Inconel 600 Nickel Alloy

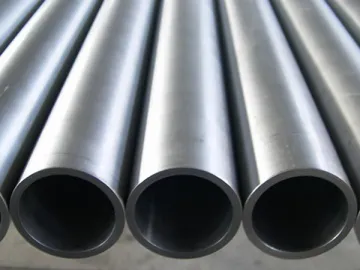

The Inconel 600 nickel alloy, a solid solution strengthened alloy with nickel, chrome and iron as principal elements, is a standard engineering material suitable for heat resistant and corrosion resistant applications. Owing to excellent mechanical property and strength as well as great cold and hot processing and welding performance, this nickel-chromium-iron alloy obtains high praise and recognition in various industries.

The Inconel alloy 600 features high universality, enabling it to perform perfectly in various applications in which the temperature ranges from very low level to over 1095℃. In addition, this type of high temperature alloy comes with high strength and oxidation resistance that offer it satisfactory heat resistance and high plasticity under 700℃.

The Inconel 600 nickel alloy is widely used in the heater, distiller and condenser in fatty acid process, rolling furnace wall, furnace components and tray in heat treatment industry, and abietic acid processing equipment in paper pulp manufacturing.

Specifications| UNS | W. Nr |

| N06600 | 2.4816 |

| Alloy 600 | Ni | Cr | Fe | C | Mn | Si | Cu | P | S | |

| Content (%) | Min | 72 | 14 | 6 | ||||||

| Max | 17 | 10 | 0.15 | 1 | 0.5 | 0.5 | 0.015 | 0.015 | ||

Mechanical Properties (Minimum value at 20℃)

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 585 | 240 | 30 |

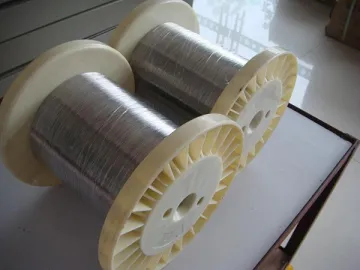

Product Forms and Standards of Inconel 600 Nickel Alloy

| Bar | Forging | Sheet/Strip | Wire | Pipe |

| ASTM B166 | ASTM B366 | ASTM B168 | ASTM B166 | ASTM B167 ASTM B163 ASTM B516 ASTM B517 |

Links:https://www.globefindpro.com/products/43876.html

-

Alloy 20 Nickel Alloy

Alloy 20 Nickel Alloy

-

Monel 400 Nickel Alloy

Monel 400 Nickel Alloy

-

Inconel 625 Nickel Alloy

Inconel 625 Nickel Alloy

-

Integrated Vacuum Degreasing and Sintering Furnace

Integrated Vacuum Degreasing and Sintering Furnace

-

EQNiCr-3 Nickel Alloy Welding Strip

EQNiCr-3 Nickel Alloy Welding Strip

-

ERNiCu-7 Nickel Alloy Welding Wire

ERNiCu-7 Nickel Alloy Welding Wire

-

Vacuum Induction Melting Furnace

Vacuum Induction Melting Furnace

-

ERNiFeCr-1 Nickel Alloy Welding Wire

ERNiFeCr-1 Nickel Alloy Welding Wire

-

Inconel 718 Nickel Alloy

Inconel 718 Nickel Alloy

-

Vertical Dryer

Vertical Dryer

-

MH Series High Head Slurry Pump

MH Series High Head Slurry Pump

-

Drum Dryer for Gypsum

Drum Dryer for Gypsum