Single Sided Driven CNC Flame Cutting Machine

Description

The single sided driven CNC flame cutting machine was developed 16 years ago. The technology solution and processing technique are both pretty mature. This machine works well in the cutting operation of carbon steel plate whose width is 1500-3000 mm and the thickness is 6-300 mm. The workpiece cut by our machine has smooth cutting edge, rectangle edges, great precision, and the whole cutting process produce limited pollution. Comparing to the plasma cutting, flame cutting costs less, so this CNC cutting machine is very popular at home and abroad.

Advantage

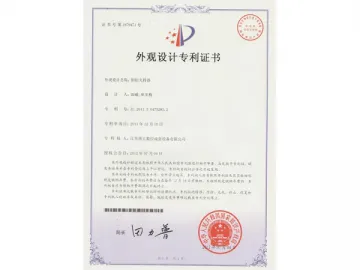

1. The cutting torch holder has been awarded the certificate of "National appearance design patent".

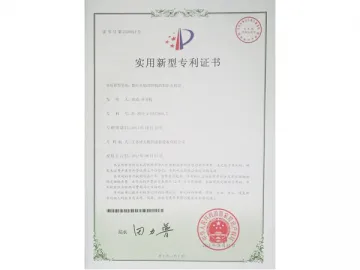

2. The cutting torch lifting structure has been granted the "utility model patent certificate of China"

3. The cutting torch holder has been granted the "utility model patent certificate of China"

4. Great precision.

The girder of our single sided driven CNC flame cutting machine is processed by large size CNC gantry machining center which is made in Taiwan. This gantry machining center can process a 9.5m cross beam by once forming technique, and the precision is outstanding comparing with both domestic and imported machines. This machining center is worth 6 million RMB, it is a powerful machine for manufacturing large machines, while the processing speed is also quite desirable. The once forming technique used for the girder guaranteed the cutting operation’s stability.

5. Steel powder-free cutting operation.

The cutting is conducted by melting the steel sheet at high temperature which is created by the burning of gas in oxygen. So no powder will be produced, and damage to worker’s health will be avoided.

6. Easy operation.

Fast CAM nesting software is used for this steel plate cutting machine. Waste material will be remarkably reduced and the cost will be perfectly controlled.

7. Beveled edge-free.

The guide bar of the lift device is double linear cylinder rails, ensuring the stability when it is moving up and down.

8. Long service life of the circuit.

The electric circuit of the single sided driven CNC flame cutting machine is well protected by cable sheath, so its service life is greatly lengthened.

Machine parameter

| Transverse rail interval | 2500-4000 mm |

| Effective cutting width | 1500-3000 mm |

| Driving technique | Single sided AC servo motor; Rack and pinion transmission system |

| Effective cutting length | 3000 mm shorter than the rail length |

| Idle running speed | ≤6000 mm/min |

| Cutting speed | 100-750 mm/min |

| CNC system | BODA CNC or imported CNC system |

| Cutting torch number | 1-4 |

| Minimum cutting torch interval | 200 mm |

| Cutting thickness | 6-300 mm |

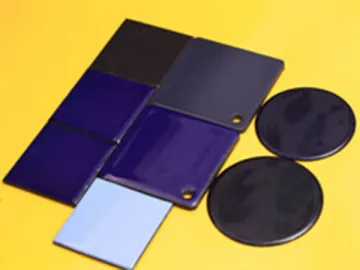

Cutting sample

Links:https://www.globefindpro.com/products/43996.html

-

Glass Lined Flush Valve

Glass Lined Flush Valve

-

Simple Single Sided Driven Flame Cutting Machine

Simple Single Sided Driven Flame Cutting Machine

-

Strips Flame Cutting Machine

Strips Flame Cutting Machine

-

Open-type Glass Lined Reactor

Open-type Glass Lined Reactor

-

CDH-80 Toilet Roll Packing Machine

CDH-80 Toilet Roll Packing Machine

-

CD-1575D Non Woven Slitter Rewinder

CD-1575D Non Woven Slitter Rewinder

-

CNC Precision Plasma Cutting Machine

CNC Precision Plasma Cutting Machine

-

Robot Arm Laser Cutting Machine

Robot Arm Laser Cutting Machine

-

Cutting Accessories

Cutting Accessories

-

Close-type Vertical Glass Lined Storage Tank

Close-type Vertical Glass Lined Storage Tank

-

Double Sided Driven CNC Flame Cutting Machine

Double Sided Driven CNC Flame Cutting Machine

-

Glass Lined Agitator

Glass Lined Agitator