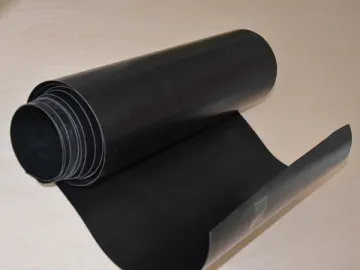

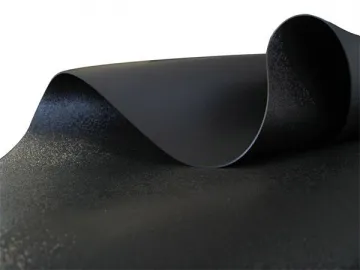

HDPE Textured Geomembrane

Our HDPE textured geomembrane comes in two different models: one with a single textured surface, the other with a double textured surface. Because of its strong tribological properties in which the textured surface increases friction between two surfaces, this geosynthetic liner works well for steep slopes. Therefore, as compared with smooth surface impermeable liners that often serve as HDPE pond liners, landfill liners, etc., this line of HDPE geomembrane is more often used as dam liners.

Instead of extrusion and secondary processing, we use co-extrusion technology to manufacture the HDPE textured geomembrane. A textured surface is layered upon a base, which is then extruded into a strong temperature and chemical resistant layer which won't be affected by heat, chemicals, or external forces. This textured geomembrane conforms to CJT234-2006 standards (High Density Polyethylene Geomembrane for Landfills).

Technical Parameters

| Item | Test value | ||||

| 1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm | |

| Roughness height, mm | 0.25 | ||||

| Min. density, g/cm3 | 0.939 | ||||

| Tensile property | |||||

| Yield strength (stress) N/mm | 15 | 18 | 22 | 29 | 37 |

| Breaking strength (stress) N/mm | 10 | 13 | 16 | 21 | 26 |

| Elongation at yield, % | 12 | ||||

| Elongation at break, % | 100 | ||||

| Tear resistance, N | 125 | 156 | 187 | 249 | 311 |

| Puncture resistance N | 267 | 333 | 400 | 534 | 667 |

| Stress crack resistance (single-point incision, dead load stretch), hrs | 300 | ||||

| Carbon black | |||||

| Carbon black content, % | 2.0-3.0 | ||||

| Carbon black dispersion | 1 or 2 (9 in 10 times) 3 (less than 1 time) | ||||

| Oxidative induction time (OIT) | |||||

| Standard OTI, min. | 100 | ||||

| High pressure OTI, min. | 400 | ||||

| Oven ageing at 85℃ (min. average value) | |||||

| Standard OTI reservation after 90 days, % | 55 | ||||

| High pressure OTI reservation after 90 days, % | 80 | ||||

| UV protection | |||||

| Standard OTI reservation after 1600 hours of ultraviolet radiation, % | 50 | ||||

| High pressure OTI reservation after 1600 hours of ultraviolet radiation, % | 50 | ||||

| Impact and embrittlement performance at -70℃ | Pass | ||||

Links:https://www.globefindpro.com/products/44235.html