CNC Platen Type Plasma Cutting Table

Description

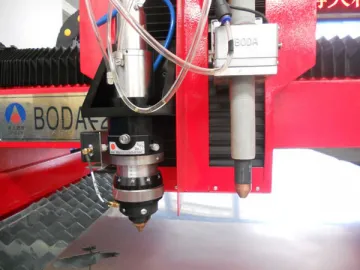

If you need a highly precision plasma cutting table, we recommend our CNC platen type plasma cutting machine to you. This machine is mainly used for cutting thin (0.3-2 mm) plates. The maximum working width and length is 2×7 m, and the idle running speed reaches 12,000 mm/min. When the machine is working, the platen of the platen type height controller presses against the steel plate, keeping a constant distance between the cutting torch and the plate. Thus the cutting performance especially the precision is improved.

This type of CNC platen cutting equipment could come with Kjellberg laser class plasma generator from Germany, and accurate Lantek nesting software from Spanish, contributing to highly precision cutting performance. Many pipe manufacturers view these accessories as their preferential choice.

Advantage

1. The CNC platen type plasma cutting table has been awarded the "hi-tech product of Jiangsu province" certificate.

2. Integrated structure.

The transverse and longitudinal rails and the cutting station are in one piece, making the moving operation quite convenient. When the equipment has arrived clients’ workshop, all you need to do is get the power ready to make it work. Additional machine platform and cutting table are not needed. The installation and operation is both very simple.

3. Special platen design.

When the CNC platen type plasma cutting table is working, the platen will press against the steel plate to maintain a certain distance between the cutting torch and the steel plate. This CNC platen type plasma cutter is typically for those plates with a thickness of 0.3-2 mm. The cutting performance is quite great. Specifically, the cutting edge is really smooth.

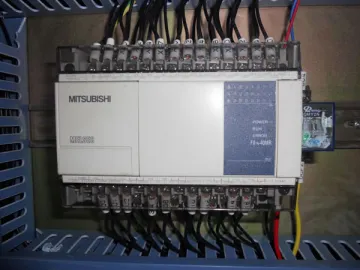

4. Mitsubishi PLC.

Mitsubishi is one of the leaders in the small PLC industry. The control functions are powerful. As the logic control center, PLC processes all the logic signals of the control system. Besides, we have more than ten years of cutting control experience, so the PLC has complete functions for various of cutting techniques, as well as prevent the signal disturbance.

5. Improved earthing system.

It has great anti-interference performance, ensuring that the CNC platen type plasma cutting table can work stably for a long time.

6. Specially designed dust collecting system.

The built-in dust collecting hole in the bottom of the cutting table, together with the well closed dust collecting chamber, can facilitate the installation of dust collecting system.

Machine parameter

| Transverse rail interval | 1500-2500 mm |

| Effective cutting width | 1000-2000 mm |

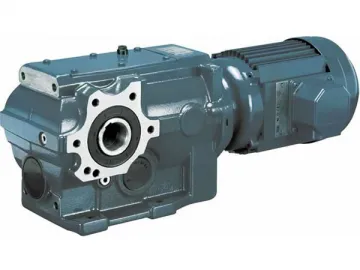

| Drive method | Double sided AC servo motor; Rack and pinion transmission system |

| Lengthways rail length | 4500-7500 mm |

| Effective cutting length | 1500 mm less than the rail length |

| Idle running speed | 12000 mm/min |

| Cutting speed | ≤6000 mm/min |

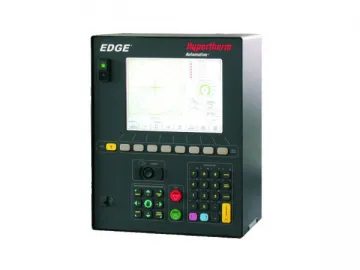

| CNC system | Imported CNC system |

| Cutting torch number | 1 |

| Cutting thickness | 0.3-2 mm |

Cutting sample

Links:https://www.globefindpro.com/products/43981.html

-

CNC Flame/Plasma Cutting Table

CNC Flame/Plasma Cutting Table

-

Reducer for Glass Lined Reactor

Reducer for Glass Lined Reactor

-

Power Supply for Plasma Cutting

Power Supply for Plasma Cutting

-

Underwater CNC Plasma Cutting Machine

Underwater CNC Plasma Cutting Machine

-

CNC System

CNC System

-

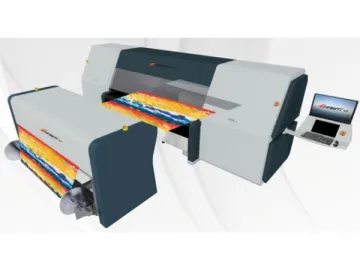

FY-1816TX 4-Color/8-Color Textile Printer

FY-1816TX 4-Color/8-Color Textile Printer

-

CNC Laser/Plasma Cutting Table

CNC Laser/Plasma Cutting Table

-

CNC Plasma Cutting and Drilling Machine

CNC Plasma Cutting and Drilling Machine

-

Glass Lined Multi-tube Heat Exchanger

Glass Lined Multi-tube Heat Exchanger

-

Glass Lined Manhole

Glass Lined Manhole

-

FY-3278N 4-Color Outdoor Solvent Printer

FY-3278N 4-Color Outdoor Solvent Printer

-

Dry CNC Plasma Cutting Machine

Dry CNC Plasma Cutting Machine