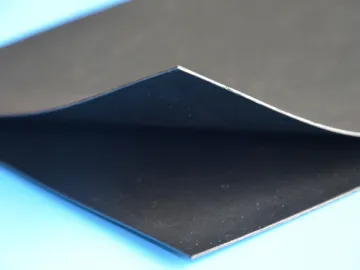

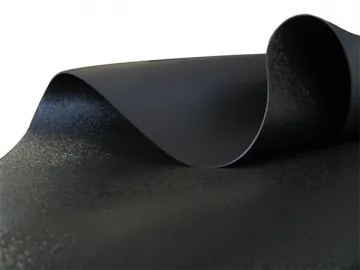

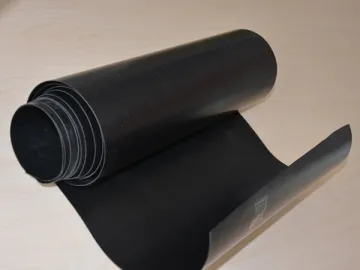

HDPE Geomembrane

Our HDPE geomembranes begin as raw polyethylene resin which is then processed into flexible HDPE liners. This geomembrane liner is widely used in mines, ponds, dams, solid waste disposal sites and other industries requiring geosynthetic liners because of its low permeability and strong corrosion resistance. Because it won't wear out easily with weather or chemicals, our HDPE geomembrane is often used for outdoor water storage projects. Customized HDPE geomembranes with different colors, including black, white and bicolor composite liners are also available.

Technical Parameters

| No. | Item | Test Value | ||||||

| 0.75mm | 1.0mm | 1.25mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | ||

| 1 | Minimum Density (g/cm3) | 0.939 | ||||||

| 2 | Tensile Property | |||||||

| Strength at yield, N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

| Strength at break, N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

| Elongation at yield (%) | 12 | |||||||

| Elongation at break (%) | 700 | |||||||

| 3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

| 4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

| 5 | Stress Crack Resistance (hrs) | 300 | ||||||

| 6 | Carbon Black Content (%) | 2.0-3.0 | ||||||

| Carbon Black Dispersion | 1 or 2 | |||||||

| 7 | Standard OTI (min.) | 100 | ||||||

| High Pressure OTI (min.) | 400 | |||||||

| 8 | Impact Cold Crack at -70℃ | Pass | ||||||

| 9 | Water Vapor Permeability (g.cm/cm2.s.Pa) | ≤1.0×10-13 | ||||||

| 10 | Dimensional Stability (%) | ±2 | ||||||

Scan QR to Read

Links:https://www.globefindpro.com/products/44241.html

Links:https://www.globefindpro.com/products/44241.html

Recommended Products

Hot Products