Rotary Abrasion Tester

The rotary abrasion tester, commonly referred to as Taber abraser or Taber abrader, is a popular set of testing equipment for evaluating the wear resistance of a wide spectrum of materials, including fabrics, coatings, laminates, leather, paper, glass, carpeting, ceramics, natural rubber, etc.

Working Principle of the Rotary Abrasion Tester

Our Taber rotary abraser sets a specimen onto a turntable platform first, and then two abrading wheels, which are applied at a specific pressure, are lowered onto the surface of specimen. As the turntable rotates, the wheels are driven by the sample in opposite directions about a horizontal axis so as to abrade the specimen.

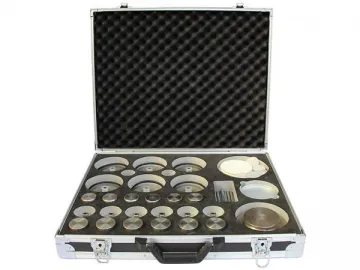

Standard Accessories of the Rotary Abrasion Tester

The Taber abraser is supplied with a full range of auxiliary weights, specimen holders, abrasive wheels, wheel refacer and vacuum unit.

Standard

ASTM D3884, ISO 5470

1. Abrasive wheels: H-18

2. Center distance between wheels: 63.5mm

3. Center distance between wheel and specimen holder: 37-38mm

4. Rotational speed of turntable: 60-72 rpm

5. Abrasive wheel movement track: 31/2" OD and 21/2" ID (covering an area of 30mm2)

6. Auxiliary weight: 250g, 750g

7. Counter: LCD, 0-999,999 times

1. Specimen size: 120mm OD, 6.5mm ID, 3mm thick

2. Abrasive wheel size: Ф2"×1/2"

3. Center distance between wheels: 52.4mm

4. Center distance between wheel and specimen holder: 19.1mm

5. Rotational speed of turntable: 60-72 rpm

6. Abrasive wheel movement track: 3" OD and 2" ID (covering an area of 25mm2)

7. Auxiliary weight: 250g, 500g, 1000g

8. Counter: LCD, 0-999,999 times

9. Distance between specimen and pick-up nozzle: 3mm (adjustable)

10. Dimensions: Approx. 44×37×27cm

11. Weight: Approx. 18kg

Links:https://www.globefindpro.com/products/43188.html

-

Pilling and Snagging Resistance Tester

Pilling and Snagging Resistance Tester

-

Bursting Strength Testing Machine

Bursting Strength Testing Machine

-

Durability Testing Machine (Toy Box Lid Tester)

Durability Testing Machine (Toy Box Lid Tester)

-

Thermal Insulation Test Apparatus

Thermal Insulation Test Apparatus

-

Footwear Testing Machine (Stiffness Tester for Insole Fittings)

Footwear Testing Machine (Stiffness Tester for Insole Fittings)

-

Compression and Rebound Tester

Compression and Rebound Tester

-

Whole Shoes Flexing Tester

Whole Shoes Flexing Tester

-

Abrasion and Pilling Resistance Testing Machine (Martindale Abrasion Tester)

Abrasion and Pilling Resistance Testing Machine (Martindale Abrasion Tester)

-

Seam Fatigue Tester

Seam Fatigue Tester

-

Abrasion and Pilling Resistance Testing Machine (Nu-Martindale Abrasion Tester)

Abrasion and Pilling Resistance Testing Machine (Nu-Martindale Abrasion Tester)

-

Pilling Resistance Testing Machine

Pilling Resistance Testing Machine

-

Durability Testing Machine (Small Toy Choke Tester)

Durability Testing Machine (Small Toy Choke Tester)