Incoloy 825 Nickel Alloy

The Incoloy 825 nickel alloy has excellent resistance to stress corrosion cracking and to pitting and crevice corrosion. In addition, the Incoloy alloy 825 is especially resistant to reducing and oxidizing acids such as sulfuric acid, phosphoric acid and nitric acid, to organic acid, to alkalis including NaOH and KOH, and to hydrochloric acid.

The resistance of the nickel-iron-chromium alloy 825 to general and localized corrosion under diverse environments gives it unexpected usefulness. Applications include chemical processing and pollution control equipment, oil and gas well pipe, nuclear fuel recovery and pickling operation facilities.

Specification of Incoloy 825 Nickel Alloy| UNS | W. Nr |

| N08825 | 2.4858 |

Chemical Compositions

| Composition | Ni | Cr | Fe | C | Mn | Si | Cu | Mo | Al | Ti | P | S | |

| Content (%) | Min. | 38 | 19.5 | Bal. | 1.5 | 2.5 | 0.6 | ||||||

| Max. | 46 | 23.5 | 0.05 | 1 | 0.5 | 3 | 3.5 | 0.2 | 1.2 | 0.03 | 0.03 | ||

Mechanical Properties (Minimum value at 20℃)

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 550 | 220 | 30 |

Product Forms and Standards

| Bar | Forging | Sheet/Strip | Wire | Pipe |

| ASTM B408 | ASTM B564 | ASTM B409 | ASTM B408 | ASTM B407 ASTM B514 |

Scan QR to Read

Links:https://www.globefindpro.com/products/43901.html

Links:https://www.globefindpro.com/products/43901.html

Recommended Products

-

Incoloy 800 Nickel Alloy

Incoloy 800 Nickel Alloy

-

Gas Atomization Powder Manufacturing Equipment

Gas Atomization Powder Manufacturing Equipment

-

Inconel 690 Nickel Alloy

Inconel 690 Nickel Alloy

-

Rotary Furnace

Rotary Furnace

-

PSA Nitrogen Generator

PSA Nitrogen Generator

-

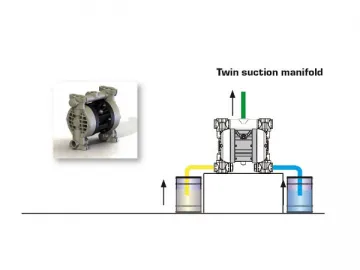

QBK Air Operated Diaphragm Pump

QBK Air Operated Diaphragm Pump

-

Incoloy 800H Nickel Alloy

Incoloy 800H Nickel Alloy

-

Amorphous Alloy Powder Equipment

Amorphous Alloy Powder Equipment

-

Invar 36 Nickel Alloy

Invar 36 Nickel Alloy

-

Iron-Chromium-Aluminium Alloy for Electrical Resistance Heating

Iron-Chromium-Aluminium Alloy for Electrical Resistance Heating

-

Inconel 601 Nickel Alloy

Inconel 601 Nickel Alloy

-

Inconel X-750 Nickel Alloy

Inconel X-750 Nickel Alloy

Hot Products