Ceramic Rollers for Galvanizing Bath

Though the ceramic rollers for galvanizing bath has better performance, most companies in the steel wire galvanizing industry use low carbon steel rollers (05F~08F) for galvanizing bath. As important parts for galvanizing line, when the low carbon steel rollers stay in the high temperature melted zinc for a long time, they will get seriously corroded. Accordingly, the galvanizing performance will also decrese.

The service life of a typical low carbon roller is about 3-5 years, and frequent production halts are needed for maintenance. So we decided to develop better rollers for galvanizing. The silicon nitride and silicon carbide are adopted to improve the anti-corrosion performance and service life. By rigid calculation and dynamic simulation designing, our ceramic rollers for galvanizing bath comes in a curved circular sector shape, meeting all the requirements of vertical wire lifting technique and inclined wire lifting technique for bending radius. The advancing resistance to the steel wire is also reduced. The trough design on the circular sector surface can guarantee the the stability during the wire moving.

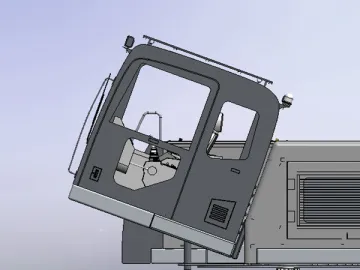

Transmission device of the ceramic rollers

Common ceramic rollers made of fireproofing material

Common ceramic rollers made of fireproofing material

Parameter of the ceramic rollers for galvanizing bath

Material: silicon nitride and silicon carbide Wire diameter: 1.6~8.0mm Wire number: 6~40 wires Wire interval: 25~60mm Service life: 2~4 yearsLinks:https://www.globefindpro.com/products/43505.html

-

Centrifuge Machines for Fastener Galvanizing

Centrifuge Machines for Fastener Galvanizing

-

SMQ250A Telescopic Crawler Crane

SMQ250A Telescopic Crawler Crane

-

Gas Fired Ceramic Immersion Heaters for Hot Dip Galvanizing

Gas Fired Ceramic Immersion Heaters for Hot Dip Galvanizing

-

PAUT/AUT Bottom Discharge Scraper Centrifuges with Top Mounted Motor

PAUT/AUT Bottom Discharge Scraper Centrifuges with Top Mounted Motor

-

Electric Ceramic Immersion Heaters for Hot Dip Galvanizing

Electric Ceramic Immersion Heaters for Hot Dip Galvanizing

-

Steel Wire Hot-Dip Galfan Coating Line (Galfan® coated steel wire production line)

Steel Wire Hot-Dip Galfan Coating Line (Galfan® coated steel wire production line)

-

Galfan Coated Steel Wire

Galfan Coated Steel Wire

-

Steel Wire Electro Galvanizing Line

Steel Wire Electro Galvanizing Line

-

SMQ750A Telescopic Crawler Crane

SMQ750A Telescopic Crawler Crane

-

Acid & Alkali Resistant Fluid Heaters

Acid & Alkali Resistant Fluid Heaters

-

Zinc Corrosion Resistant Thermocouples

Zinc Corrosion Resistant Thermocouples

-

Electromagnetic Field and Gas Wiping Equipment for Steel Wire Hot-Dip Galvanizing Lines

Electromagnetic Field and Gas Wiping Equipment for Steel Wire Hot-Dip Galvanizing Lines