Chemical Injection Pump

Main Specifications

1) Capacity of 85 to 500 LPH

2) Maximum pressure up to 12 bar

3) Measuring accuracy of /- 2%

4) Between 10% - 100% flow rate

5) Temperatures of liquid between -10oC - 40oC

6) Maximum suction of 2m

7) Motor: Standard 220V/380V, 50HZ

Features

1) Mechanical Actuated Diaphragm

2) Changeable eccentric drive

3) Power-off seal, no leakage

4) Security delivery device

5) Compact and simple structure that’s easy to maintain

Control System

1) Manual adjustment of strokes

2) Stroke actuator

3) Digital controller

Other Advantages

1. The chemical injection pump, or called chemical dosing pump can transport chemicals that are high-viscosity, corrosive or dangerous. The diaphragm rupture detection system will identify any problem areas that could affect the work of the irrigation pump.

2. Injection quills deposit chemicals near the center of the line where the flow is largest, providing more uniform dispersion.

4. Back pressure ensures metering accuracy.

5. The chemical injection pump prevents back flow and leaking when water pressure is low or the line is drained.

6. Prevents siphoning when metering the chemigation pump.

7. Chemicals are sprayed evenly with quills.

8. The scale on the tank makes applying chemicals convenient and fast. After adding the appropriate amount of chemicals, the mixer works with them to create the right concentration.

9. The tank made from HDPE is highly corrosion-resistant, strong and reliable.

10. The tank body is seamless and well-designed. The inlet is tightly sealed and effectively prevents accidents resulting in harm to children or livestock. Technical Parameters of Chemical Injection Pump

| Flow (L/h) | Pressure (Mpa) | Pump Speed (SPM) | Stroke Motor (mm) | Diaphragm Effective Diameter (mm) | Worm Gear Speed Ratio | Electric Motor Chosen | Diameter of inlet & Outlet Pump Pipes (mm) |

| 85 | 0.7 | 72 | 6 | 70 | 20:1 | 3-50HZ 220/380V IP55/F | DN15 DN25 |

| 120 | 72 | 8 | |||||

| 170 | 144 | 6 | 10:1 | ||||

| 240 | 144 | 8 | |||||

| 315 | 0.5 | 144 | 8 | 80 | |||

| 400 | 144 | 10 | |||||

| 500 | 180 | 8:1(m2.5,24:3) |

Links:https://www.globefindpro.com/products/42609.html

-

Sprinkler Parts (Senninger Sprinkler UP3)

Sprinkler Parts (Senninger Sprinkler UP3)

-

PANDORA Series

PANDORA Series

-

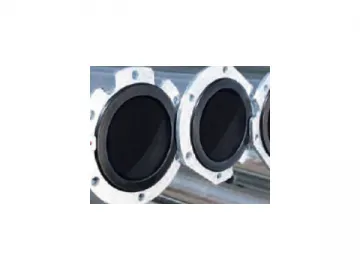

Irrigation Pipe (Hot Dip Galvanized Steel)

Irrigation Pipe (Hot Dip Galvanized Steel)

-

Center Pivot Irrigation System (Towable Pivot)

Center Pivot Irrigation System (Towable Pivot)

-

YOGA Mannequin

YOGA Mannequin

-

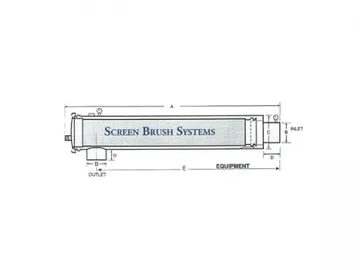

Irrigation Filter

Irrigation Filter

-

Center Pivot Irrigation System (Fixed Pivot)

Center Pivot Irrigation System (Fixed Pivot)

-

DAISY Series

DAISY Series

-

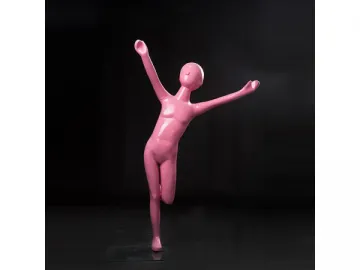

Abstract Child Mannequin

Abstract Child Mannequin

-

Gooseneck (Hot Dip Galvanized Steel)

Gooseneck (Hot Dip Galvanized Steel)

-

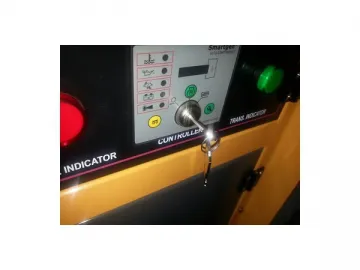

Diesel Generator

Diesel Generator

-

Realistic Male Mannequin

Realistic Male Mannequin