Rotary Furnace

EasyFashion rotary furnace is economically engineered for reduction, dry and calcination of metal powders, in particular calcination and reduction of APT and ammonium tungstate. Our metal powder equipment comprises feeding unit, discharging unit, rotating unit and dynamic sealing unit, as well as exhauster and dust collector, etc.

Material’s time in rotary kiln is determined by the adjustment on rotating speed, inclination and feeding speed. Chemical atmosphere inside this calcination furnace falls into hydrogen, ammonia gas and air on the basis of different application needs. Positive pressure is maintain inside furnace tube, and is adjustable to cater to gas charging.

Advantage

1. Sealing unit of our rotary furnace comes with well-conceived design. Chemical atmosphere pressure is adjustable.

2. Heating unit is optimally deployed for convenient maintenance. Thanks to uniformed heating effect, output product is endowed with stable quality.

3. Proper vibrating device is available on this reduction furnace to prevent residuals in furnace.

4. Automatic feeding and discharging units ensure continuous production. Astonishing mechanization delivers amazing production capacity.

5. Intuitive display facilitates ease of operation.

Technical data| Model | EF-RL300 | EF-RL400 |

| Power (kW) | 60-70 | 80-95 |

| Production capacity (t/day) | 1-1.5 | 3-3.5 |

| Rotation speed | 1-8rpm | 1-8rpm |

| Number of temperature control zone | 2 | 3 |

| Angle of inclination | 3-6 | 3-6 |

| Working temperature | 600-700 | 600-700 |

| Max. temperature | 850 | 850 |

| Powder recovery rate (%) | 95-97 | 95-97 |

| Furnace weight (kg) | 5600 | 8900 |

| Overall dimension (L × W × H) | 7100 × 1730 × 2570 | 10000 × 1830 × 3280 |

Note

Non-standard rotary furnace is available in accordance with your requirements.

Supporting Equipment Vacuum Induction Melting Furnace Vacuum Brazing Furnace Nitrogen/Hydrogen Generator by Ammonia Decomposition

Related Names

Rotary Hearth Machine | Rotating Furnace | Rotary Calcining Kiln

Links:https://www.globefindpro.com/products/43905.html

-

PSA Nitrogen Generator

PSA Nitrogen Generator

-

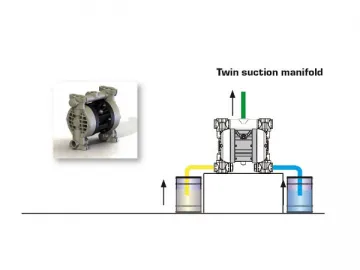

QBK Air Operated Diaphragm Pump

QBK Air Operated Diaphragm Pump

-

QBY Air Operated Diaphragm Pump

QBY Air Operated Diaphragm Pump

-

Dual-chamber Vacuum Oil Quenching Furnace

Dual-chamber Vacuum Oil Quenching Furnace

-

Vacuum Degreasing Furnace

Vacuum Degreasing Furnace

-

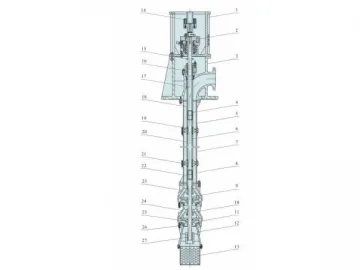

Vertical Turbine Pump

Vertical Turbine Pump

-

Inconel 690 Nickel Alloy

Inconel 690 Nickel Alloy

-

Gas Atomization Powder Manufacturing Equipment

Gas Atomization Powder Manufacturing Equipment

-

Incoloy 800 Nickel Alloy

Incoloy 800 Nickel Alloy

-

Incoloy 825 Nickel Alloy

Incoloy 825 Nickel Alloy

-

Incoloy 800H Nickel Alloy

Incoloy 800H Nickel Alloy

-

Amorphous Alloy Powder Equipment

Amorphous Alloy Powder Equipment