pressing die

Links:https://www.globefindpro.com/products/42588.html

-

ERW Steel Pipe

ERW Steel Pipe

-

Marine Furniture

Marine Furniture

-

Sprinkler Parts (Nelson Sprinkler 3000 Series)

Sprinkler Parts (Nelson Sprinkler 3000 Series)

-

Angle and Truss Rod (Hot Dip Galvanized Steel)

Angle and Truss Rod (Hot Dip Galvanized Steel)

-

Self-Propelled Irrigation System (Drivable Mobile Pivot)

Self-Propelled Irrigation System (Drivable Mobile Pivot)

-

Lateral Move System (Ditch Feed)

Lateral Move System (Ditch Feed)

-

Trimmer, Planisher, End Cutting Machine

Trimmer, Planisher, End Cutting Machine

-

Windlass

Windlass

-

Flash Butt Welding Machine

Flash Butt Welding Machine

-

Anchor Handling / Towing Winch

Anchor Handling / Towing Winch

-

Pivot Tire (Rubber)

Pivot Tire (Rubber)

-

Stamping Tools

Stamping Tools