Oil-injected Screw Compressor, EVO Series

with German Screw Air End with German Screw Air End  Request a quote Power 5.5-132kW

Request a quote Power 5.5-132kW

Working pressure 8-15bar

Free air delivery 0.53-23.08m³/min

EVO Series Advantages Specifications Why Using Rotorcomp EVO Series Screw Air End

Reduced internal leakage;

Thermally optimized oil injection system;

Improved suction port efficiency giving reduced internal losses; Low power consumption due to:

Optimized torque characteristics and reduced internal friction;

Improved outlet port with lower pressure losses; Reduced noise and low vibration due to:

Smooth rolling of the rotors with new ROLLING PROFILE®;

Optimized outlet port; Advantages of Oil-injected Screw Compressor Screw air end from world's leading manufacturer – Rotorcomp; Excellent cooling system, the heat dissipation is increased by 20-30% in comparison with conventional versions; Advanced intelligent control system with color touch screen, making operation easier; Equipped with energy saving electric motor (SF=1.2, IP55, IE3 CE&MEPS), increasing 15% of efficiency; Exclusive driving guard system, extending the service life of transmission system; Schneider electrical components are used, enabling the screw air compressor to be used in a harsh environment with reliable operation; Patented OPTI belt transmission, the belt is tensioned through the action of starting torque and motor weight; The design service life can reach 25000 hours and transmission efficiency is 98% and above; Technical Specifications

Tags: screw compressor blocks compressor packages oil-injected air ends OEM supplier of compressor compressor for nitrogen generation

EVO series oil-injected screw compressor was designed with high-efficiency and quieter operation in mind. This rotary screw compressor adopts Rotorcomp screw air end that has the most highly regarded quality label "Made in Germany". The unique design of the air compressor provides greater energy efficiency and higher stability, which are certified in accordance with ISO, TUV, GA and SGS standards. This oil-injected screw compressor is offered with a standard 2-year warranty, and the screw air end is covered by a 5-year warranty.

Working pressure 8-15bar

Free air delivery 0.53-23.08m³/min

EVO Series Advantages Specifications Why Using Rotorcomp EVO Series Screw Air End

Advantages of EVO® Technology

New ROLLING PROFILE®, ultimate efficiency and reduced noise; Long life cycle due to generous bearing dimensions and wear-free ROLLING PROFILE®; Wide working pressure range, from 5 to 15 bar; High quality manufacturing and assembling –"Made in Germany"; Quality assurance, bench test of every air end before leaving factory; Easy application selection with our new ROTORCOMP® SIZING AIR software; Highest flexibility for your package design; Suitable for all types of drive motors;Ultimate Efficiency and Reduced Noise

High volumetric output due to:Reduced internal leakage;

Thermally optimized oil injection system;

Improved suction port efficiency giving reduced internal losses; Low power consumption due to:

Optimized torque characteristics and reduced internal friction;

Improved outlet port with lower pressure losses; Reduced noise and low vibration due to:

Smooth rolling of the rotors with new ROLLING PROFILE®;

Optimized outlet port; Advantages of Oil-injected Screw Compressor Screw air end from world's leading manufacturer – Rotorcomp; Excellent cooling system, the heat dissipation is increased by 20-30% in comparison with conventional versions; Advanced intelligent control system with color touch screen, making operation easier; Equipped with energy saving electric motor (SF=1.2, IP55, IE3 CE&MEPS), increasing 15% of efficiency; Exclusive driving guard system, extending the service life of transmission system; Schneider electrical components are used, enabling the screw air compressor to be used in a harsh environment with reliable operation; Patented OPTI belt transmission, the belt is tensioned through the action of starting torque and motor weight; The design service life can reach 25000 hours and transmission efficiency is 98% and above; Technical Specifications

| Model | Capacity (m3/min)* | Power (kW) | Inlet/Outlet | Noise Level | Dimension | Weight | ||||

| 8bar | 10bar | 13bar | 15bar | Motor | Motor (Fan) | dB(A)** | L×W×H in mm | kg | ||

| LGFD-5.5 | 0.87 | 0.75 | 0.61 | 0.53 | 5.5 | 0.09 | G1 | 69 | 900×750×900 | 245 |

| LGFD-7.5 | 1.2 | 1.04 | 0.9 | 0.8 | 7.5 | 0.09 | G1 | 69 | 900×750×900 | 250 |

| LGFD-11 | 1.79 | 1.58 | 1.32 | 1.17 | 11 | 0.18 | G1 | 70 | 950×800×1290 | 370 |

| LGFD-15 | 2.4 | 2.15 | 1.84 | 1.66 | 15 | 0.18 | G1 | 70 | 950×800×1290 | 480 |

| LGFD-18.5 | 3 | 2.9 | 2.52 | 2.02 | 18.5 | 0.37 | G1 | 71 | 1250×960×1300 | 730 |

| LGFD-22 | 3.51 | 3.16 | 2.71 | 2.45 | 22 | 0.37 | G1 | 71 | 1250×960×1300 | 750 |

| LGFD-30 | 4.88 | 4.32 | 3.64 | 3.25 | 30 | 0.75 | G1-1/4 | 71 | 1440×1006×1296 | 1200 |

| LGFD-37 | 5.83 | 5.21 | 4.44 | 4.01 | 37 | 0.75 | G1-1/4 | 73 | 1440×1006×1296 | 1350 |

| LGFD-45 | 7.08 | 6.3 | 5.43 | 4.94 | 45 | 1.1 | G1-1/4 | 75 | 1440×1006×1296 | 1400 |

| LGFD-55 | 9.32 | 8.33 | 7.05 | 6.31 | 55 | 1.1 | G2 | 75 | 1600×1200×1650 | 1600 |

| LGFD-75 | 12.31 | 11.13 | 9.61 | 8.74 | 75 | 1.1 | G2 | 75 | 1600×1200×1650 | 1750 |

| LGFD-90 | 16.45 | 14.26 | 11.72 | 10.8 | 90 | 2.2 | G2 | 75 | 2000×1580×1790 | 2600 |

| LGFD-132 | 20.26 | 17.48 | 14.25 | 13.05 | 110 | 2.2 | G2 | 78 | 2500×1700×1900 | 3000 |

| LGFD-180 | 23.08 | 20.54 | 17.65 | 16.05 | 132 | 2.2 | G2 | 78 | 2500×1700×1900 | 3150 |

Scan QR to Read

Links:https://www.globefindpro.com/products/4331.html

Links:https://www.globefindpro.com/products/4331.html

Recommended Products

-

PM-VSD Rotary Screw Compressor, VP Series

PM-VSD Rotary Screw Compressor, VP Series

-

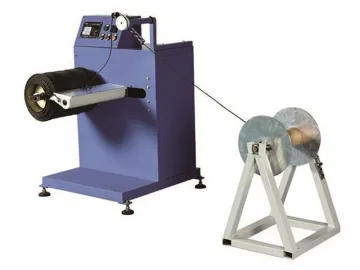

Paper Rope Rewinding Machine XKFJ-400M

Paper Rope Rewinding Machine XKFJ-400M

-

Oil-free Scroll Compressor

Oil-free Scroll Compressor

-

WELD-2000HP Handheld Laser Welder

WELD-2000HP Handheld Laser Welder

-

Paper Bag Making Machine for Block Bottom Bag with Window

Paper Bag Making Machine for Block Bottom Bag with Window

-

Paper Bag Making Machine for Self Opening Sack Production

Paper Bag Making Machine for Self Opening Sack Production

-

Twisted Paper Rope Making Machine

Twisted Paper Rope Making Machine

-

Automatic Flat Handle Making Machine XKBS-01

Automatic Flat Handle Making Machine XKBS-01

-

4 Color Flexo Printing Machine XKFP-4 Colors

4 Color Flexo Printing Machine XKFP-4 Colors

-

Direct Drive Rotary Screw Compressor, LGCD Series

Direct Drive Rotary Screw Compressor, LGCD Series

-

Portable Breathing Air Compressor

Portable Breathing Air Compressor

-

2 Color Flexo Printing Machine XKFP-2 Colors

2 Color Flexo Printing Machine XKFP-2 Colors

Hot Products