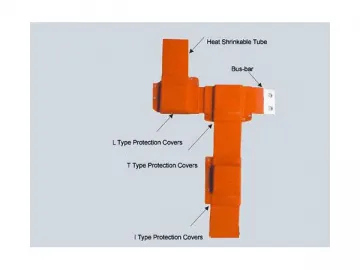

Heat Shrink Tubing (Insulated Tubing for 40.5kV Busbar)

Introduction of Insulated Tubing for 40.5kV Busbar

The heat shrink tubing is made by bombarding crosslinked polyolefin heat shrinkable material with high-energy electron beam, and environmentally harmful substances such as PBB, PBBD, PBBE and heavy metals are restricted. When burned, the heat shrink tubing does not generate poisonous gas or hazardous substances, and the heat shrink sleeve can provide high dielectric strength and track resistance. Our heat shrink tubing is a certified product, and can be applied to corrosion protection and insulation of busbar and electrical equipment.

Model List

MPG5-40.5 Insulated Tubing for 40.5kV Busbar

| Product | Specification | Applicable square busbar width(mm) | Applicable round busbar width(mm) | Before shrink dimensions (mm) | After shrink dimensions (mm) | Standard Package | ||

| inner diameter | wall thickness | inner diameter | wall thickness | meters / roll | ||||

| MPG5-40.5- φ 30 | 30/12 | 30 | 20 | 30 | 2.00 | ≤13 | 4.00±0.30 | according to customer requirements |

| MPG5-40.5- φ 40 | 40/16 | 40 | 30 | 40 | 2.00 | ≤16 | 4.00±0.30 | according to customer requirements |

| MPG5-40.5- φ 50 | 50/22 | 50 | 35 | 50 | 2.00 | ≤22 | 4.00±0.30 | according to customer requirements |

| MPG5-40.5- φ 60 | 60/25 | 60 | 40 | 60 | 2.30 | ≤28 | 4.00±0.30 | according to customer requirements |

| MPG5-40.5- φ 70 | 70/26 | 70 | 50 | 70 | 2.00 | ≤28 | 4.00±0.30 | according to customer requirements |

| MPG5-40.5- φ 80 | 80/33 | 80 | 60 | 80 | 2.30 | ≤35 | 4.20±0.30 | according to customer requirements |

| MPG5-40.5- φ 90 | 90/35 | 90 | 65 | 90 | 2.00 | ≤35 | 4.20±0.30 | according to customer requirements |

| MPG5-40.5- φ 100 | 100/38 | 100 | 70 | 100 | 2.30 | ≤40 | 4.50±0.30 | according to customer requirements |

| MPG5-40.5- φ 120 | 120/44 | 120 | 85 | 120 | 2.00 | ≤44 | 4.50±0.30 | according to customer requirements |

| MPG5-40.5- φ 140 | 140/50 | 150 | 115 | 140 | 2.30 | ≤49 | 4.50±0.30 | according to customer requirements |

| MPG5-40.5- φ 160 | 160/66 | 160 | 125 | 160 | 2.50 | ≤66 | 4.50±0.30 | according to customer requirements |

| MPG5-40.5- φ 200 | 200/80 | 200 | 140 | 200 | 2.50 | ≤80 | 4.50±0.30 | according to customer requirements |

| Color: iron red, yellow, green, or any other color according to customer requirements | ||||||||

Features of Insulated Tubing for 40.5kV Busbar

Shrink proportion: 2:1 (1kV, 40.5kV), 2.5:1 (12kV busbar)

Shrink temperature: 84 ℃ ~ 125 ℃

Working temperature: -40 ℃ ~ 125 ℃

Our bus bar heat shrink tubing is eenvironmentally friendly, high strength, flexible, flame retardant, and soft.

Applications of Insulated Tubing for 40.5kV Busbar

Function: the bus bar heat shrink tubing can be used for electrical insulation, mechanical protection, reducing phase spacing and making connector box.Applicable area: power industry

Standard Compliance of Insulated Tubing for 40.5kV Busbar

GB / T 1059-2007

Environmental certification: RoHS

Standard color: red, yellow, green, black, blue

Parameters of Insulated Tubing for 40.5kV Busbar

| Performance | Unit | Performance Standard | Test Method / Condition |

| Tensile strength | MPa | ≥10.4 (before aging) | GB/T 1040 130 ℃ ×168h |

| ≥7.3 (after aging) | |||

| Elongation | % | ≥300 (before aging) | GB/T 1040 , GB/T7141 130 ℃ ×168h |

| ≥100 (after aging) | |||

| Heat shock | - | No sticky, no cracks | JB 7829 appendix D. ( 160 ℃ ×4h ) |

| Chilling bending | - | No cracks | -30 ℃ ×4h |

| Breakdown strength | kv/mm | ≥25 | GB/T 1408.1 |

| Volume resistivity | Ω.cm | ≥1×10 14 | GB/T 1410 |

| Radial shrinkage | % | ≥50 | |

| Eccentricity ** | % | ≤30 | UL 224 |

| Fire retardancy | - | ≥30 | GD/T 2406 |

| Water absorption | % | ≤0.5 | ISO 62-1980 |

| Power frequency withstand voltage * | kv/mm | ≥30kV.1min | GB/T 1408.1 |

| Shore hardness (Shore A) | ≤90 | GB 2401 |

We are a professional power distribution equipment manufacturer and supplier in China. To find the best power distribution solutions, just find us!

Links:https://www.globefindpro.com/products/43258.html

-

Terminal Block

Terminal Block

-

Footwear Water Resistance Testing Machine

Footwear Water Resistance Testing Machine

-

Insulating Bushing

Insulating Bushing

-

Embedded Pole (Insulating Pole for 24kV Electrical Distribution System)

Embedded Pole (Insulating Pole for 24kV Electrical Distribution System)

-

Vacuum Circuit Breaker (TZN1 Indoor High Voltage Circuit Breaker)

Vacuum Circuit Breaker (TZN1 Indoor High Voltage Circuit Breaker)

-

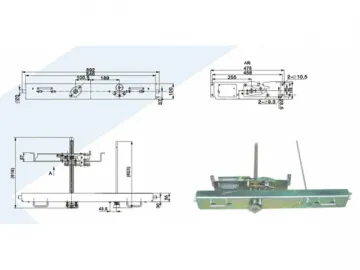

Racking Mechanism (Racking Mechanism for 40.5KV Switchgear)

Racking Mechanism (Racking Mechanism for 40.5KV Switchgear)

-

Indicating Device for Switchgear

Indicating Device for Switchgear

-

Heat Shrink Tubing(Insulated Cover for Busbar)

Heat Shrink Tubing(Insulated Cover for Busbar)

-

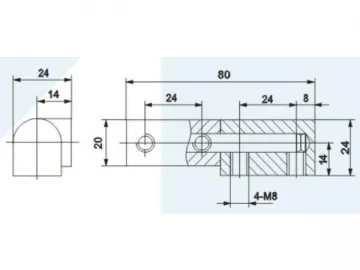

Switchgear Hinge

Switchgear Hinge

-

Water Resistance Testing Machine (Hydrostatic Head Tester)

Water Resistance Testing Machine (Hydrostatic Head Tester)

-

Electrical Conductor (PT Electrical Contact Arm)

Electrical Conductor (PT Electrical Contact Arm)

-

Light Discoloration Testing Chamber

Light Discoloration Testing Chamber